Offshore platform integral constructing and hoisting method and special-purpose hoisting machine for the same

A technology for offshore platforms and hoisting methods, which is applied to ship construction, cranes, and traveling mechanisms. It can solve problems such as difficult quality assurance, extended construction period, and inconvenient access to personnel, materials, and equipment, and reduce construction difficulty and workload. , Improve shipbuilding efficiency and output, and expand shipbuilding capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

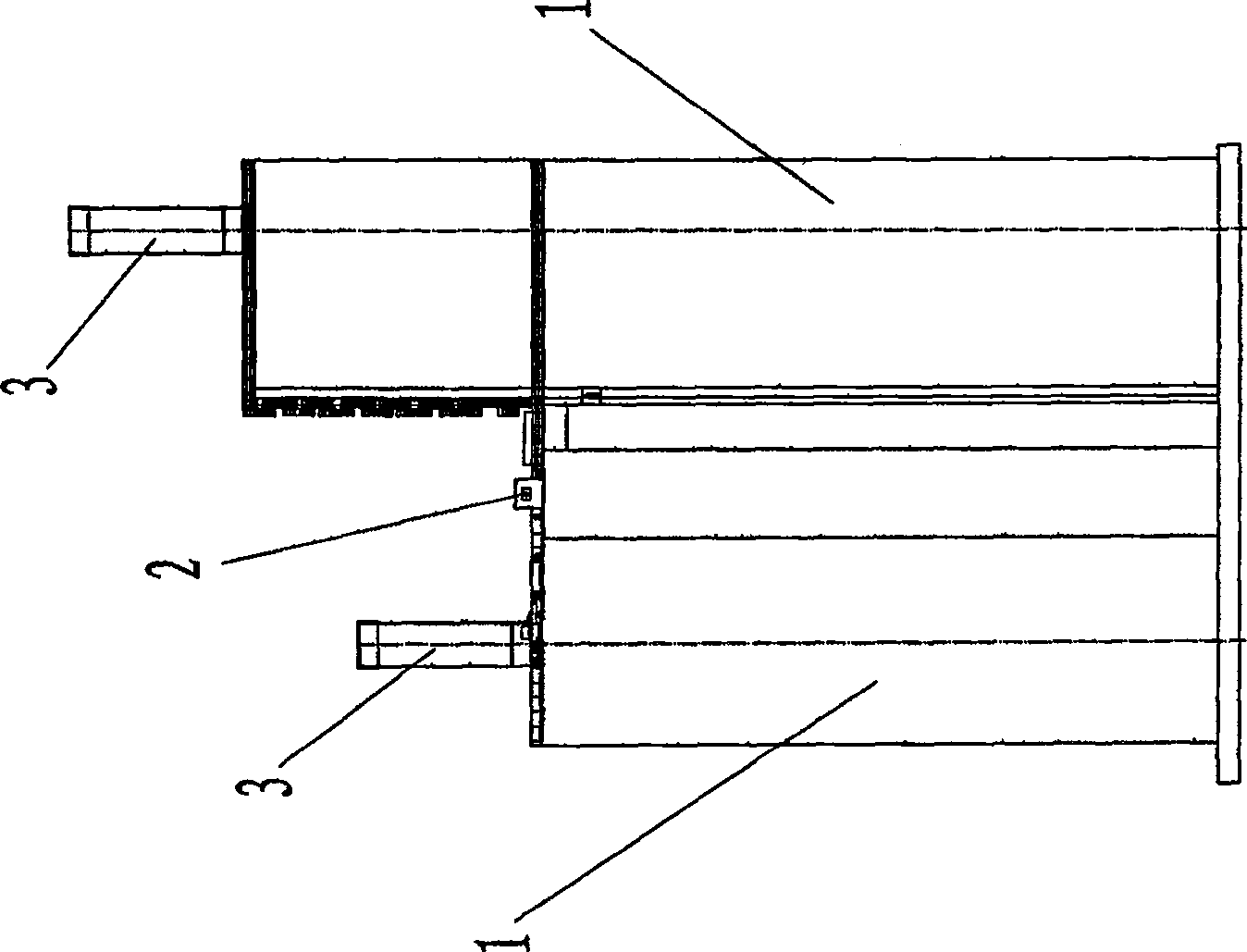

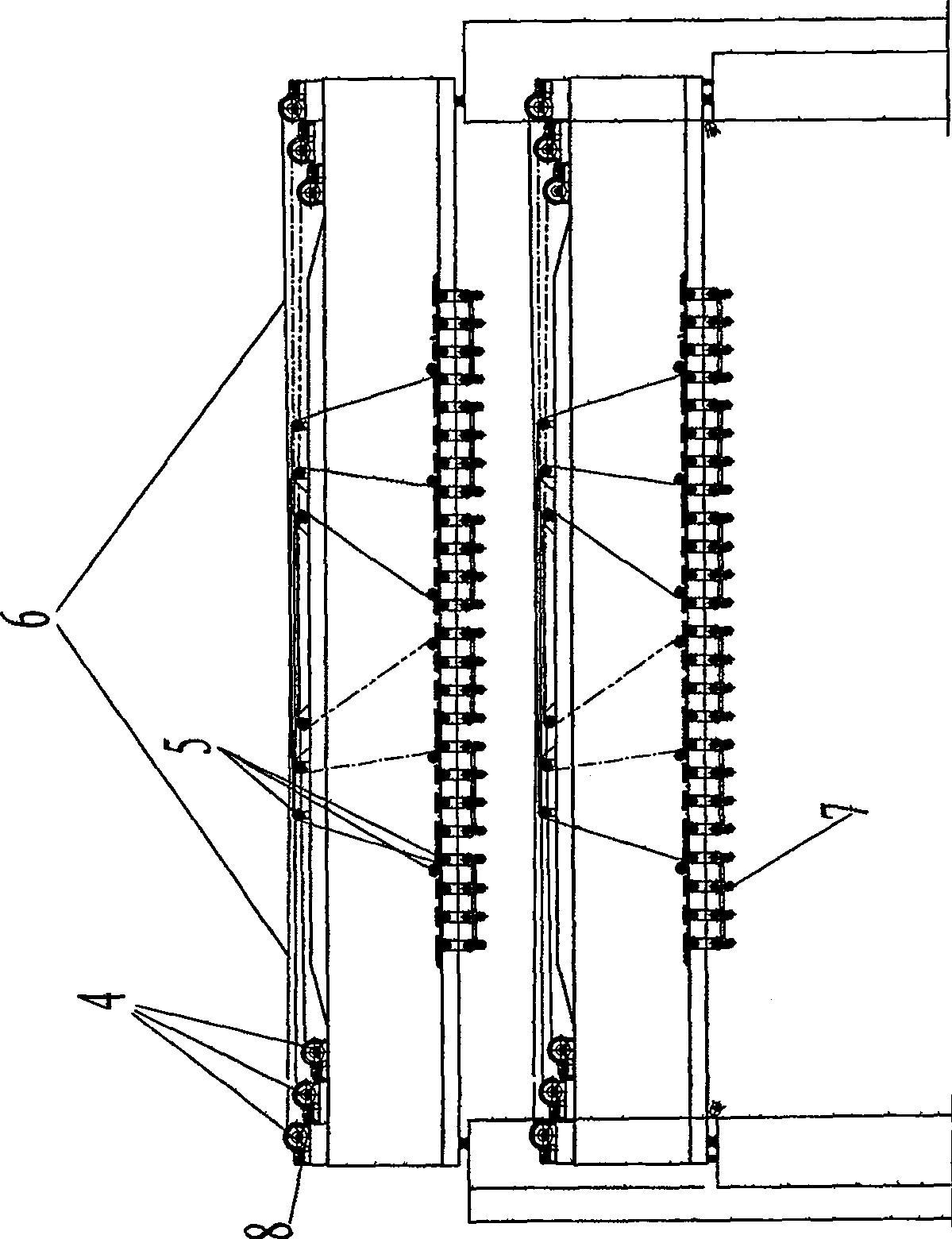

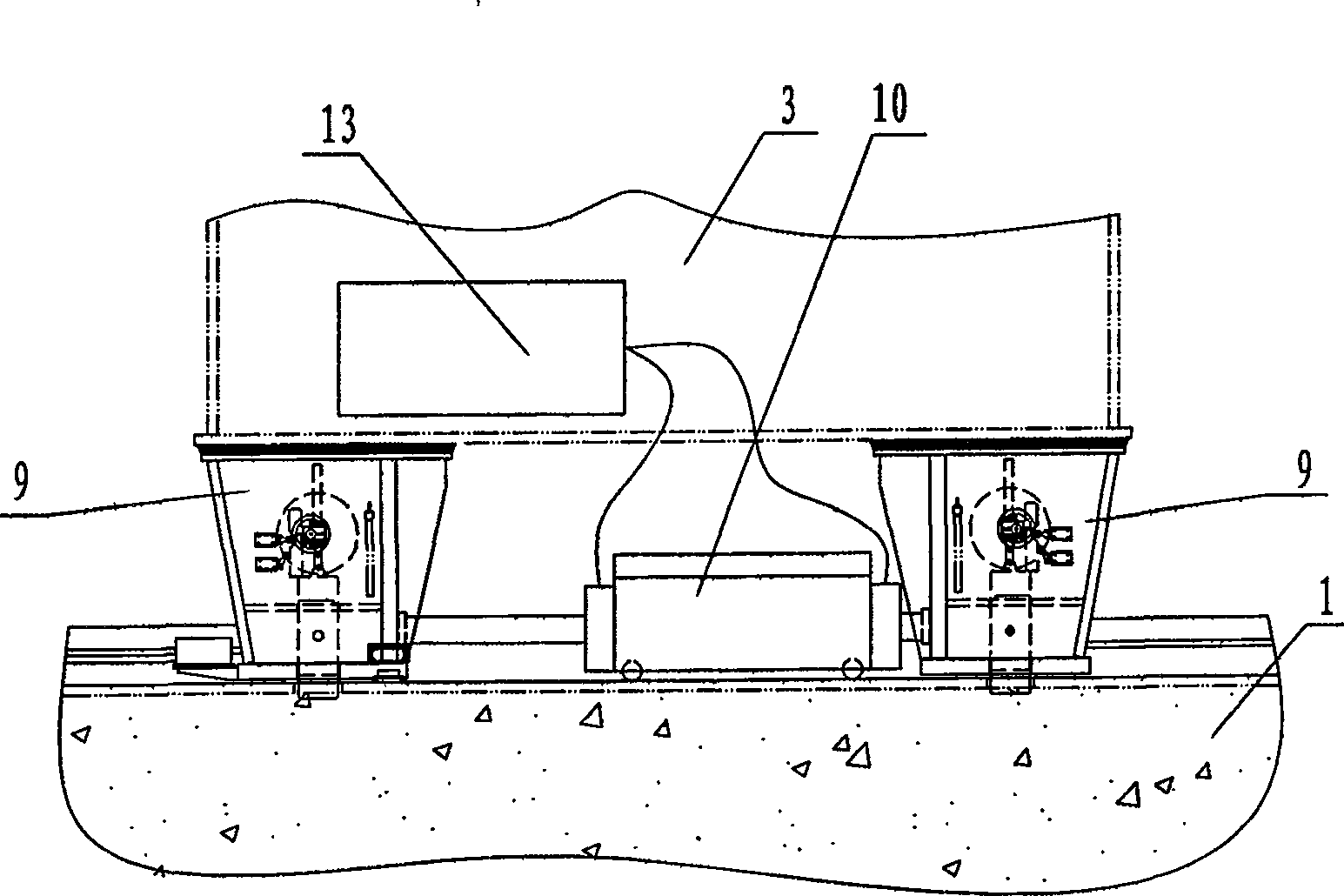

[0037] A method for integral construction and hoisting of an offshore platform, comprising firstly constructing the lower floating body of the platform on land according to the requirements of the drawing; at the same time, constructing the upper module of the platform on land according to the requirements of the drawing, and building the upper module of the platform as a whole; On the barge, the barge is towed to the designated area in the dock, sinks, the floating body floats naturally, and then the floating body is moved to the designated position; the upper module of the platform is launched onto the launching barge as a whole, the launching barge is dragged into the dock, the launching barge is positioned and Prepare for lifting; close the dock door; use a crane to hoist the upper module of the platform to a place higher than the lower floating body of the platform. The lifted upper module is lowered and positioned; the upper module is installed on the lower floating body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com