Whole seal type highly effective air purification air supply outlet

A high-efficiency air and air outlet technology, applied in space heating and ventilation details, duct layout, household heating, etc., can solve the problems of inconvenient installation, inconvenient operation, engineering loss, etc., to achieve convenient installation and disassembly, easy handling and Installation, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

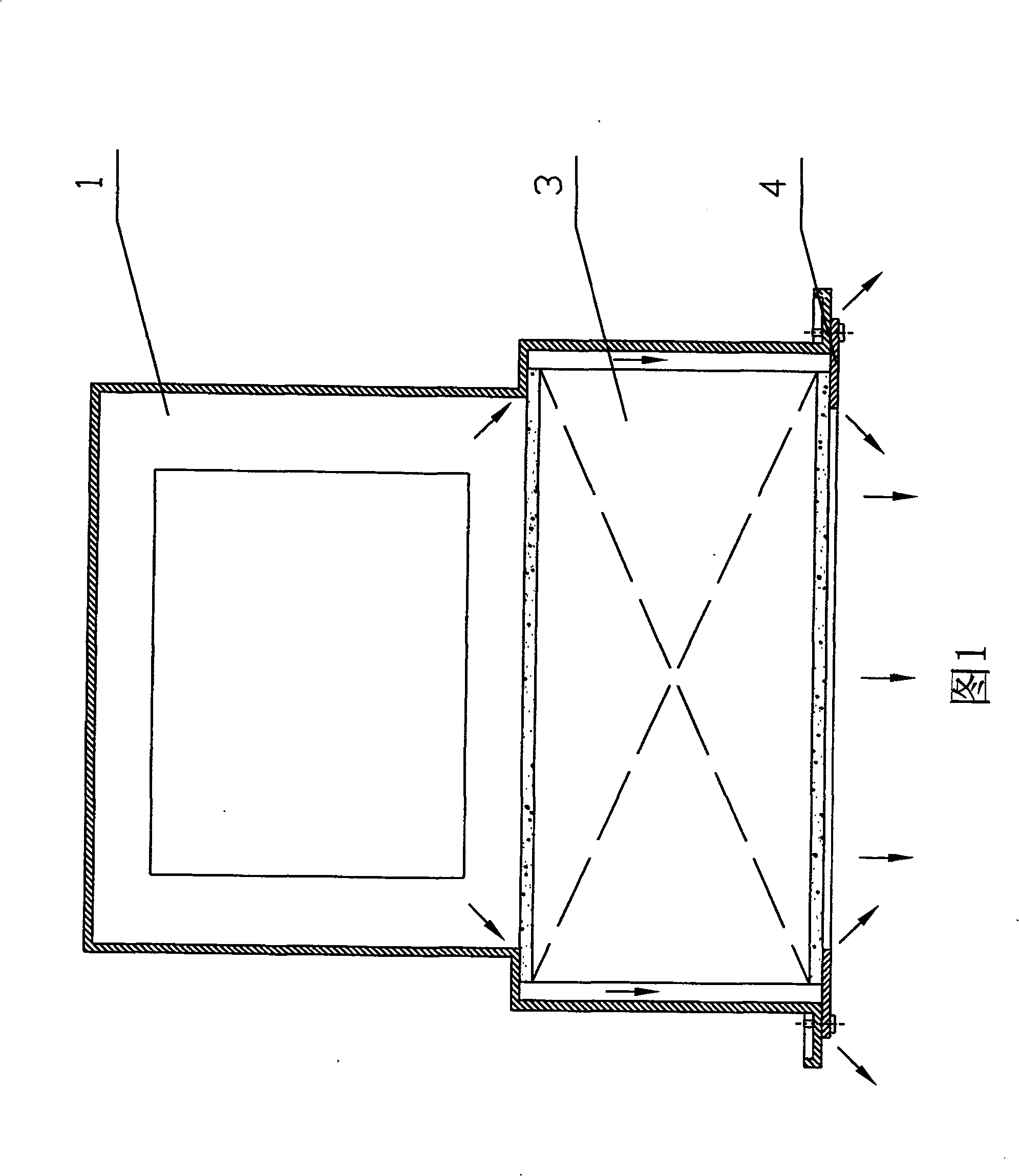

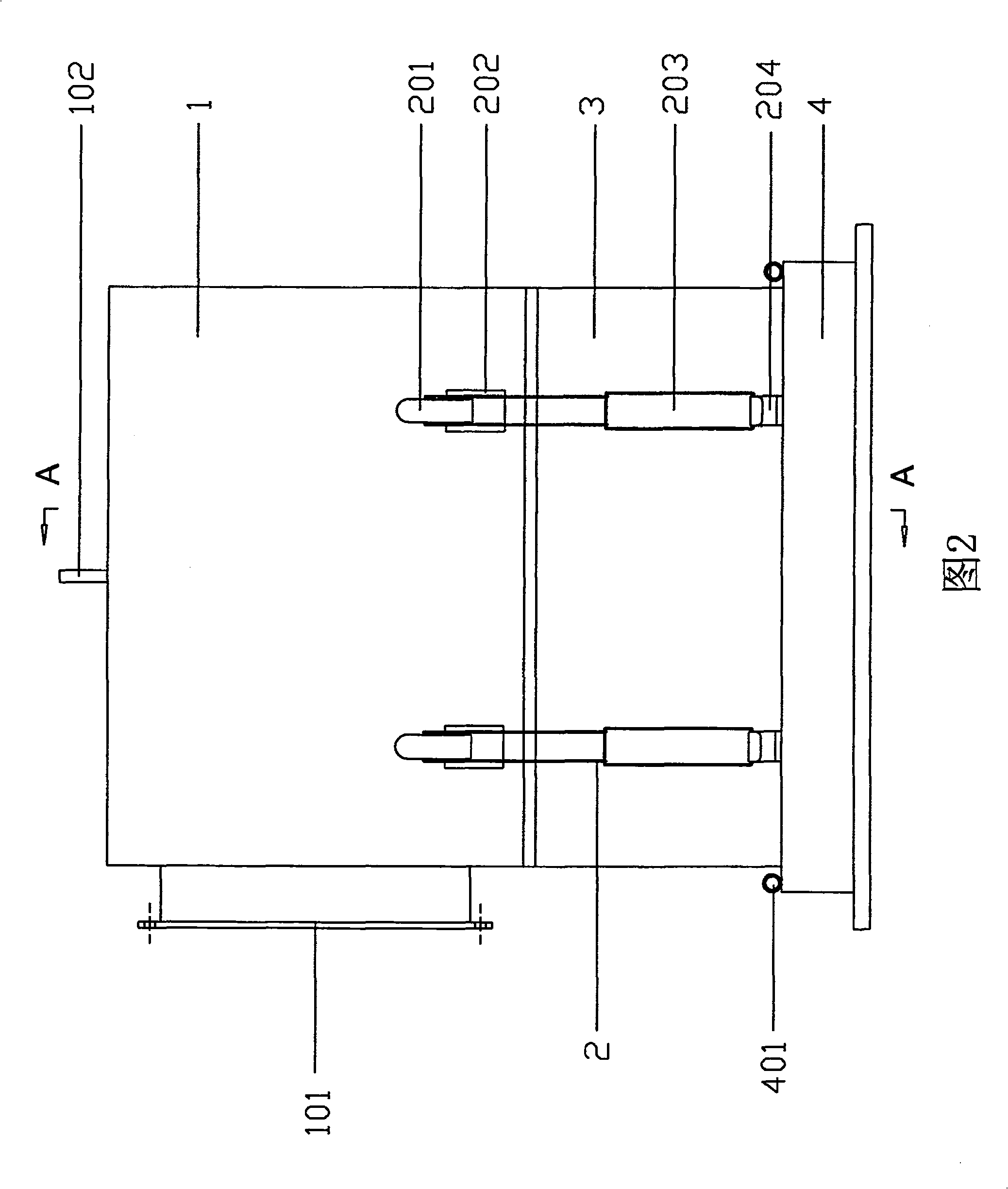

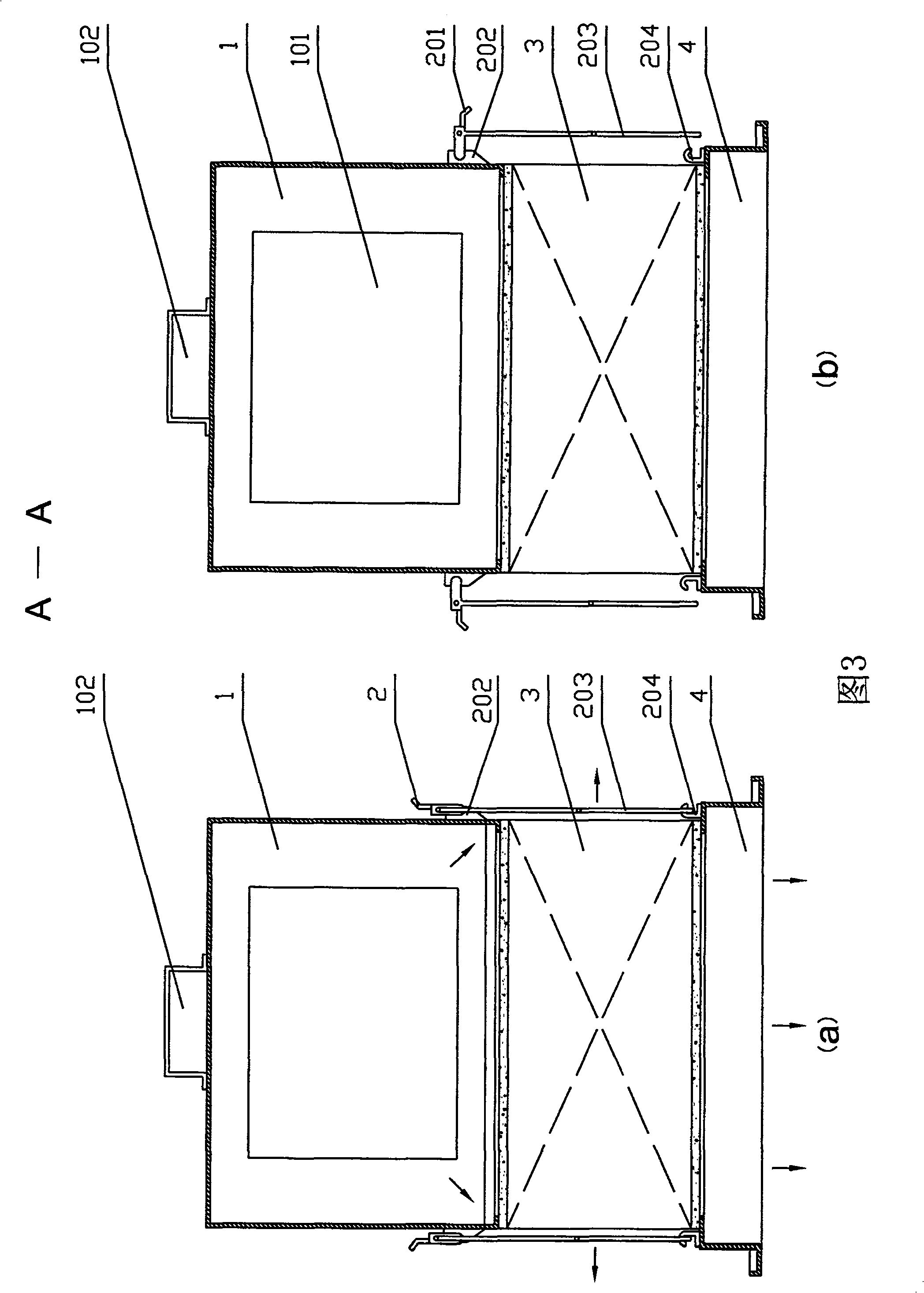

[0019] refer to figure 2 , image 3 As shown in (a) and (b), a fully sealed high-efficiency air purification air outlet is mainly composed of static pressure box 1, pressing buckle device 2, high-efficiency filter 3, base 4 and other parts; its static pressure An air inlet 101 is provided on one side of the cabinet 1, and a lifting handle 102 is provided on the top. The static pressure cabinet 1 and the high-efficiency filter 3 are arranged stacked up and down, and are pressed on the base 4 by the compression buckle device 2. The base 4 Hanging ring 401 is arranged on it.

[0020] The pressing buckle device 2 includes a handle 201, a handle base 202, a telescopic rod 203, a buckle 204, etc.; the base 202 is fixedly connected to both sides of the static pressure box 1, and the base 202 is movably connected by a pin shaft. Move the handle 201, move the handle 201 to connect the telescopic rod 203 through the pin shaft, the telescopic rod 203 adopts the prior art, the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com