High speed shearing grinder for modified bitumen

A modified asphalt, high-speed shearing technology, applied in grain processing and other directions, can solve problems such as unstable product ductility index, achieve significant benefits and effects, increase output, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation

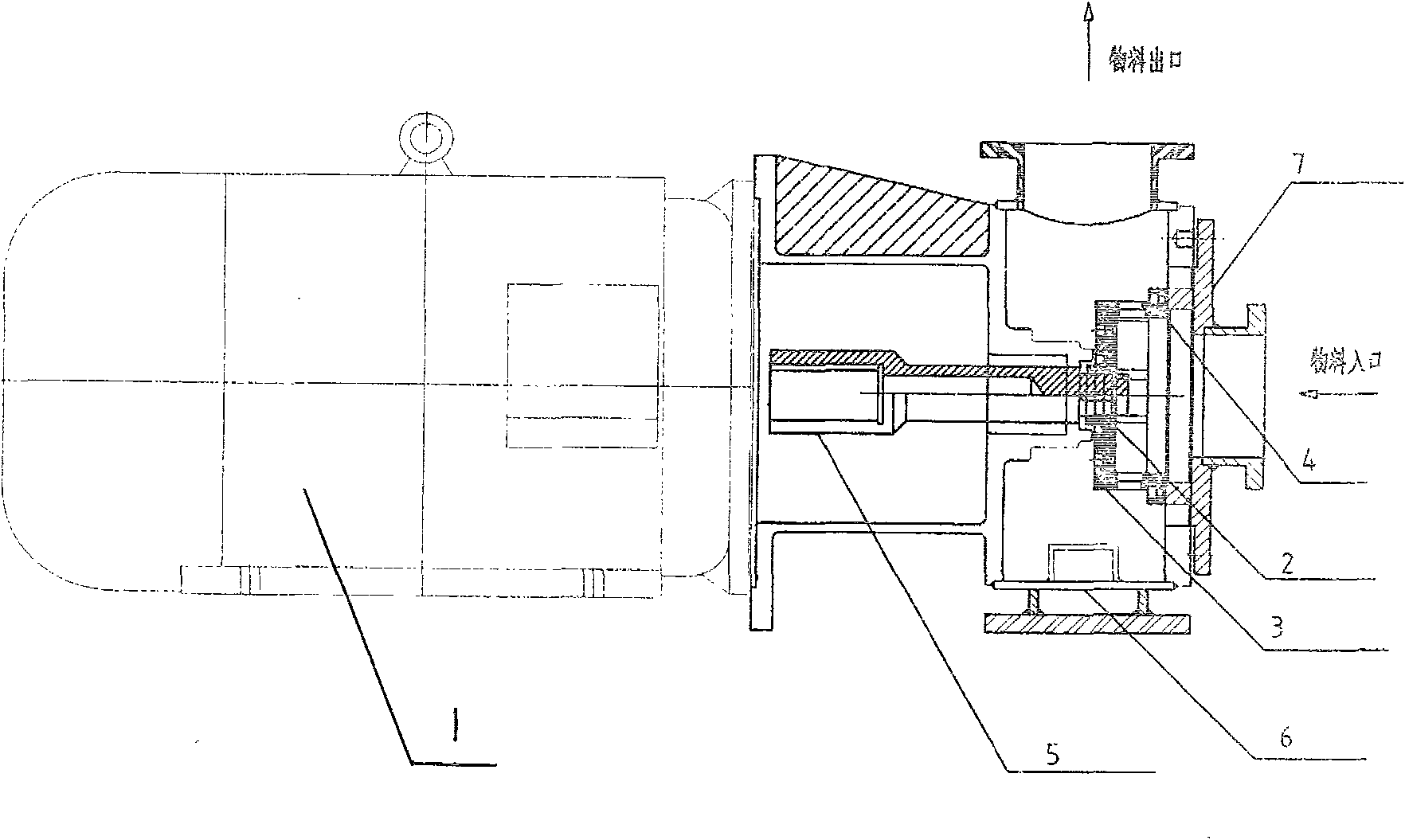

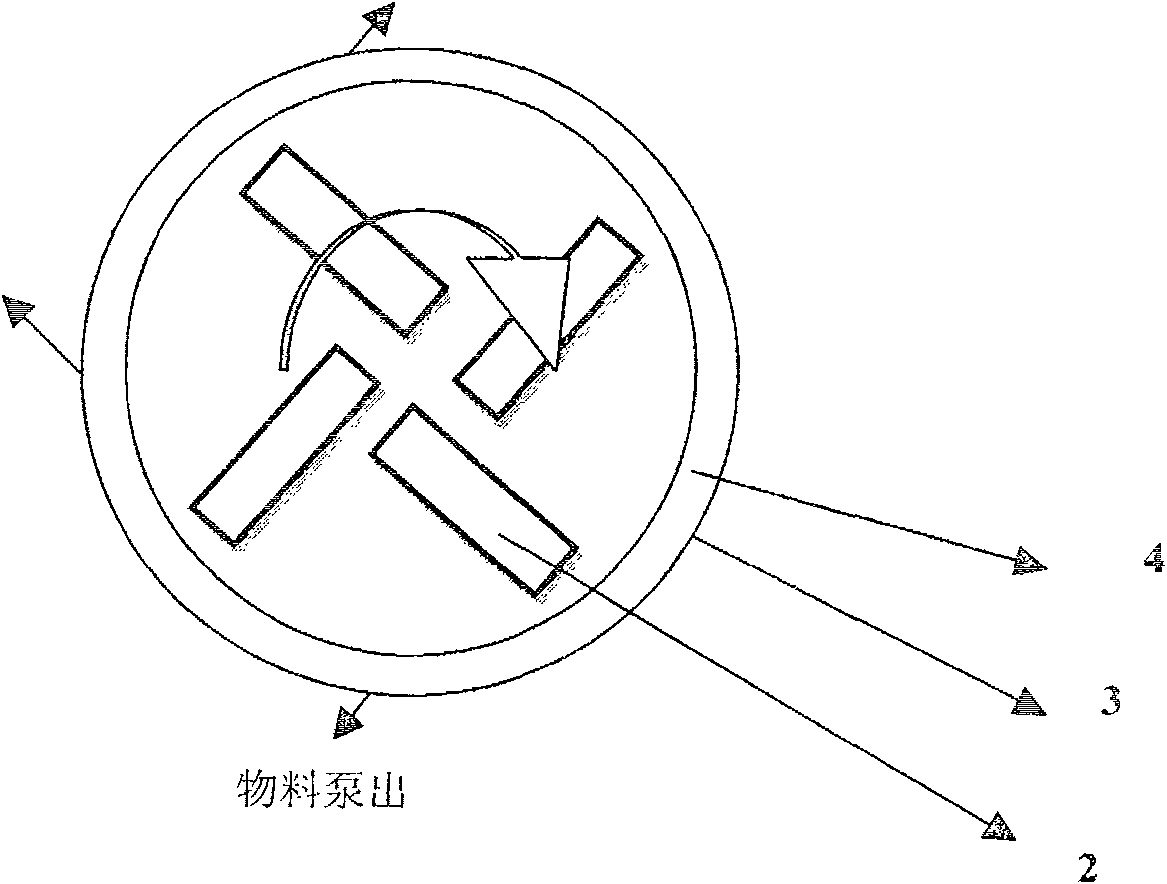

[0012] figure 1 Instructions marked in: 1-high-speed motor; 2-centrifugal self-priming blade; 3-moving cutting ring; 4-static cutting ring, 5-connecting shaft, 6 pump casing, 7-connecting flange, 8-static knife hole , 9-moving knife hole.

[0013] The modified asphalt high-speed shear mill of the embodiment of the present invention comprises a high-speed motor 1, a dynamic cutting ring 3, a static cutting ring 4 and a pump casing 6, the dynamic cutting ring 3 is connected to the high-speed motor connecting shaft 5, and the static cutting The ring 4 is installed on the pump casing 6, and the pump casing 6 has a feed port and a discharge port. It is characterized in that: the centrifugal self-priming blade 2 is also connected to the high-speed motor connecting shaft 5, and the periphery of the centrifugal self-priming blade 2 The positions are followed by the static knife hole 8 of the static cutting ring 4 and the moving knife hole 9 of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com