Braking device for garden tools

A brake device and garden tool technology, which is applied in the direction of brake types, drum brakes, couplings and brakes, etc., can solve the problems of high parts processing requirements, large number of parts, and high production costs, and achieve good results. Braking function, reduced production cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

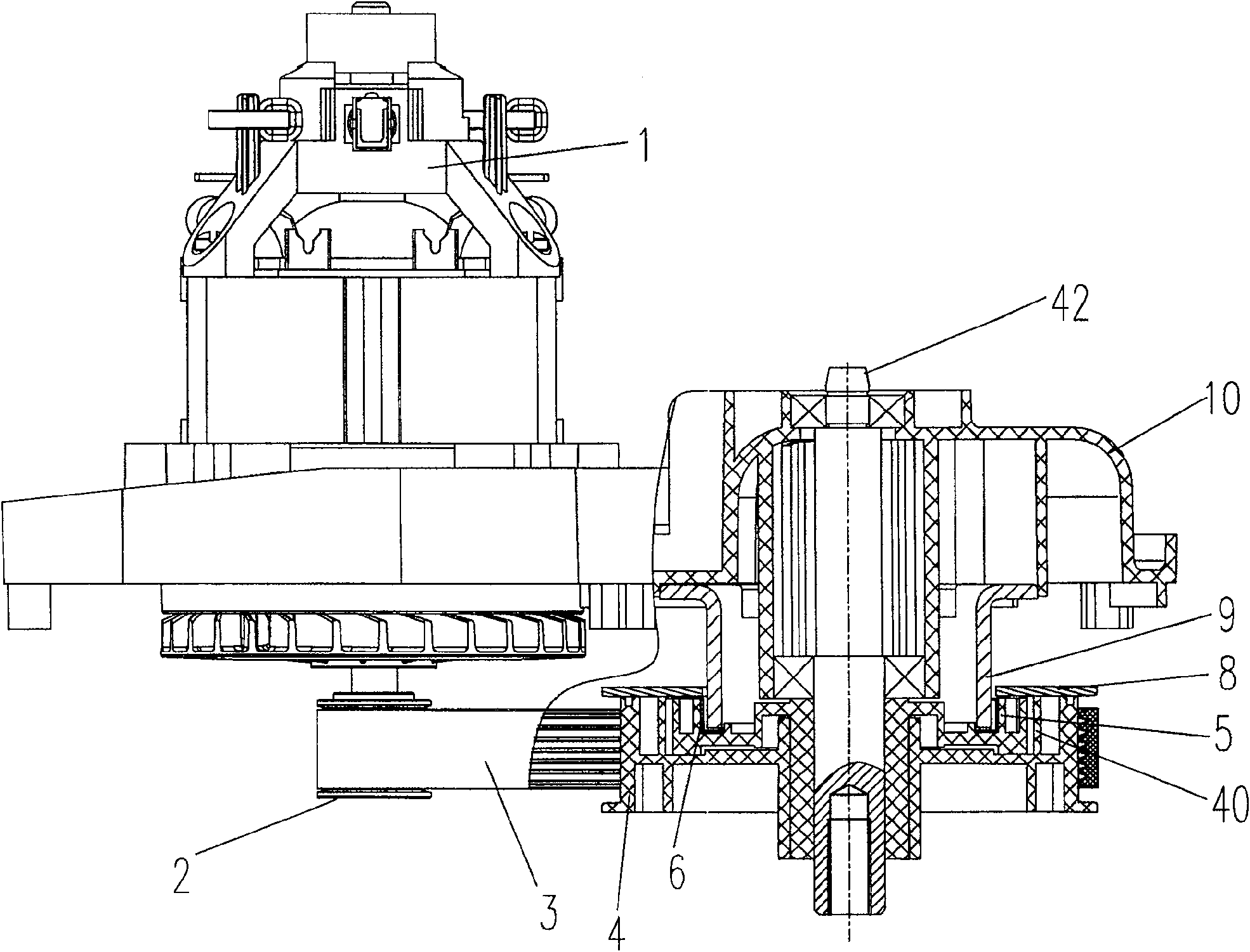

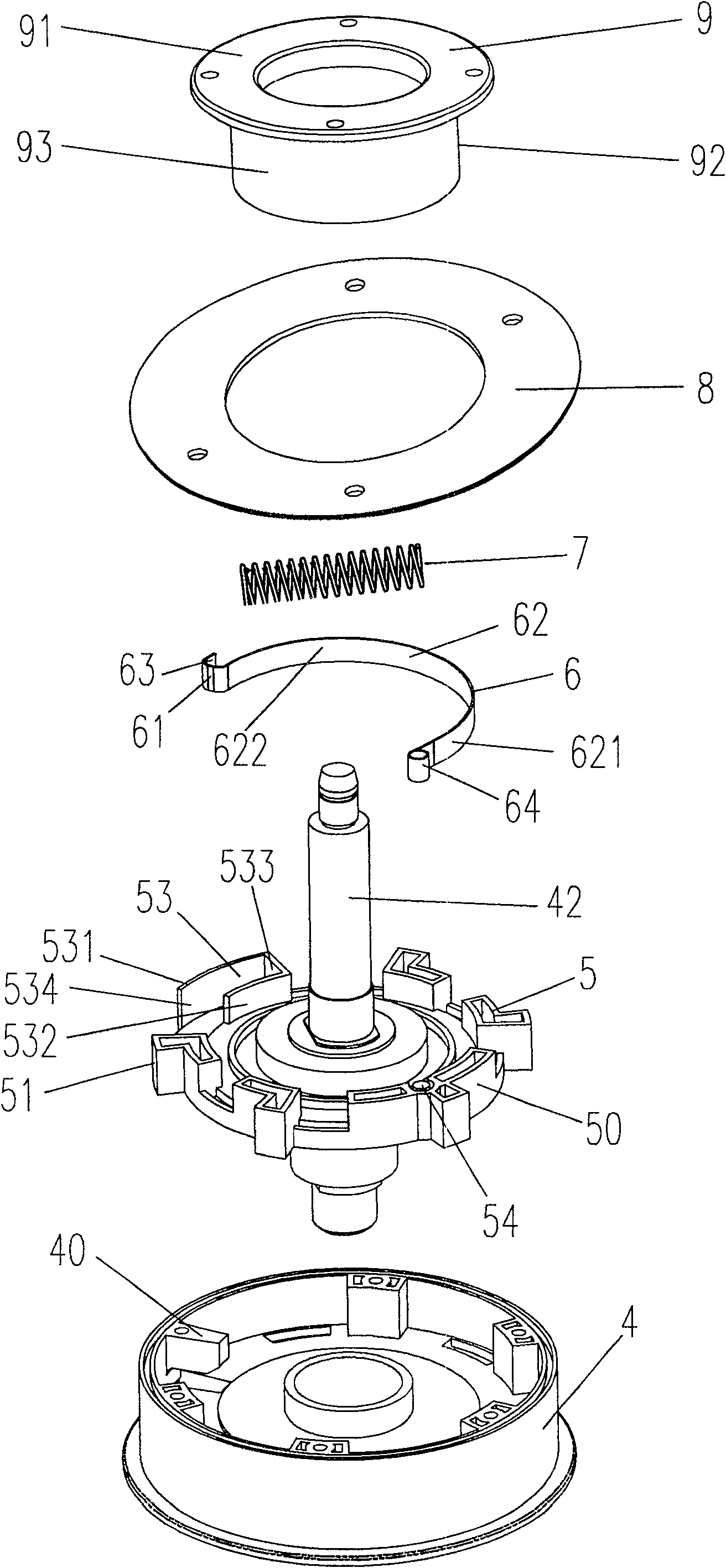

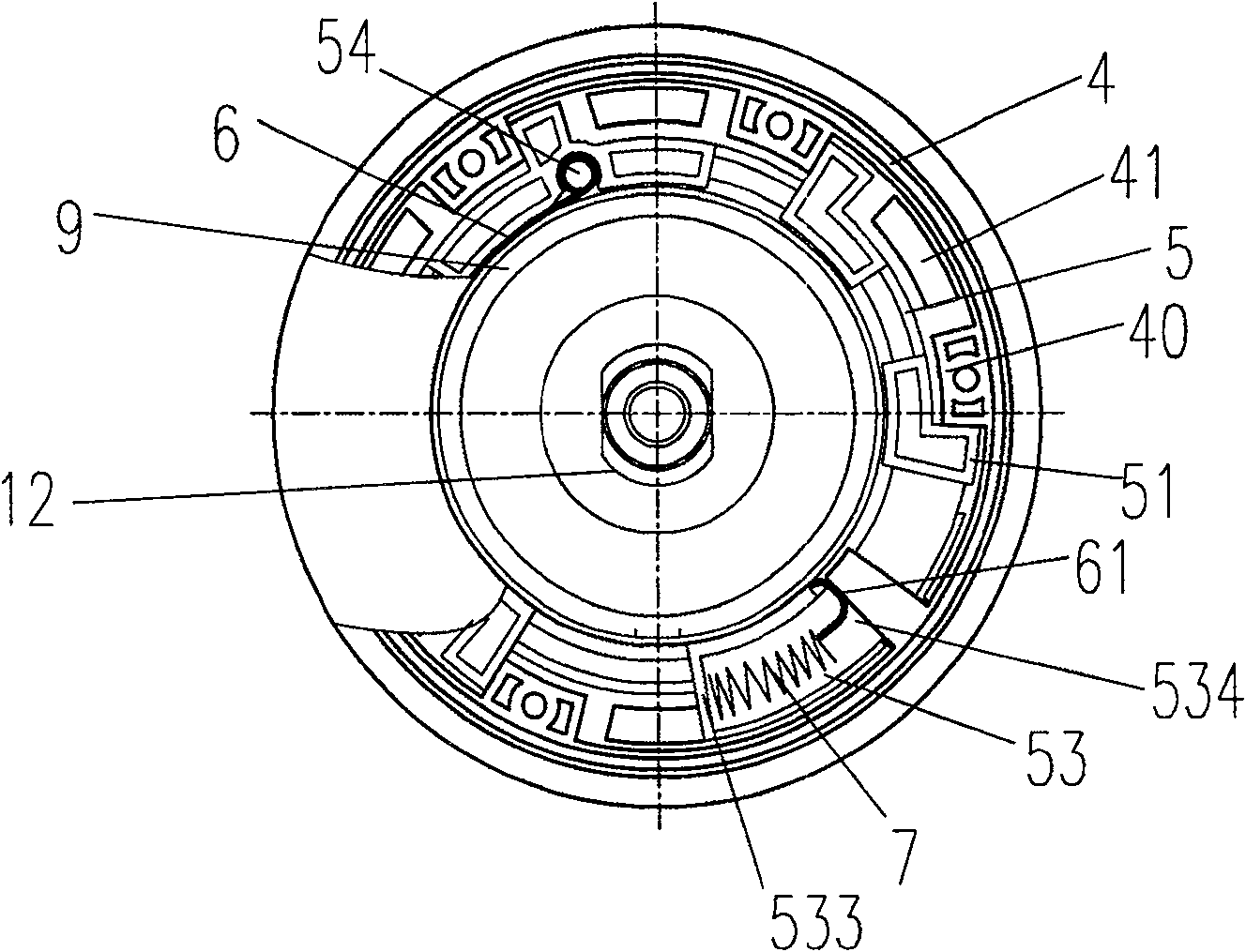

[0015] The structure of this embodiment is as Figure 1 to Figure 3 Shown, garden tool of the present invention is used braking device, and wherein garden tool comprises motor 1, driving wheel 2, belt 3 and the working shaft 42 that is used to install cutter, braking device is made of the working wheel assembly that rotates around working shaft 42 and system Composition of moving elements. The working wheel assembly is composed of an inner wheel 5 fixedly connected to the working shaft 42 and an outer wheel 4 sleeved outside the inner wheel 5 , and the belt 3 is wound on the outer wall of the outer wheel 4 . Wherein, a plurality of protrusions 40 are arranged on the inner wall of the outer wheel 4, and the protrusions 40 extend from the inner wall to the center. On the outer wall surface 50 of the inner wheel 5 , a plurality of protrusions 51 corresponding to the protrusions 40 of the outer wheel 4 are provided, and the protrusions 51 protrude outward from the outer wall surf...

Embodiment 2

[0019] see Figures 4 to 6 , In the present embodiment, the outer wheel 4' includes an outer wall 41' and an inner wall 45', wherein a plurality of protrusions 40' are arranged on the inner side of the outer wall 41', and the protrusions 40' extend from the inner side to the center. And the outer wall surface 50' of the inner wheel 5' is provided with some protrusions 51' corresponding to the projections 40' of the outer wheel 4', and the protrusions 51' protrude outwards from the outer wall surface 50'. When the outer wheel 4' is assembled with the inner wheel 5' and the working wheel assembly rotates normally, the protrusion 40' of each outer wheel 4' abuts against the protrusion 51' of each inner wheel 5', thereby driving the inner wheel 5 'rotate around the working axis 42'.

[0020] The braking element is composed of a first braking element 6', a second braking element 9' and an elastic element 7'. A receiving groove 43' is provided between the outer wall 41' and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com