Automatic combined raking filling machine for loose material

A technology of rake loading and material, applied in glass production and other directions, can solve the problems of uneven blending, large manpower and material resources, affecting the quality of glass products, etc., and achieve the effect of improving production efficiency, high degree of mechanization, and improving the quality of glass products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

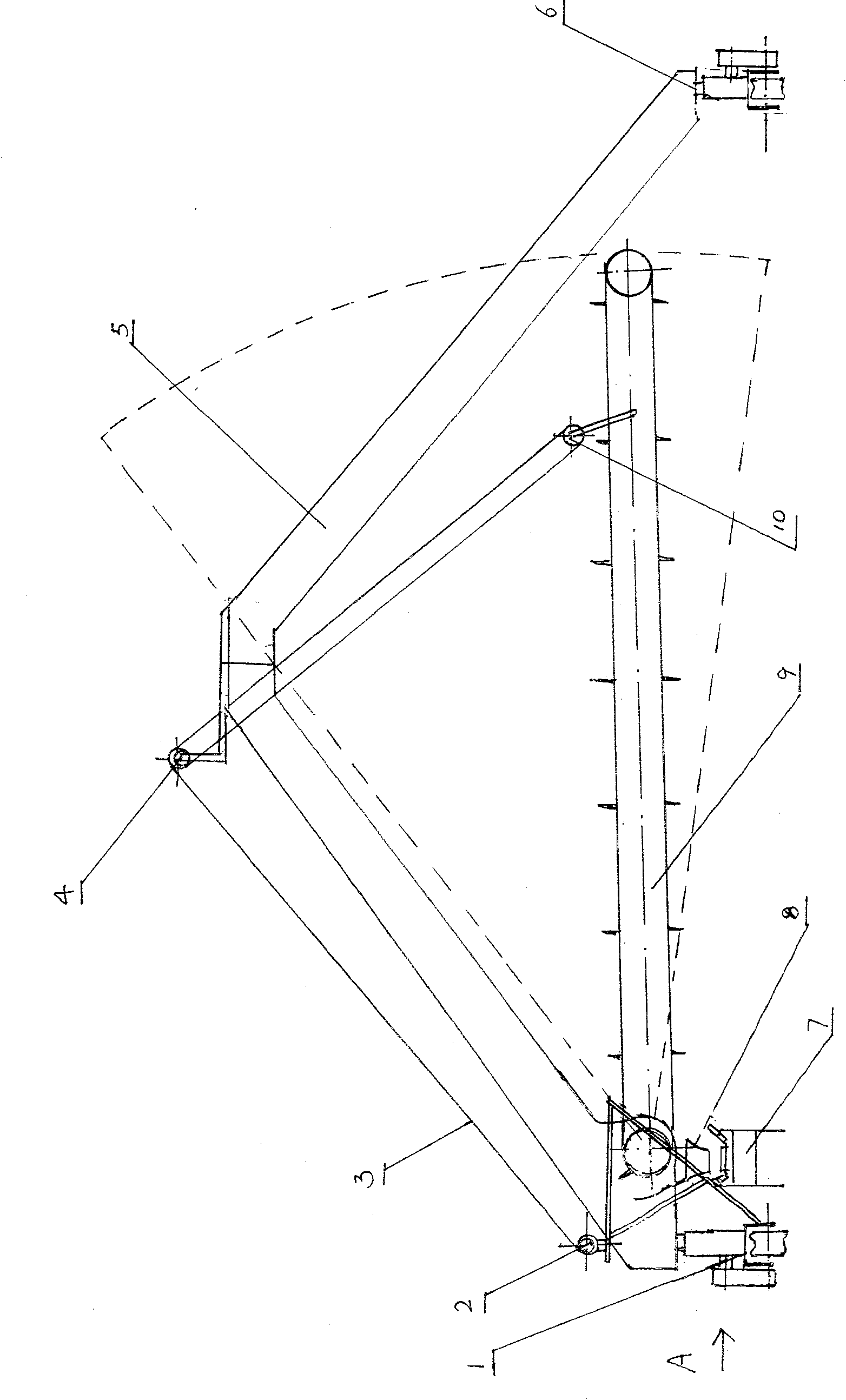

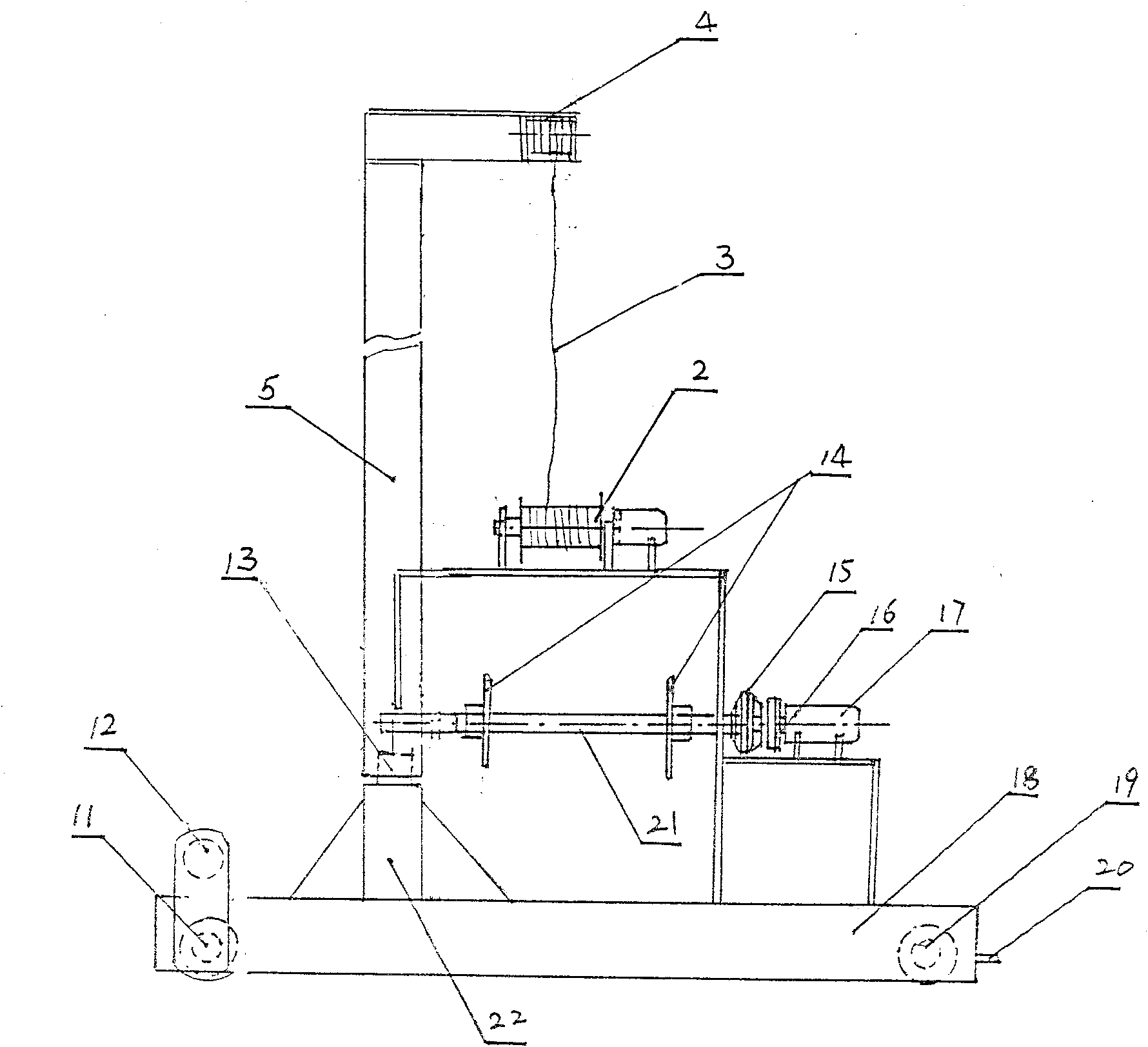

[0015] Now according to figure 1 The main structure of the embodiment will be described.

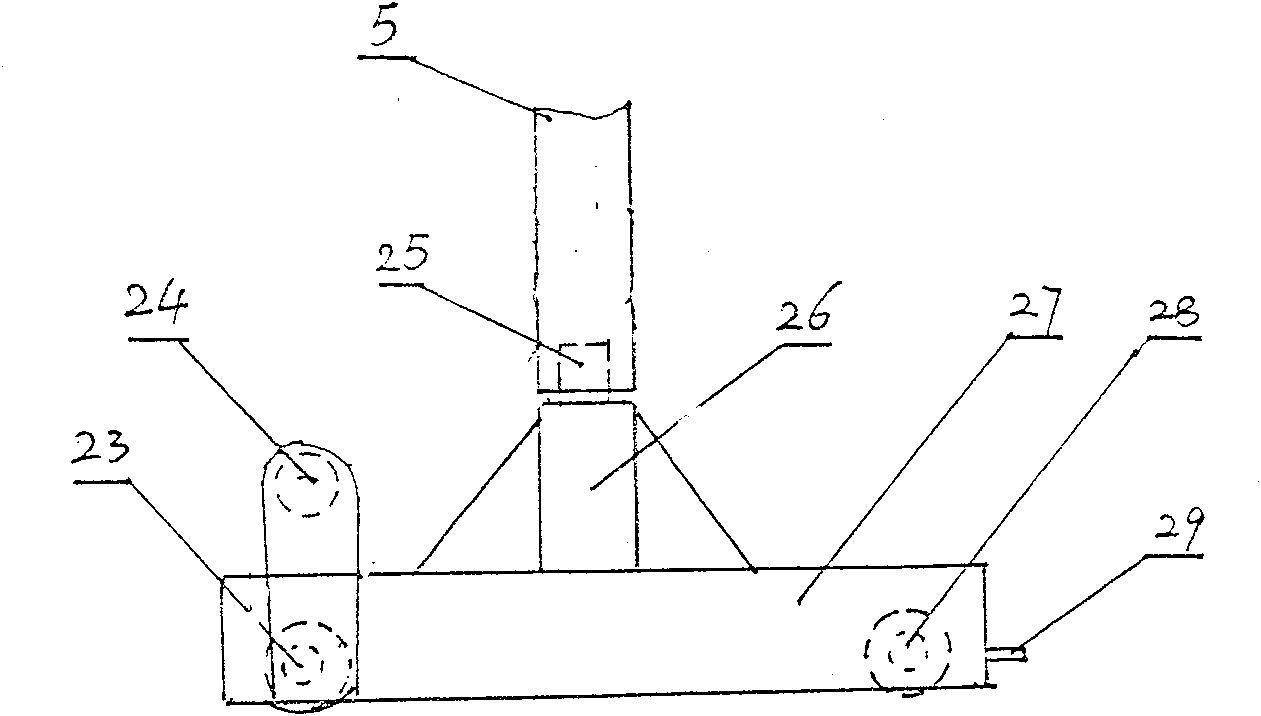

[0016] On the double rails laid on both sides of the sand in the storage plant (the double rails are laid along the direction of the belt conveyor 7), the rail-wheel type walking arch is installed and arranged, which connects the two legs of the herringbone arch structure 5 to the rails on both sides. on the base; the base is divided into main seat 1 and auxiliary seat 6. From figure 2 , image 3 It can also be seen that there is a column frame 22 with a rotating shaft 13 on the main seat 1, and a column frame 26 with a rotating shaft 25 on the auxiliary seat 6, which is movably connected with the arch structure through the rotating shafts of the main and auxiliary seats, and the arch structure is square. Steel pipes are welded.

[0017] A sprocket rake arm 9 and an electric hoist 2 are installed on the main base 1. A pulley block 4 is arranged on the top of the arch structure 5. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com