Optical lens set and its molding method and corresponding model establishing device

An optical lens and lens technology, applied in optics, optical components, installation, etc., can solve the problems of increasing lens manufacturing cost and high cost, and achieve the effect of reducing processing cost and increasing the number of moldings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

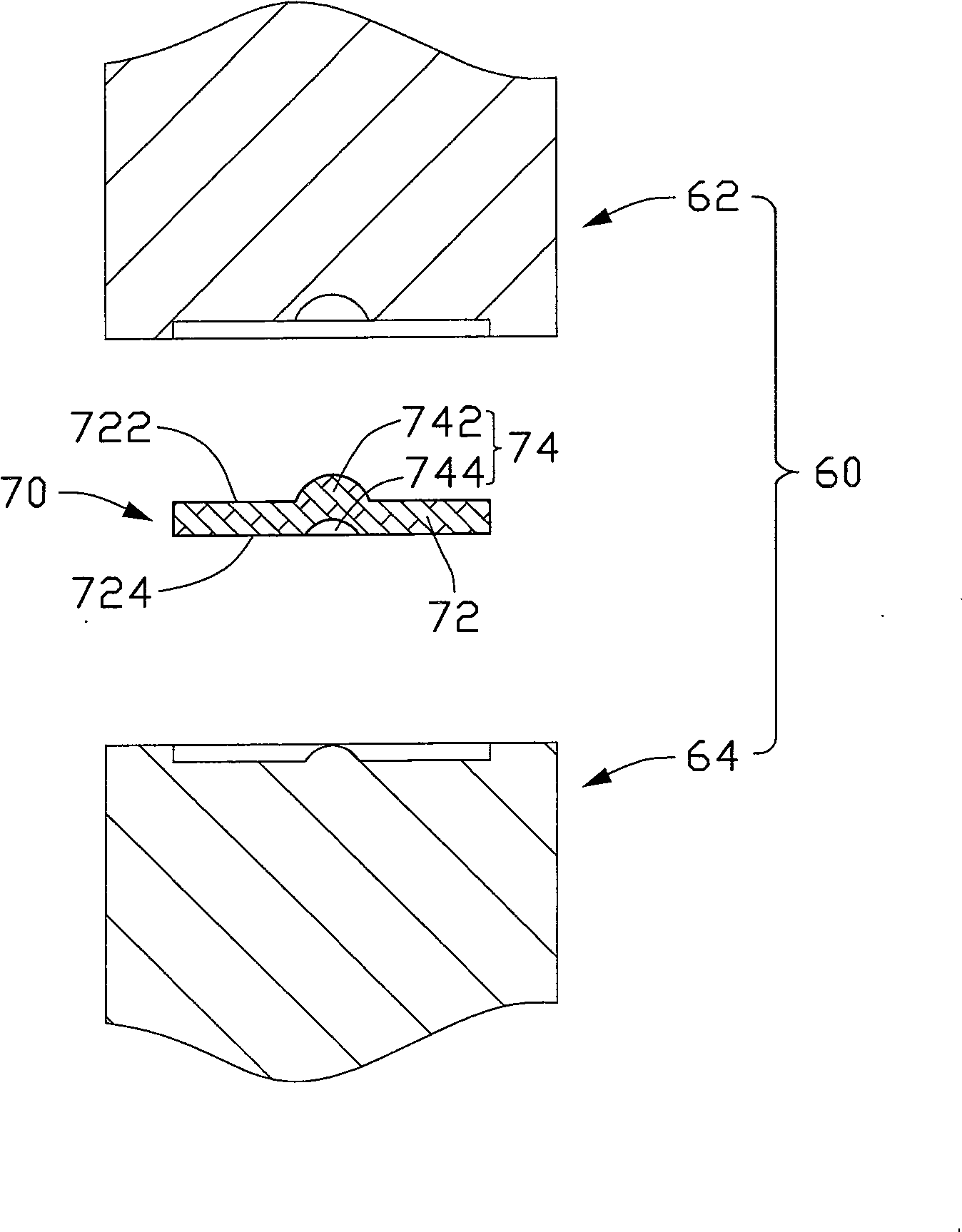

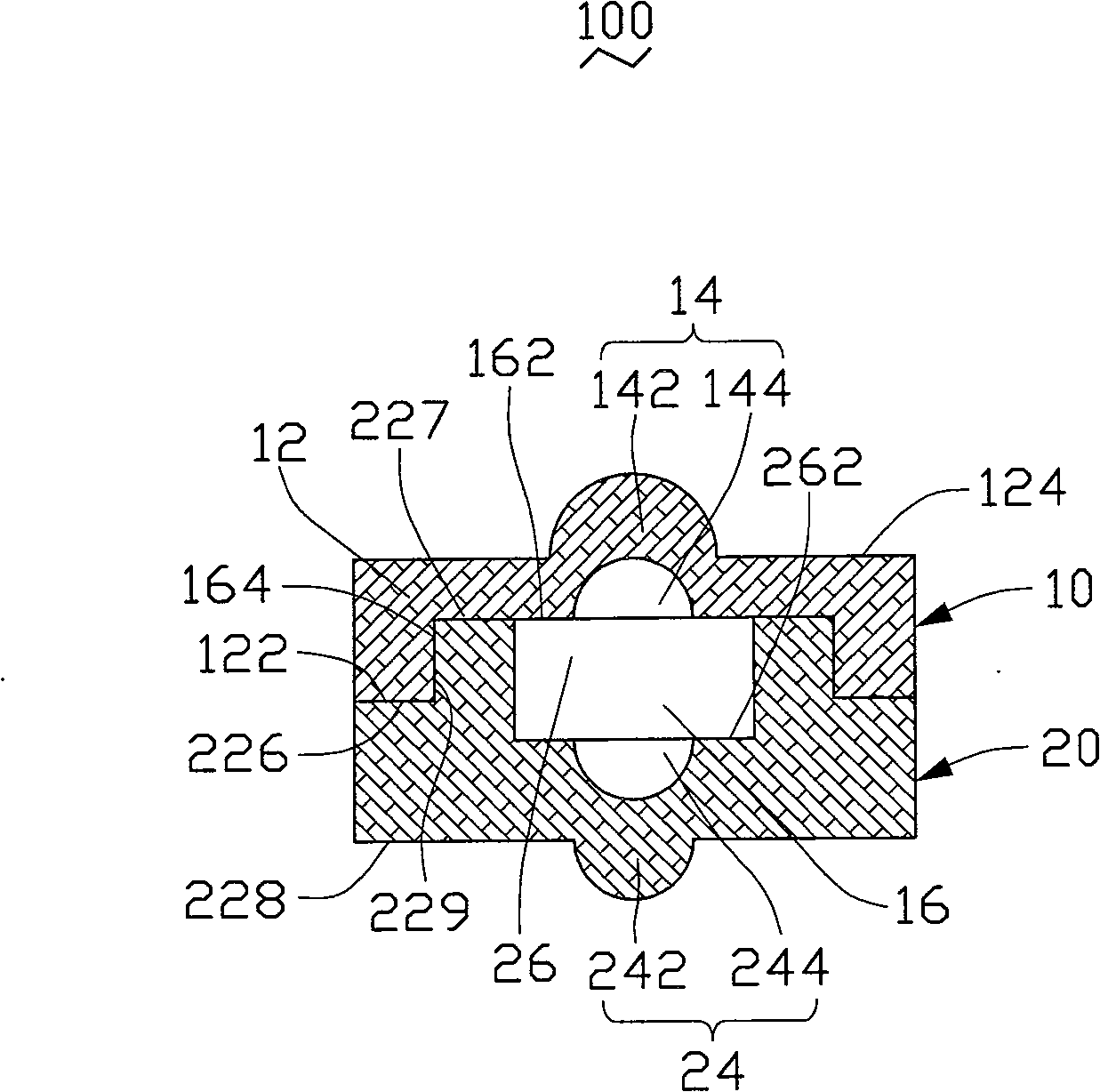

[0022] see figure 2 According to a preferred embodiment of the present invention, an optical lens set 100 includes a first lens 10 and a second lens 20, and the first lens 10 and the second lens 20 can be installed in a digital camera module (not shown).

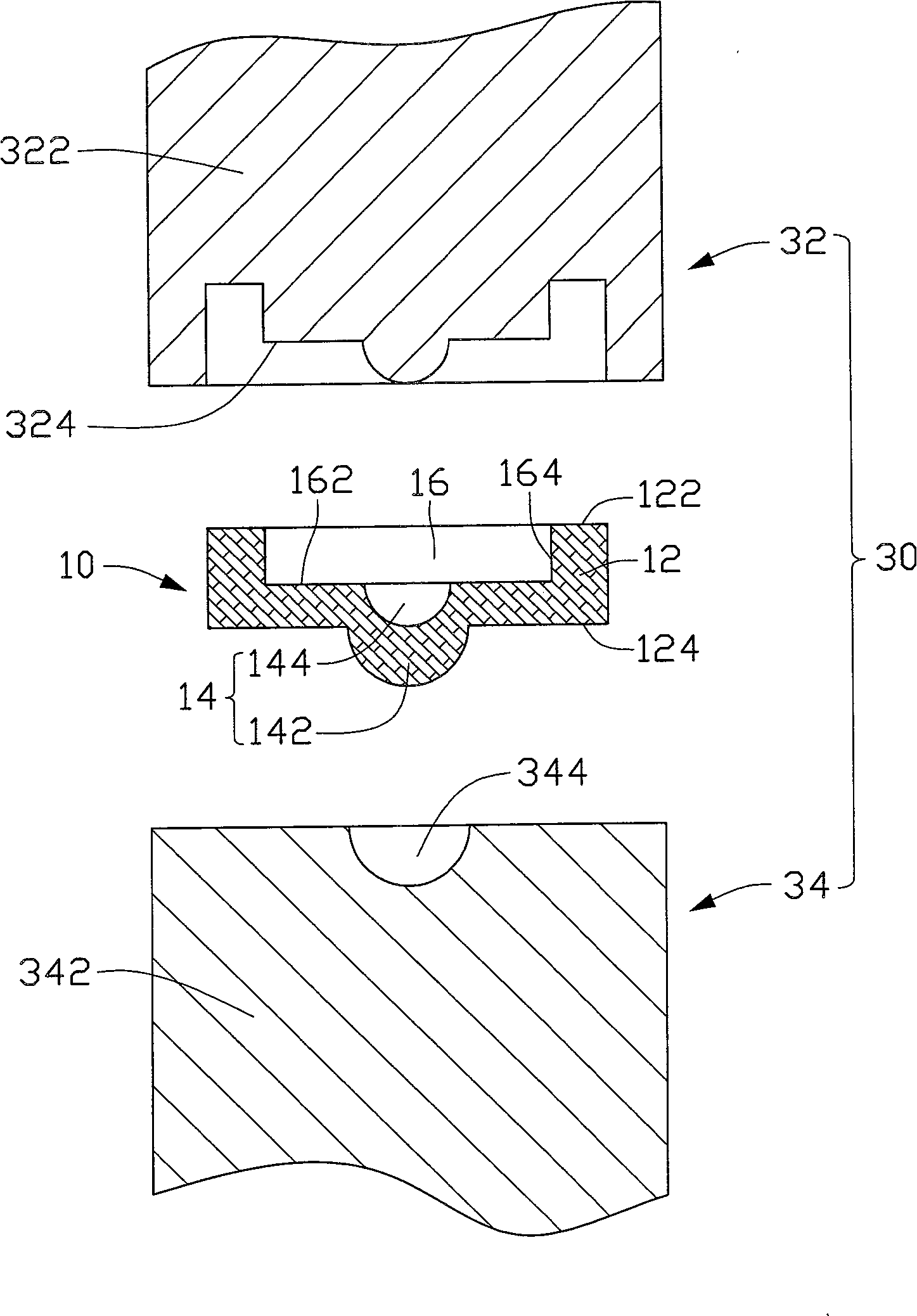

[0023] Please refer to image 3 , the first lens 10 includes a mounting portion 12 and an optical portion 14, the optical portion 14 is located in the middle of the mounting portion 12 and integrally formed with it. The mounting portion 12 of the first lens 10 is a hollow cylinder having a first end surface 122 and a second end surface 124 . A cylindrical cavity 16 is vertically defined in the middle of the first end surface 122 of the first lens 10 , and the cavity 16 has a bottom wall 162 and a side wall 164 . The optical portion 14 of the first lens 10 includes a convex body 142 and a groove 144 corresponding thereto; the surface of the convex body 142 is an aspherical surface, which is located in the middle of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com