Analytical control system for drying pod

A control system and cocoon technology, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems affecting clarity and silk quality, poor precision, large one-time investment, etc., to improve clarity And silk, improve the drying accuracy, the effect of reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: In East China, the Suju×Minghu variety was dried in autumn. Its top drying data are shown in Table 1:

[0052] Table 1

[0053]

[0054] Its two baking data are as shown in table 2:

[0055] Table 2

[0056]

Embodiment 2

[0057] Example 2: in East China, the Suzhen×Chunguang variety was dried in spring. Its top drying data are shown in Table 1:

[0058] Table 1

[0059]

[0060] Its two baking data are as shown in table 2:

[0061] Table 2

[0062]

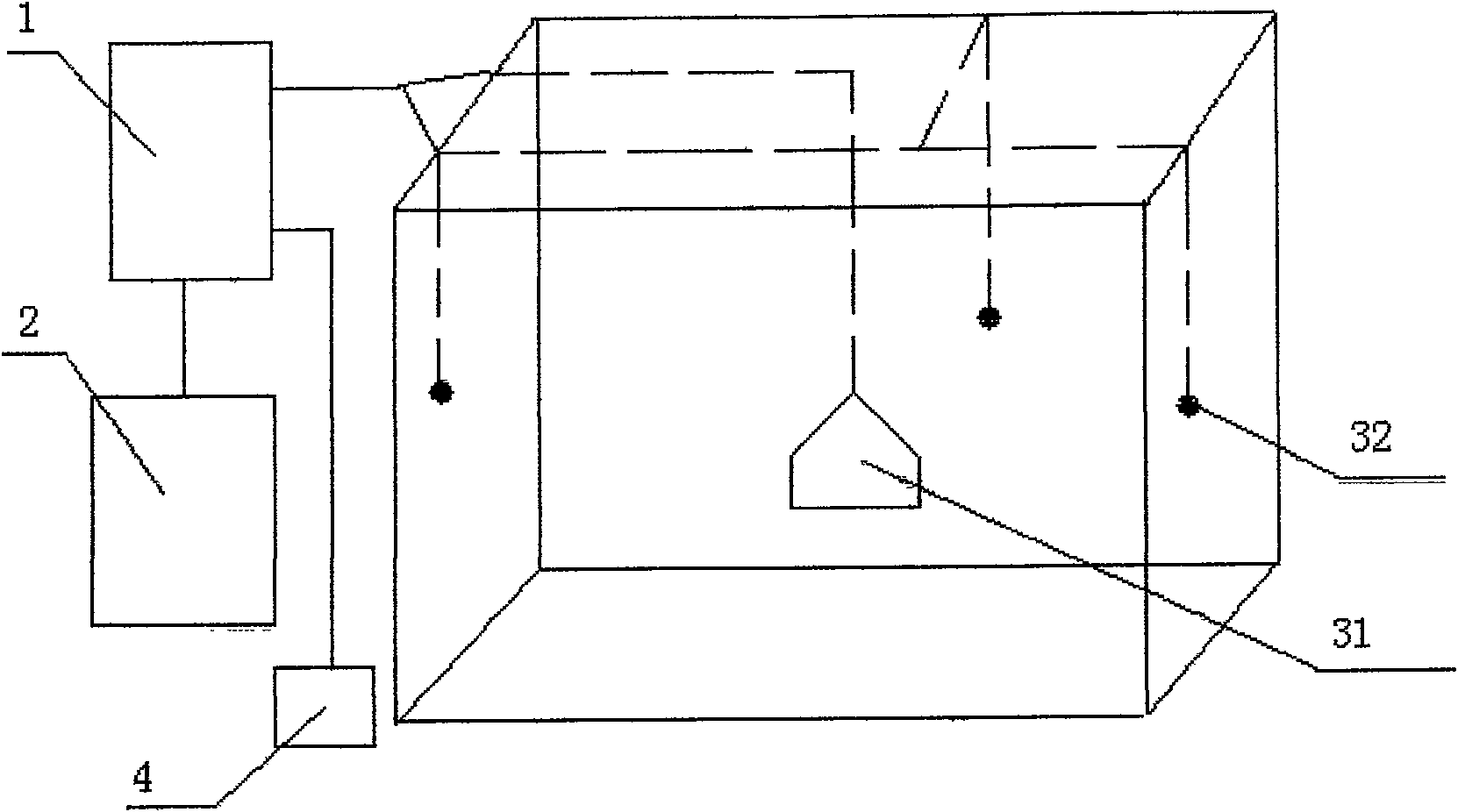

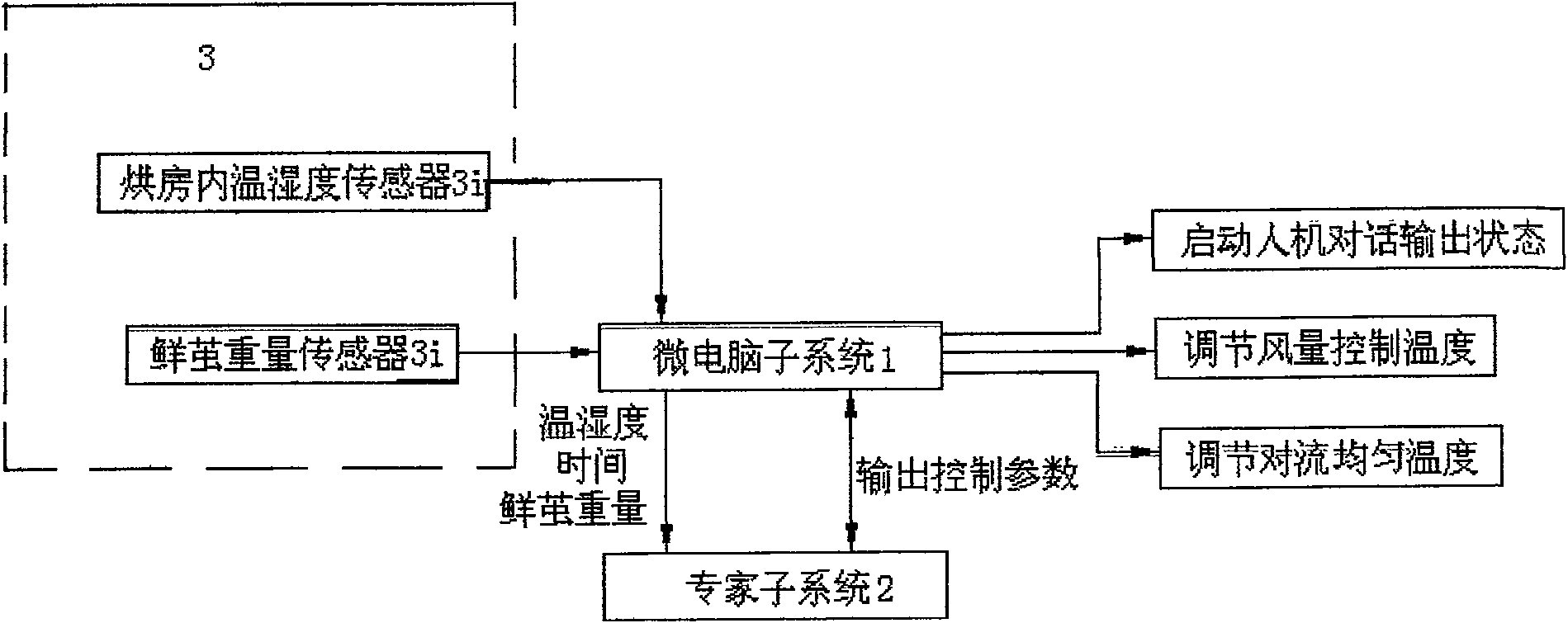

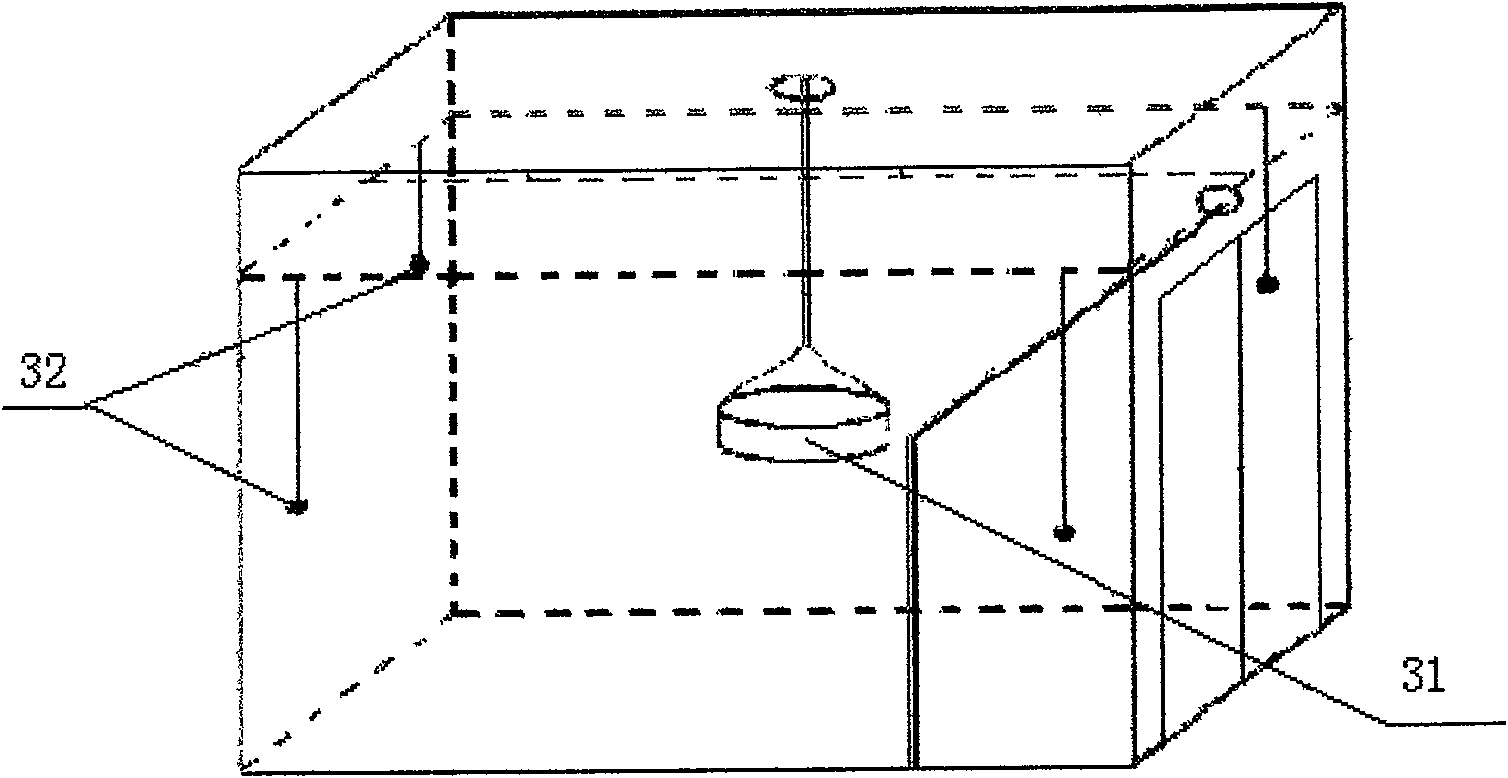

[0063] First, the drying data of different varieties, different seasons, and different weather conditions are input into the expert subsystem 2. During the drying process, the drying data is monitored by the microcomputer subsystem 1, and in the drying process The comparison and correction can be carried out at any time, which improves the drying efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com