Multi-layer film synchronous production system and method

A production system and multi-layer film technology, applied in the chemical industry, can solve problems such as reducing production efficiency, increasing equipment costs, and deteriorating product quality, and achieving the effect of ensuring quality and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For the technical features of the present application, the purpose and effect more clearly understood, reference now be described the control of specific embodiments of the present application. Wherein the same parts are designated by the same reference numerals.

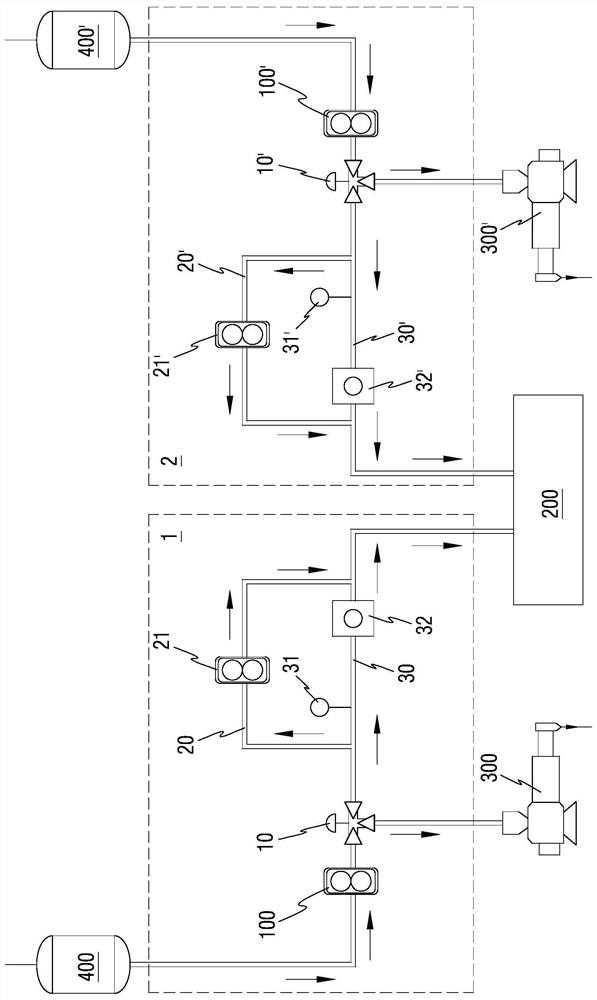

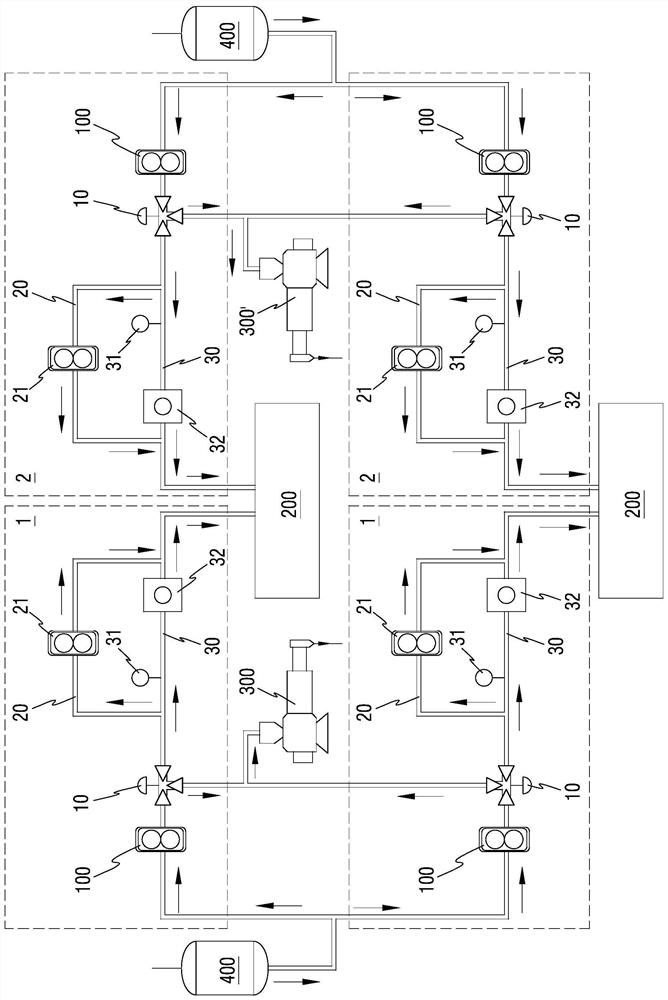

[0022] The present application provides a figure 1 Synchronization multilayer film production system shown, the multilayer film production system can be used to synchronize multiple polymer melt continuously fed to the multi-layer film manufacturing apparatus to prepare a thin-film multilayer structure, the polymer including but not limited to, polyethylene, polyvinyl chloride, polystyrene, polyester films, polypropylene, nylon, and other thermoplastic polymers.

[0023] As shown, the multilayer film of the present application provides synchronization of the production system comprising at least a first conveying device by first preparing a first melt of a first mold A and a layer B was prepared by melt second la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com