Regulation structure of chain saw chain

A technology for adjusting the structure and chain, which is applied in the field of chain saws. It can solve the problems of blunt chains, easy contact with blades, and short adjustment strokes. It achieves the effects of convenient installation of guide plates, increased safety, and large adjustment strokes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

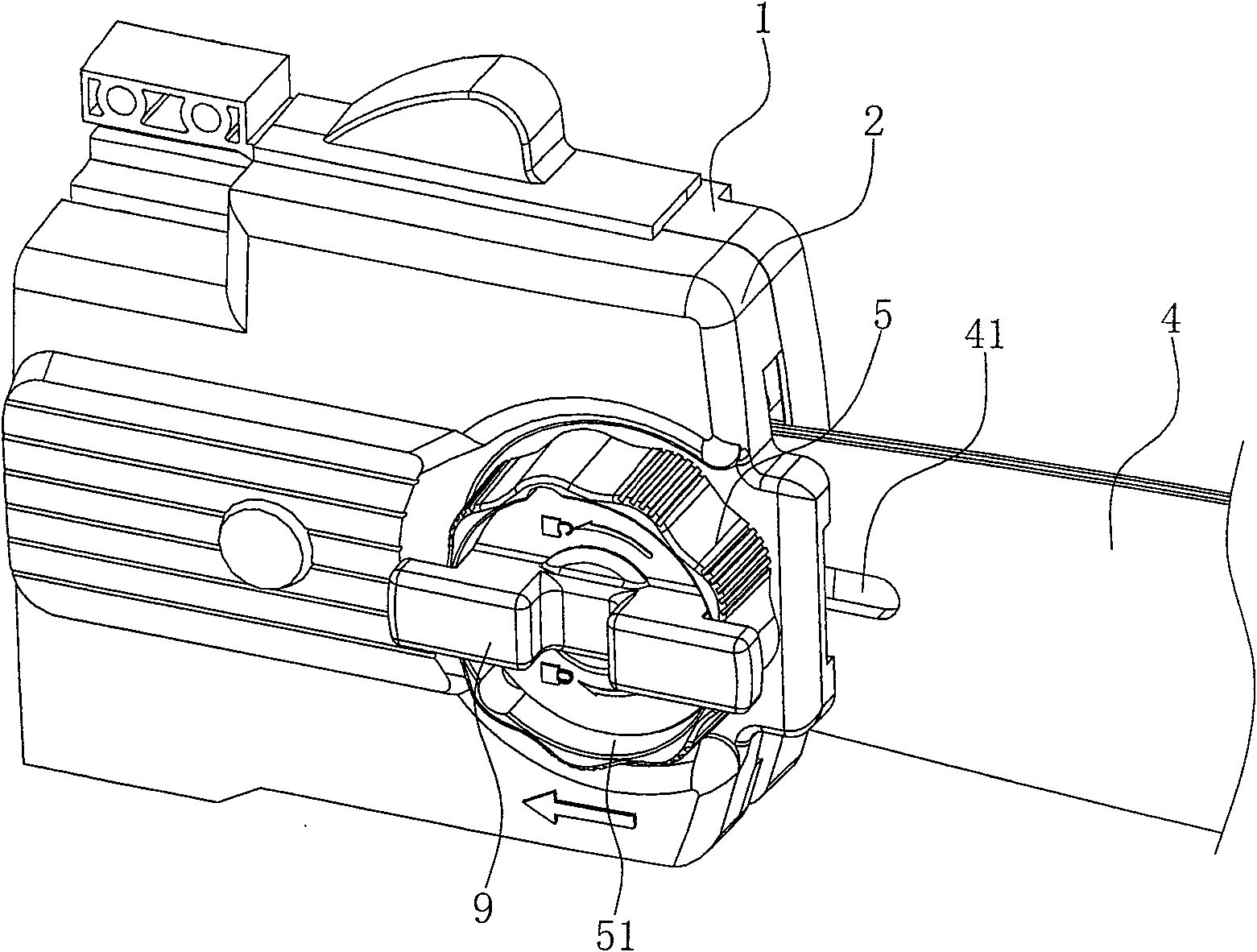

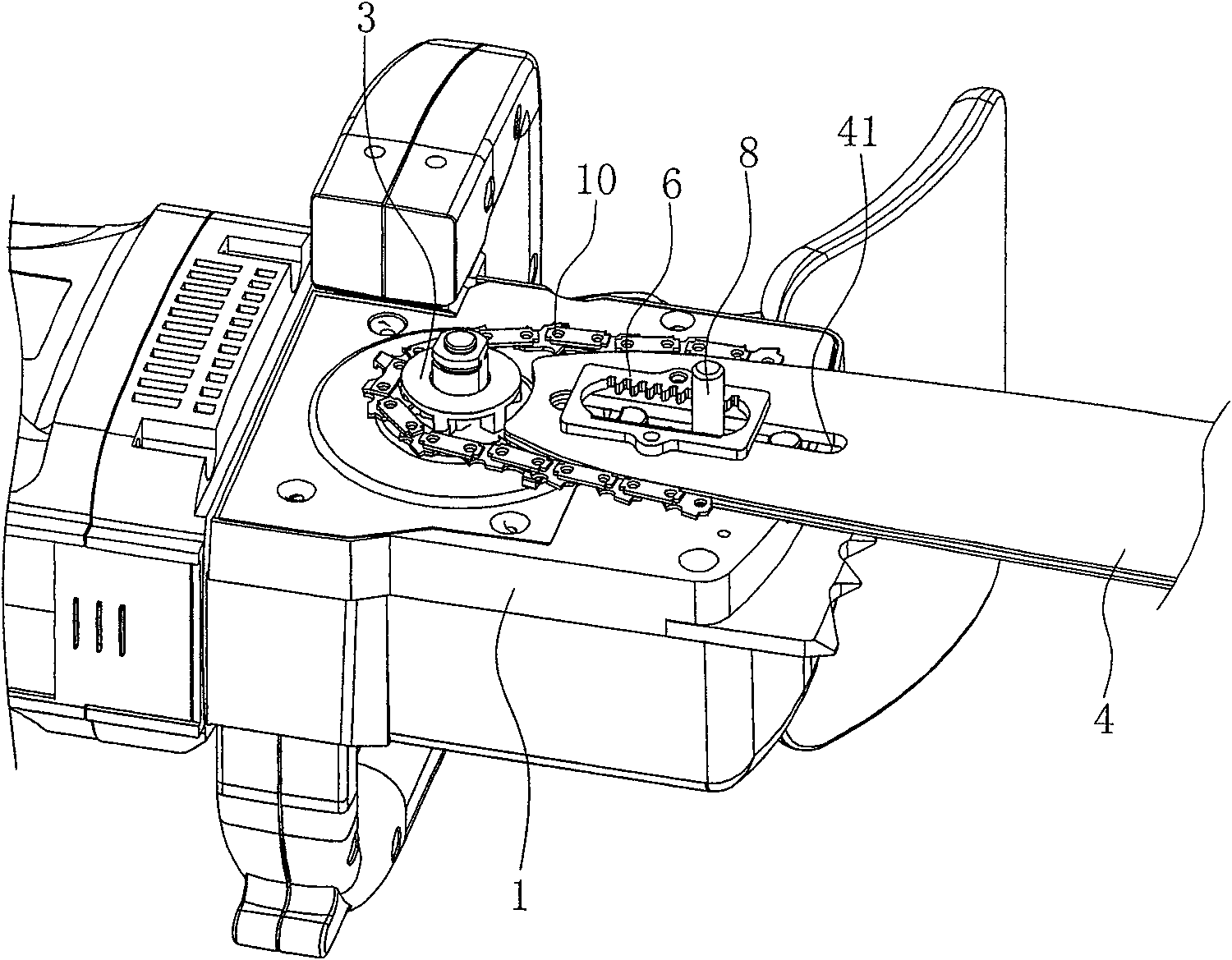

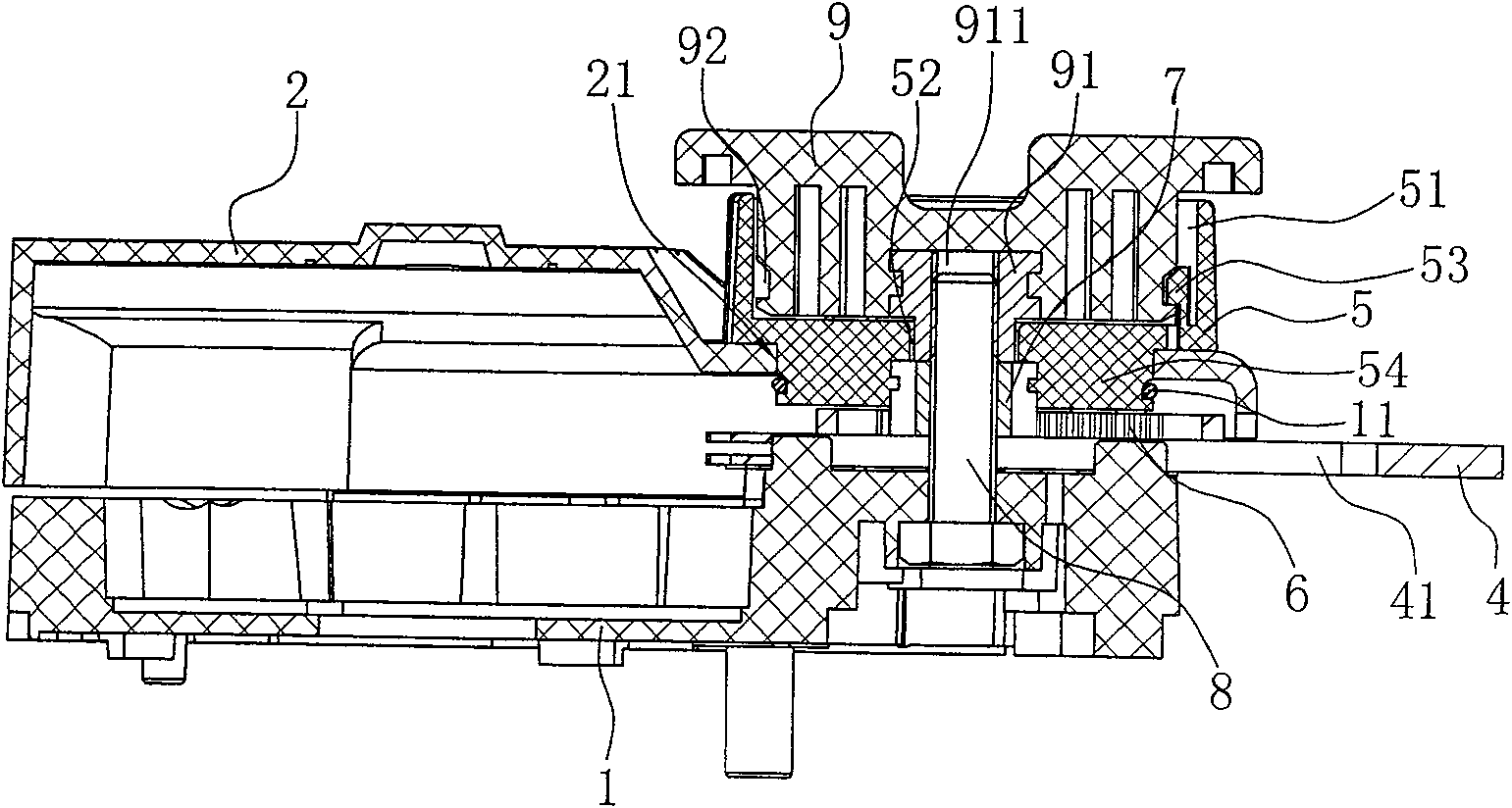

[0032] like Figure 1~4 Shown is a preferred embodiment of the utility model.

[0033] An adjustment structure for a chain saw chain, comprising a sprocket base 1, a cover plate 2 fixed on the sprocket base 1, the sprocket base 1 and the cover plate 2 are assembled and fixed to form a complete box, and the sprocket base 1 A sprocket 3 is installed on one side, and the sprocket 3 is driven to rotate by a motor. An upwardly protruding bolt 8 is fixed on the other side of the sprocket seat 1, and a guide plate whose outer end protrudes from the sprocket seat 1 is also provided on the sprocket seat 1. 4. The chain 10 is guided circularly along the edge of the guide plate 4 and suspended on the sprocket 3. The middle part of the inner end of the guide plate 4 has a transverse through groove 41, and the bolt 8 moves through the through groove 41, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com