Electronic ballast of high strength gas discharging light

A technology for electronic ballasts and gas discharge lamps, applied in the use of gas discharge lamps, electric light sources, electrical components, etc., can solve the problems of many components, high cost, complex structure, etc., achieve high power factor, enhance stability to ensure the effect of output light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

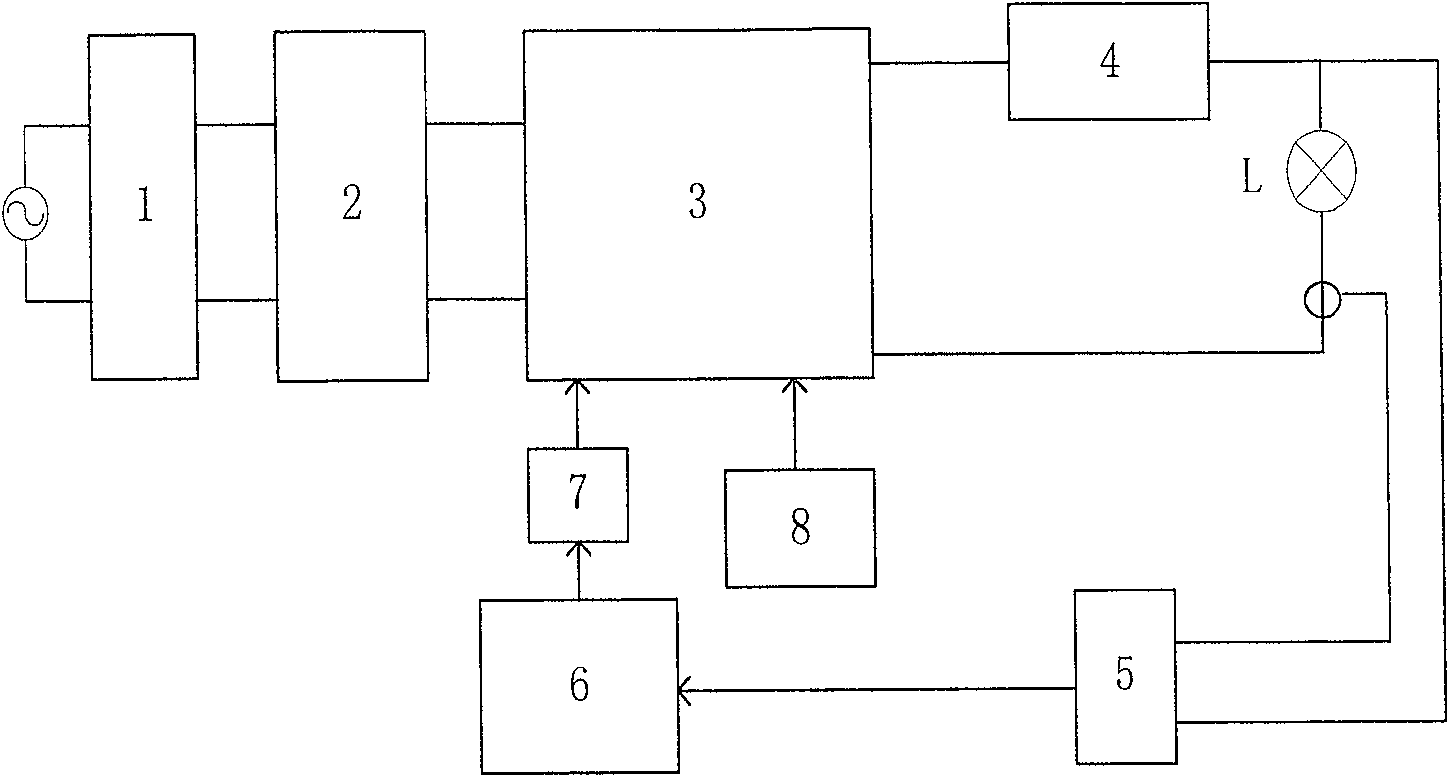

[0020] refer to figure 1 , the high-intensity gas discharge lamp electronic ballast of the present invention includes an electromagnetic interference filter circuit 1, a rectifier bridge 2, a combined single-stage power factor correction and a low-frequency square wave signal generating circuit 3, a high-intensity gas discharge lamp L, and a lamp L provides ignition circuit 4 for high-voltage pulse signal, voltage and current detection circuit 5, constant power control circuit 6, high-frequency switch tube drive circuit 7 and low-frequency drive signal generator 8. The voltage and current signals detected from the lamp L are input to the constant power control circuit 6 after passing through the voltage and current detection circuit 5, and the pulse width of the output drive signal is modulated by the constant power control circuit 6, so that the power output to the lamp L is basically constant .

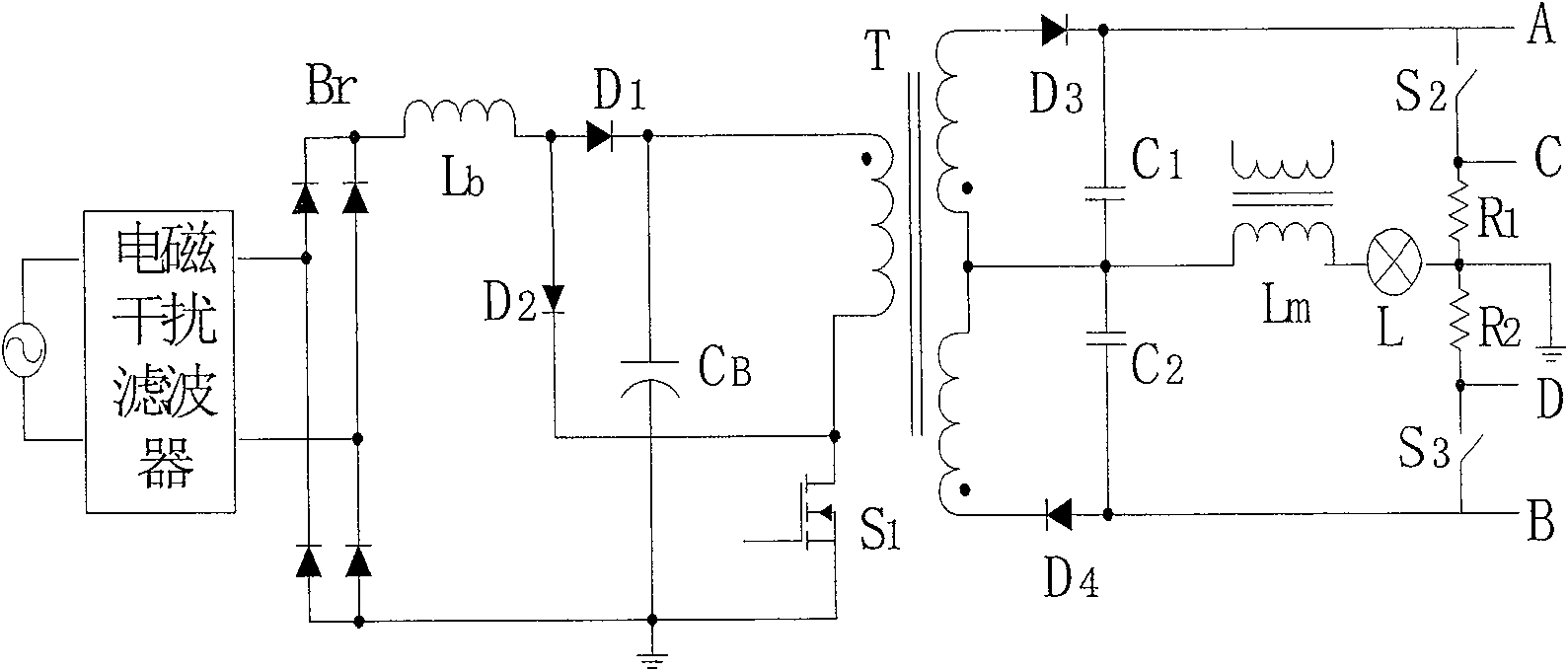

[0021] figure 2 Shown is a circuit example of a combined single-stage power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com