Ground solidifier composition using activated slag and pozzolanic reaction and manufacturing method thereof

A technology of soil curing agent and volcanic ash reaction, applied in chemical instruments and methods, building structures, fertilizer mixtures, etc., can solve problems such as dissolution, groundwater pollution, environmental pollution, etc., achieve high affinity, reduce alkalinity, and inhibit environmental pollution problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

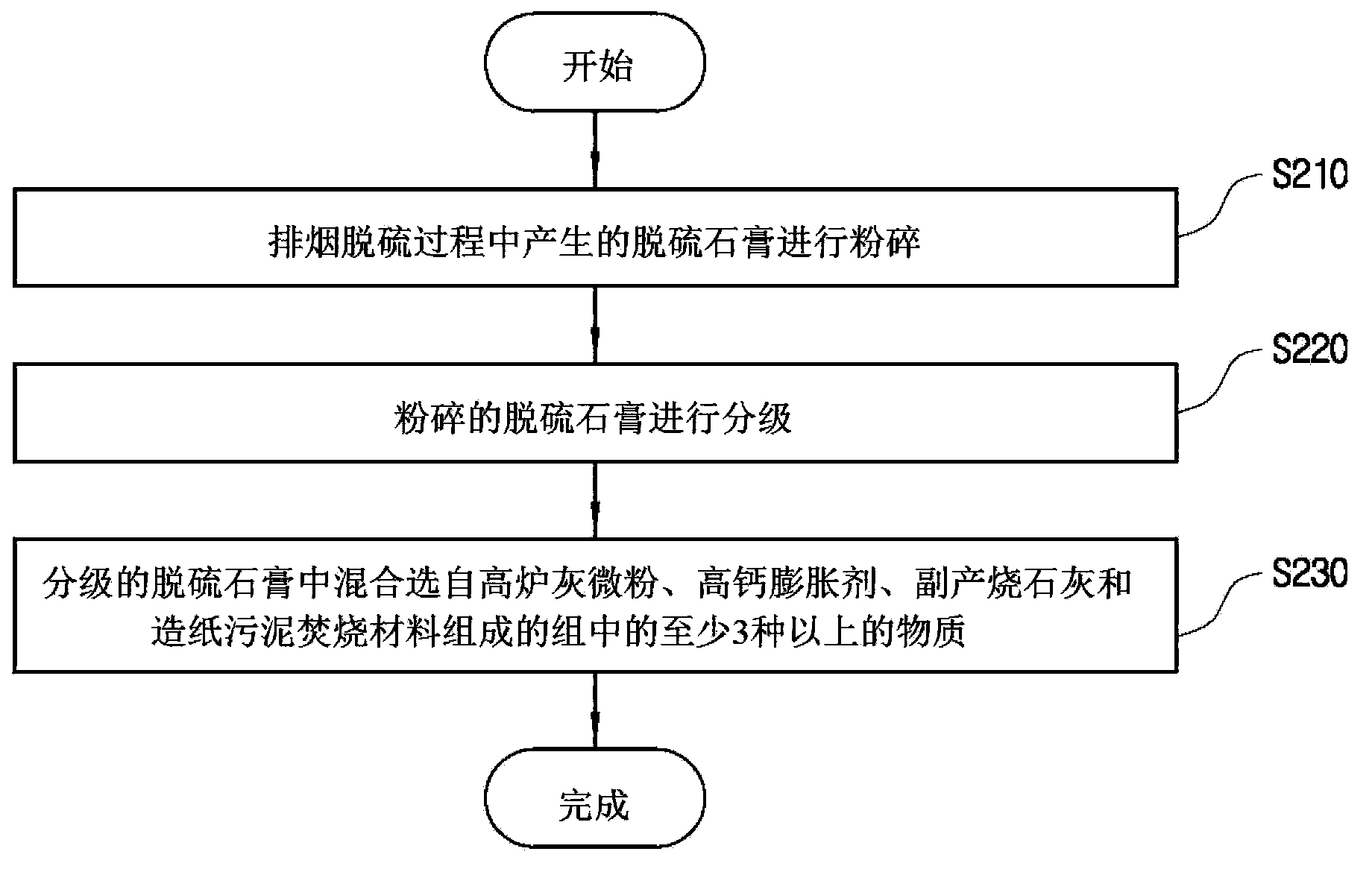

Method used

Image

Examples

Embodiment 1

[0042] First, the fineness of the powder produced during the production of pig iron in the iron factory is 4,000cm 2 45-65% by weight of blast furnace dust per gram or more, 5-30% by weight of desulfurized gypsum with a calcium oxide content of 50% by weight or more, sulfate content of 10% by weight or more, and fly ash with a calcium oxide content of 40% by weight or more 10-40% by weight of agent (high-calcium expansion agent), 1.5-10% by weight of by-product burnt lime with a calcium oxide content of more than 50% by weight, and uniformly mix to manufacture a soil stabilizer composition for soft subsoil improvement.

[0043] Using the thus-produced soil stabilizer for soft subsoil improvement, the sample soil with natural water content and the soil stabilizer for soft subsoil improvement were mixed, the amount of the soil stabilizer for soft subsoil improvement was 13% by weight, and the water / bonding agent was produced. 70% mixed soil.

[0044] Here, the sample soil with ...

Embodiment 2

[0049] According to the method of embodiment 1, the difference is that the amount of soil curing agent for soft subsoil improvement is 14% by weight, and the water / binding agent ratio is 70% for the mixed soil.

Embodiment 3

[0051] According to the method of embodiment 1, the difference is that the amount of soil curing agent for soft subsoil improvement is 16% by weight, and the water / binding agent ratio is 70% for the mixed soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com