Shaft sealing mechanism and turbine

A shaft seal, thin plate technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of thin plate wear and heat, and achieve the effect of preventing heat generation, preventing wear and improving air pressure distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

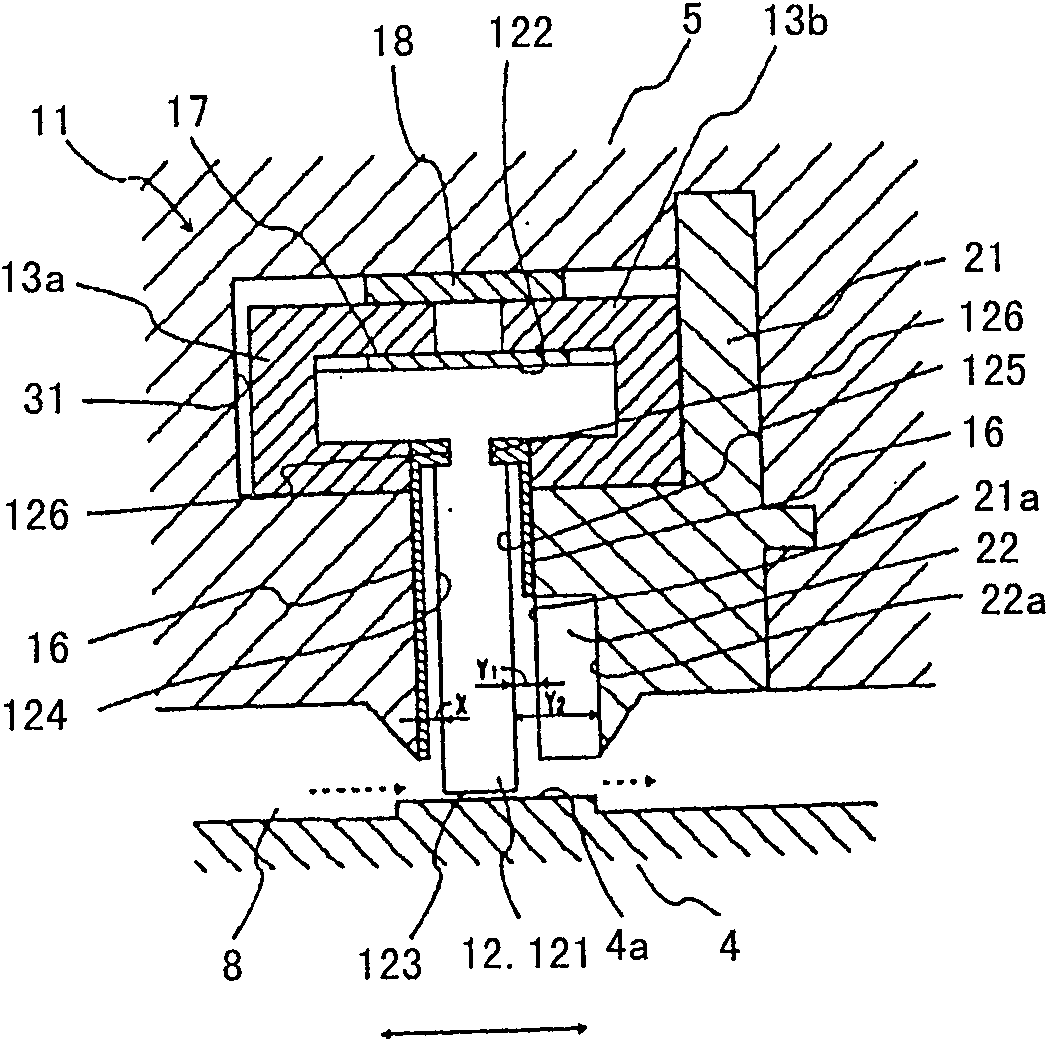

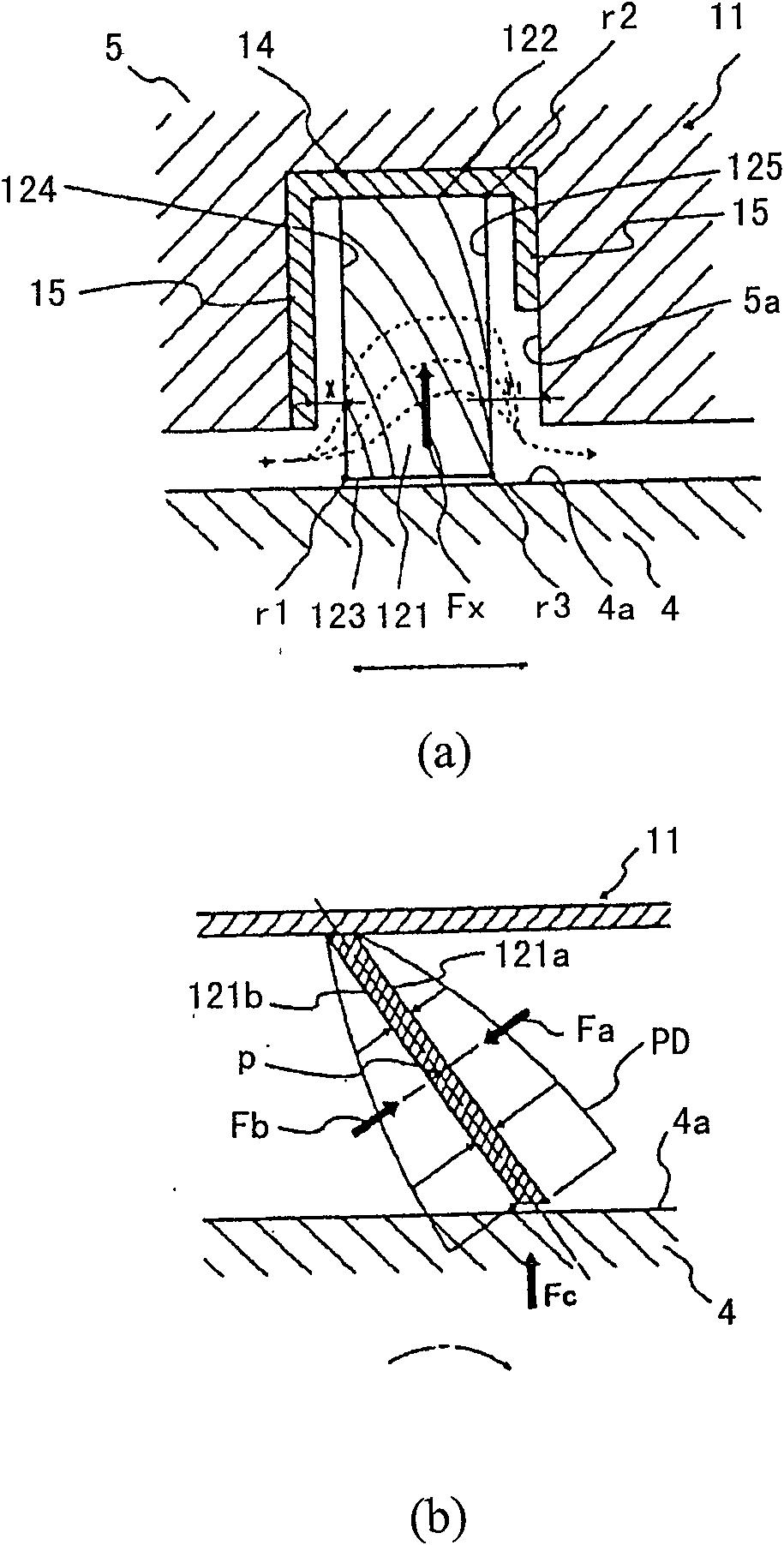

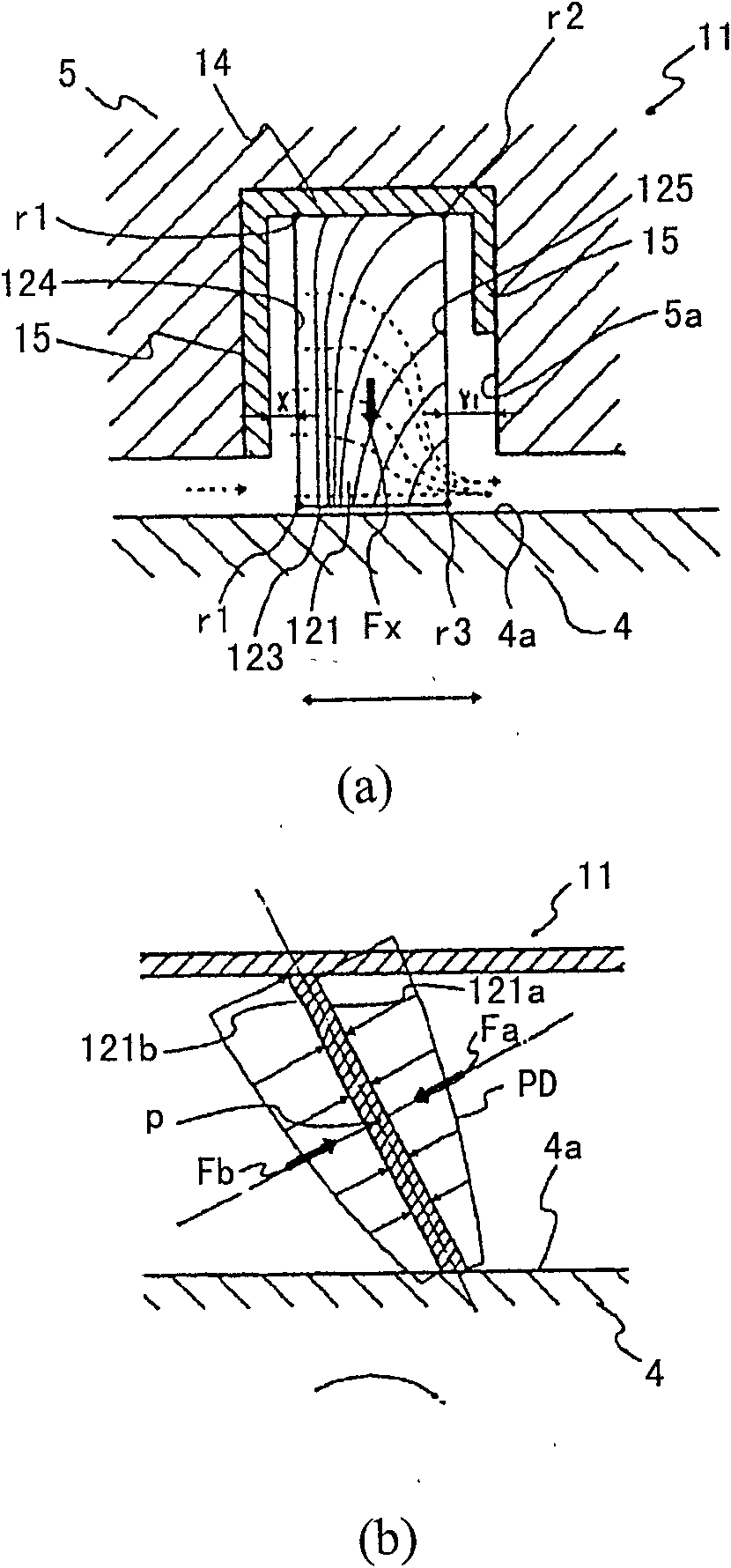

[0039] Embodiments of the shaft seal mechanism and the structure for mounting the shaft seal mechanism to the stator according to the present invention will be described below with reference to the drawings. However, these are merely examples of the embodiment, and are not limited to the examples as long as they have the functions and structures of the shaft seal mechanism that are characteristic of the present invention. In addition, although the present embodiment has been described using a gas turbine as an example, it can also be applied to a steam turbine.

[0040] First, as the first embodiment, regarding a shaft seal mechanism composed of a sheet seal having one split portion (referred to as a split-type sheet seal) and a structure for attaching the shaft seal mechanism to a stator, refer to figure 1 Be explained.

[0041] figure 1 It shows a shaft seal mechanism composed of sheet seals and a structure in which the shaft seal mechanism is attached to a stator viewed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com