Method for laying structures of forming underground tunnel and its structure

A laying method and technology for underground tunnels, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as difficult construction, uneconomical construction, and slow construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

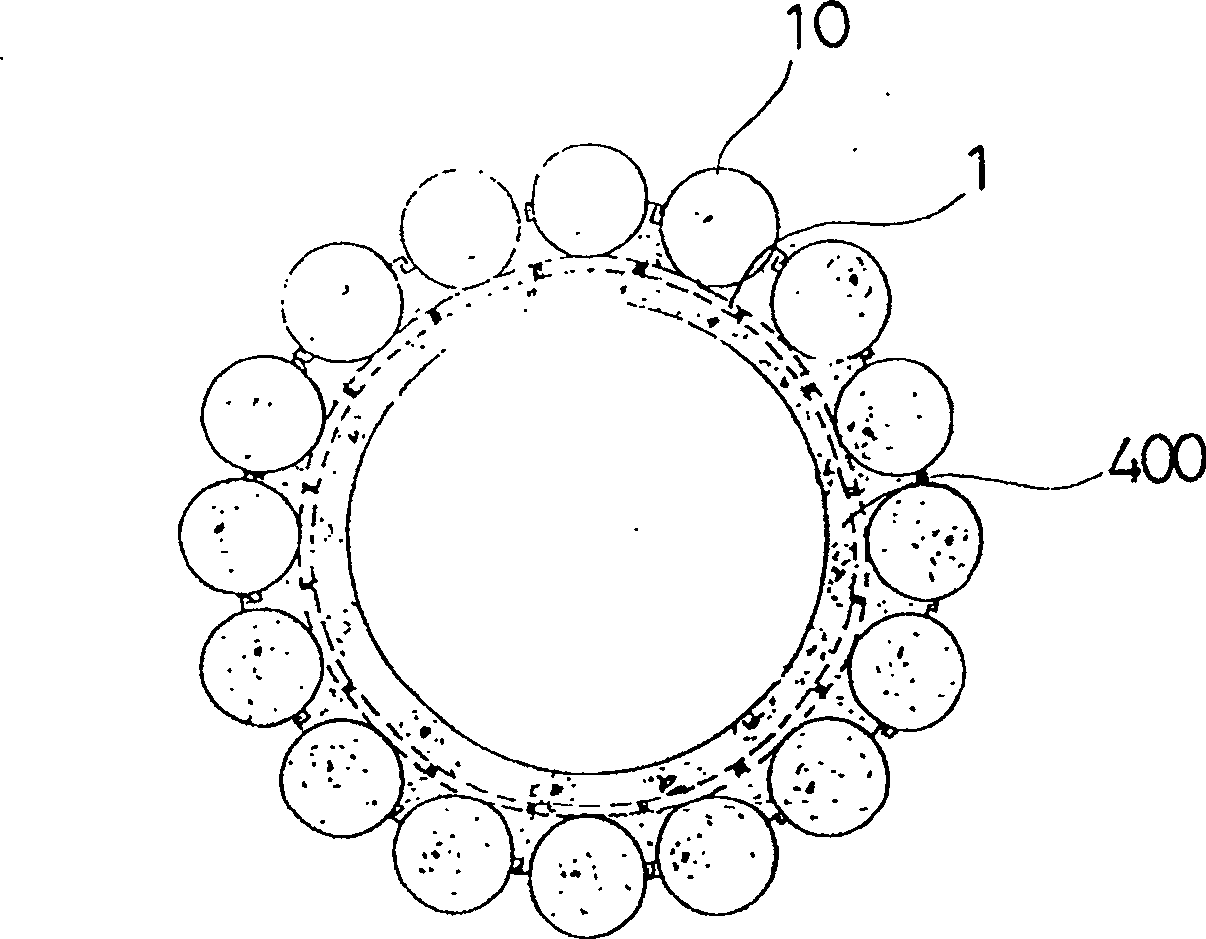

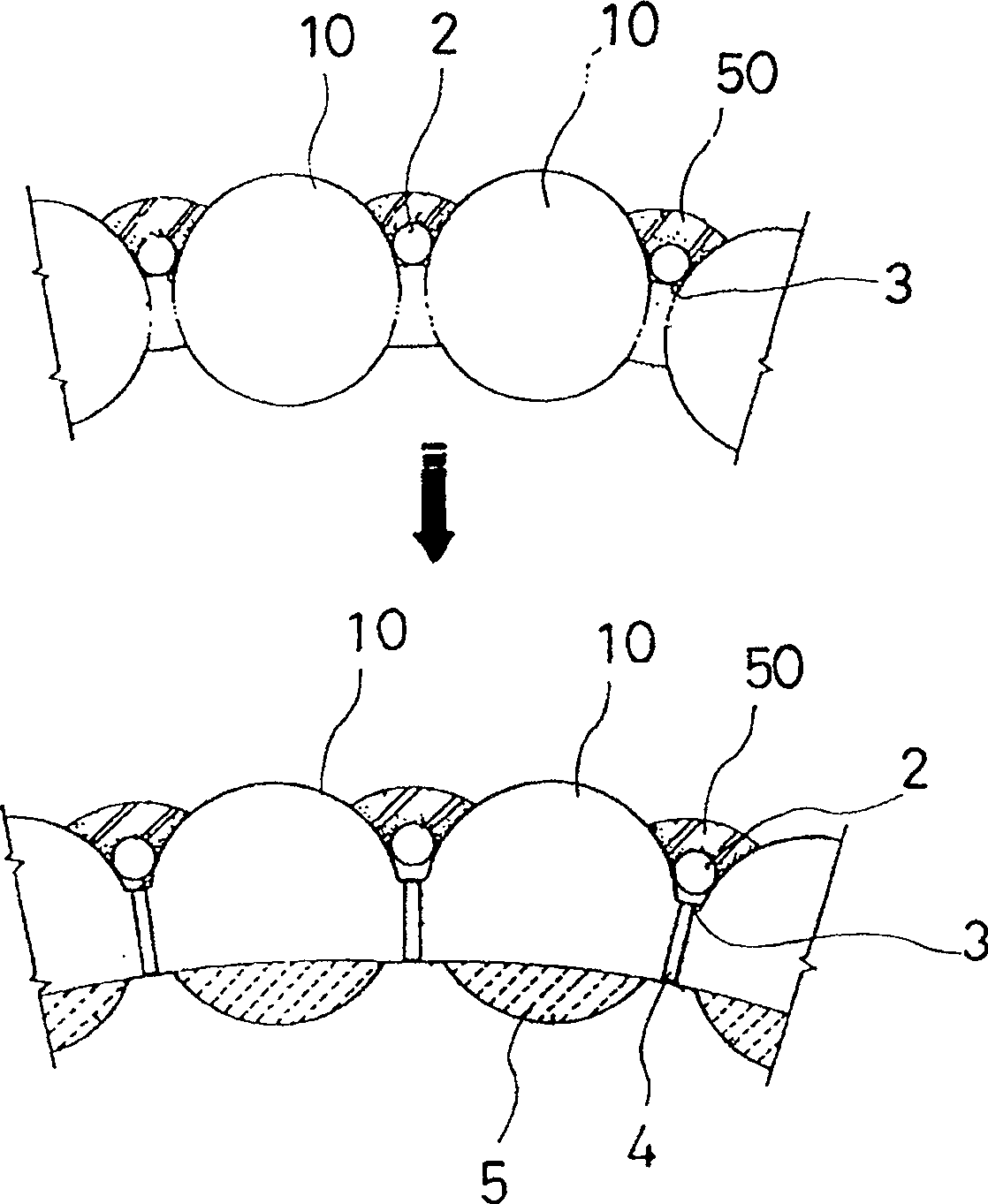

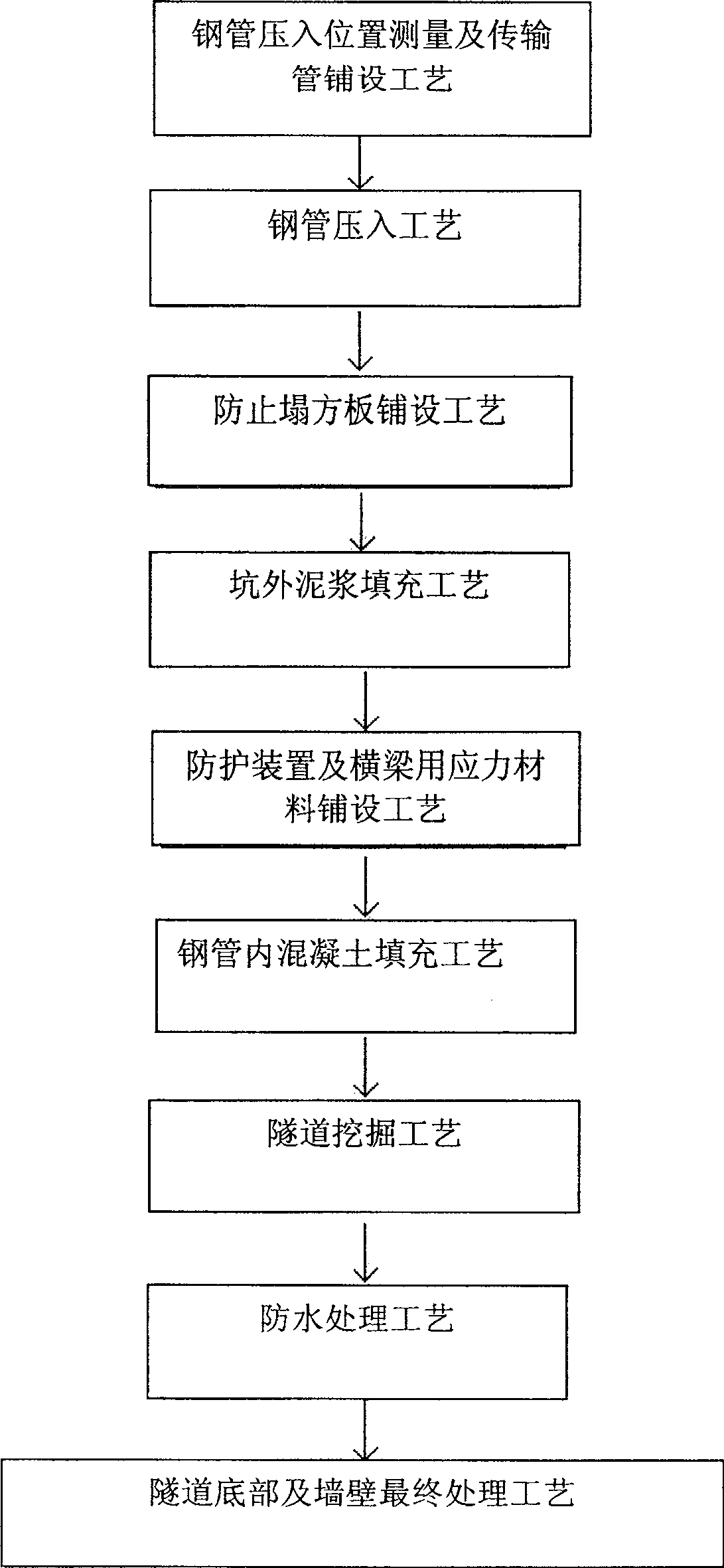

[0062] refer to image 3 process diagrams involved, with Figure 4 , Figure 5a , Figure 5b based on Figure 6a , Figure 6b , the first embodiment of the present invention will be described in detail.

[0063] Steel pipe pressing position measurement and transmission pipe laying process A:

[0064] Before pressing into the steel pipe 10, accurate measurement is carried out at the appropriate position according to the scheduled tunnel construction, and the input port 21 of the anti-collapse plate is formed at the front end of the steel pipe 10, combined with the transmission pipe 20 with the pressing-in direction adjustment device 30, the pressing-in of the steel pipe is completed 10 preparations.

[0065] Steel pipe pressing process B:

[0066] Place the steel pipe 10 at the exact propulsion position, press it in step by step with the hydraulic jack and the propulsion auxiliary pipe, and measure the position every 1M, and use the press-in direction adjustment device 3...

Embodiment approach 2

[0082] refer to image 3 process diagrams involved, with Figure 4 , Figure 5a , Figure 5b based on Figure 7a , Figure 7b , the second embodiment of the present invention will be described in detail.

[0083] The second embodiment of the present invention uses the same method as the above-mentioned first embodiment, and sequentially performs steel pipe pressing position measurement, transmission pipe laying process A, steel pipe pressing process B, collapse prevention plate laying process C, and mud filling outside the pit After process D, process E of laying stress materials for protective devices and beams, process F of concrete filling in steel pipes, and process G of tunnel excavation:

[0084] Waterproof treatment process H:

[0085] A waterproof iron plate 120 is used to connect the steel pipe 10 on one side protruding from the tunnel portion 500 and the steel pipe 10 on the other side to prevent water from penetrating into the tunnel and to play a waterproof r...

Embodiment approach 3

[0089] refer to image 3 engineering drawings involved, with Figure 4 , Figure 5a , Figure 5b based on Figure 8a , Figure 8b , the third embodiment of the present invention will be described in detail.

[0090] The third embodiment according to the present invention uses the same method as the above-mentioned first embodiment, and sequentially performs steel pipe pressing position measurement, transmission pipe laying process A, steel pipe pressing process B, collapse prevention plate laying process C, and mud filling outside the pit After process D, process E of laying stress materials for protective devices and beams, process F of concrete filling in steel pipes, and process G of tunnel excavation:

[0091] Waterproof treatment process H:

[0092] Asphalt or a thin waterproof material layer 121 is formed on the entire wall of the tunnel portion 500 including the outer layer of the steel pipe 10 protruding toward the tunnel portion 500 for waterproofing.

[0093] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com