Liquid crystal projector, its liquid crystal panel, and its liquid cooler

A technology for liquid crystal panels and projectors, used in projection devices, instruments, optics, etc., can solve problems such as insufficient and insufficient, and achieve excellent effects, good projected images, lifespan and reliability guarantees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

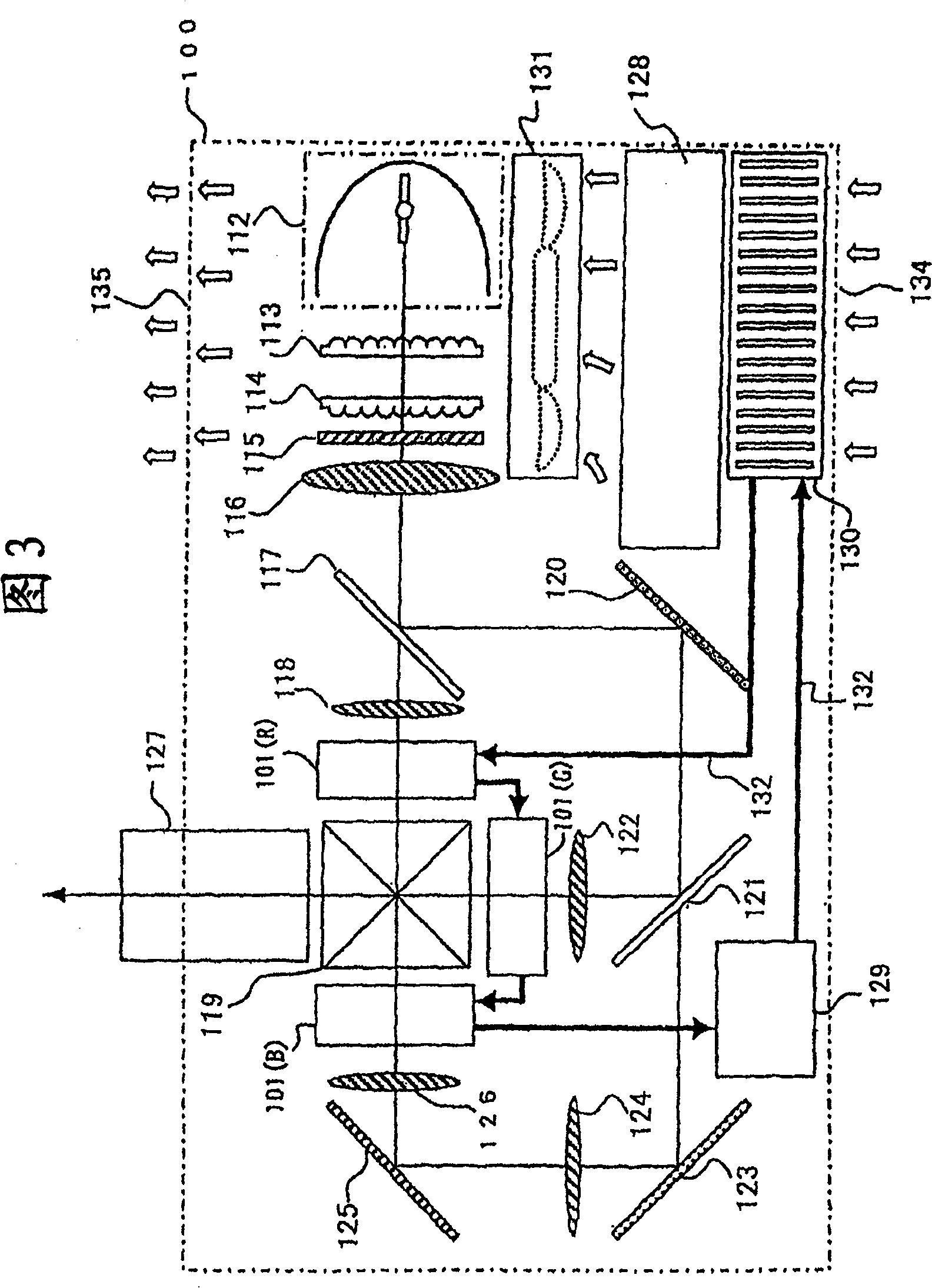

[0047] first, image 3 An example of the overall configuration of a liquid crystal projector including a liquid cooling device for a liquid crystal panel according to an embodiment of the present invention is shown. In the figure, symbol 100 represents the casing of the liquid crystal projector, and as shown in the figure, a light source, such as a metal halide lamp 112 , is arranged inside it. The light emitted by the light source 112 is output as parallel light by the first lens array 113, the second lens array 114, the polarization conversion element 115, and the condenser lens 116 arranged at predetermined positions in the housing. Then the parallel light is introduced into the first dichroic mirror 117, a part of which passes through the first dichroic mirror 117, passes through the first condenser lens 118, and then is introduced into the R (red) liquid crystal panel 101 (R), where the light intensity is modulated, Then it reaches the light-synthesizing prism 119 .

[0...

Embodiment 2

[0071] Embodiment 2 of the present invention will be described below with reference to the drawings. In this second embodiment, the same constituent elements as those of the above-mentioned first embodiment are denoted by the same symbols.

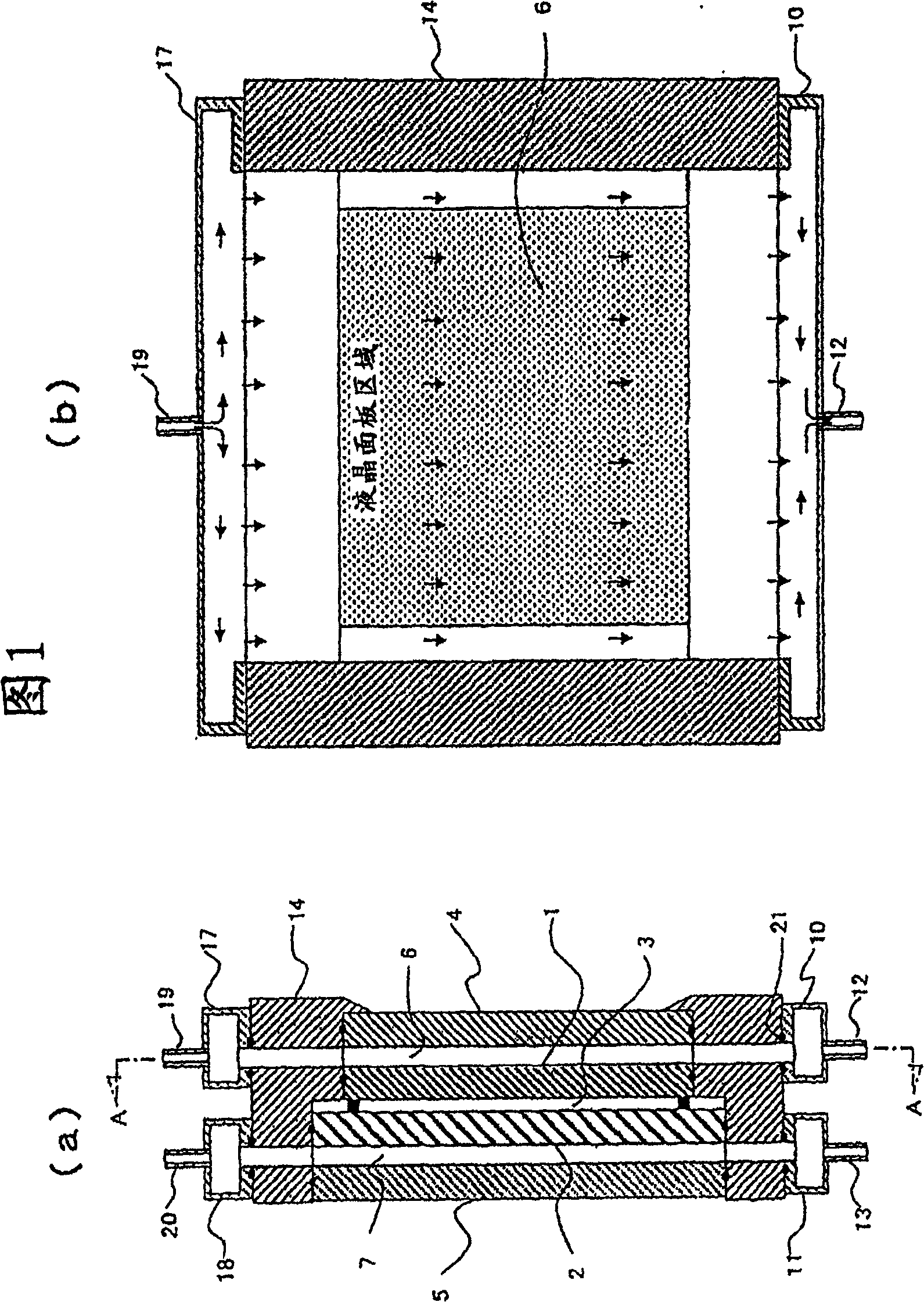

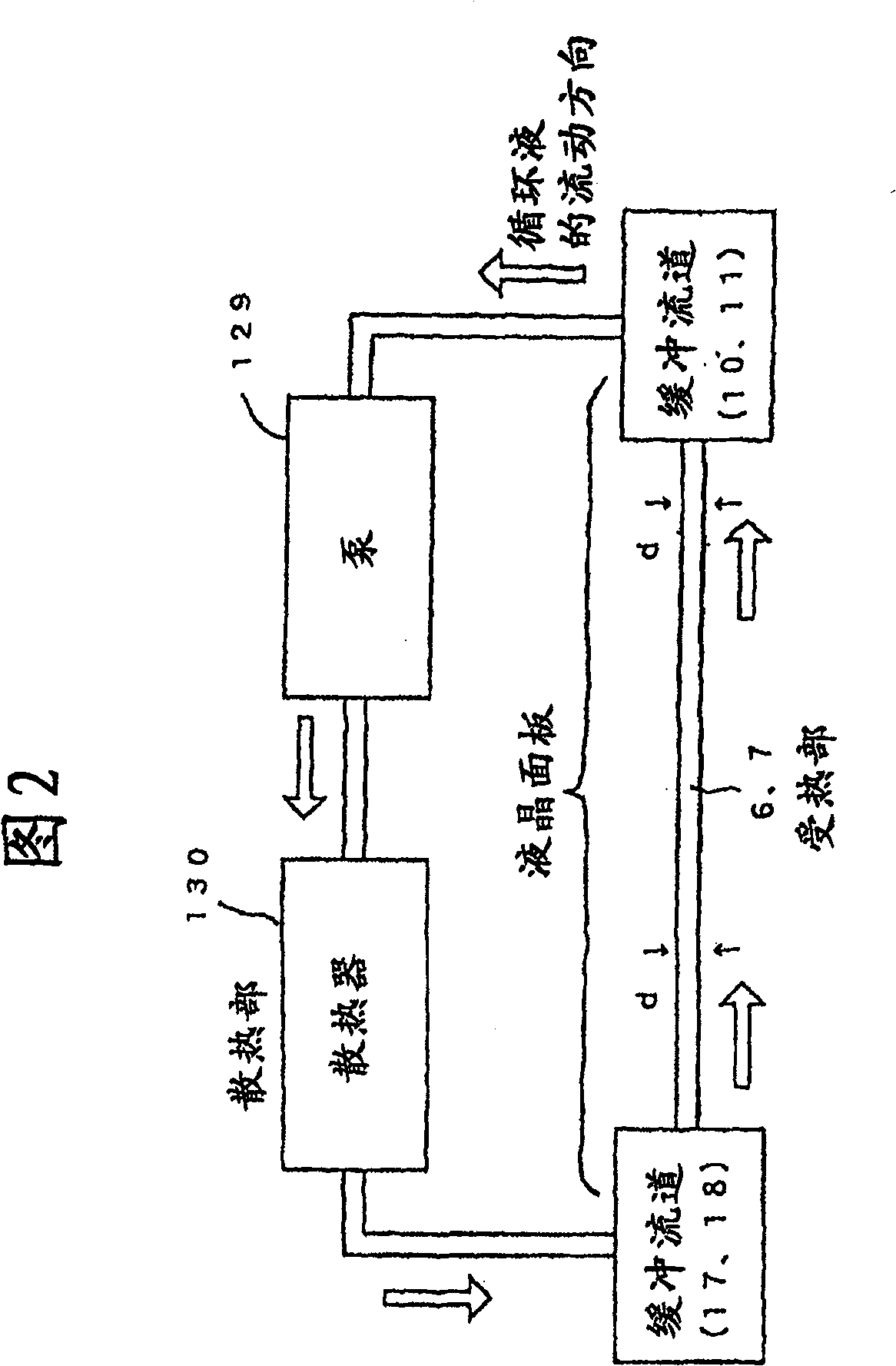

[0072] Figure 8 The detailed internal structure of one liquid crystal panel 101 among the liquid crystal panels 101 (R), 101 (G), and 101 (B) for R, G, and B described above is shown. First, a section showing a cross section of the liquid crystal panel 101 Figure 8 Reference numeral 2 in (a) represents the main structural elements of the liquid crystal panel 101, which is a TFT substrate made of glass, for example, on which a plurality of transistor drive elements are formed on the surface, and an opposing substrate made of glass is provided opposite to the TFT substrate. 1, and then seal the liquid crystal 3 between these transparent substrates 2, 1, thereby forming a liquid crystal panel 101 of one of the three primary colors of R, G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com