Plain-barreled roll rhomboidity rolling method

A flat roll and square off technology, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of pouring steel, flat roll rolling technology widely popularized and used restrictions, rolled pieces skew, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

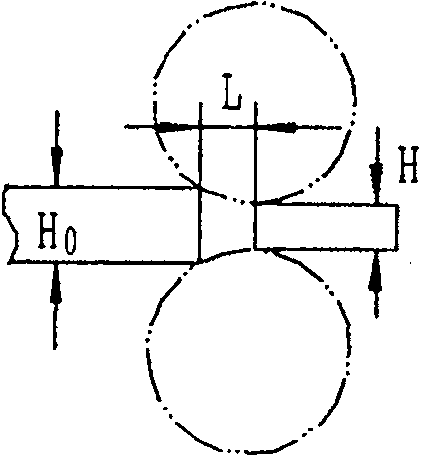

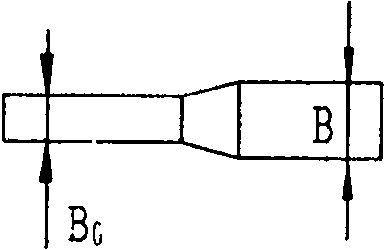

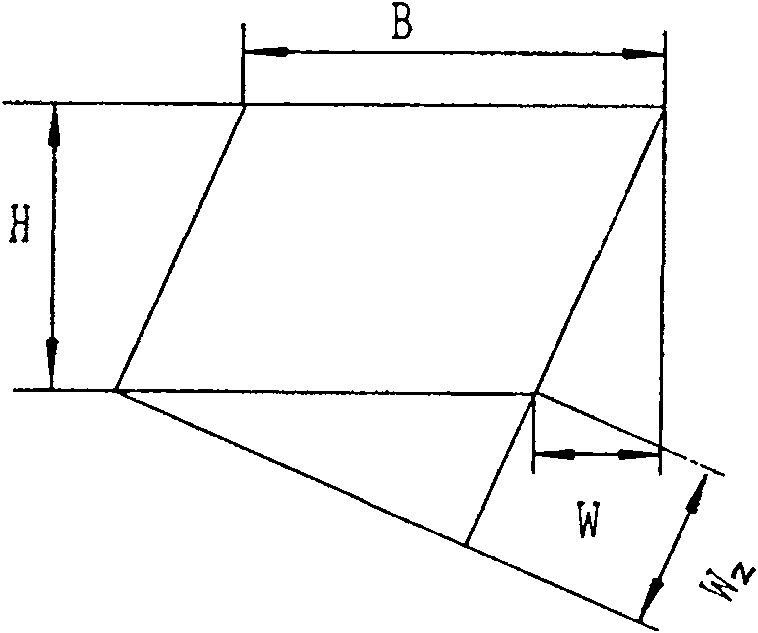

[0024] The method of the present invention is made up of two steps of flat roll off-square rolling and diamond-square pass rolling. In the flat roll off-square rolling step, the off-square amount of the rolled piece produced in flat roll rolling is utilized and controlled. After the first rolling, flat rolls are used to roll out a diamond-shaped cross-section rolling piece, and then enter a few rhombus-square hole rolling to produce a square-section rolling piece. The method uses continuous casting slabs with square cross-sections as raw materials, and can be implemented on continuous rolling mills and transverse rolling mills for rolling square steel or as rough rolling for rods and wires. see Figure 7 , which is a schematic diagram of rolls that have undergone 4 passes of flat roll off-square rolling and 3 passes of diamond-square pass rolling on a tandem rolling mill.

[0025] The core technology of the present invention is to accurately control the amount of stripping of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com