Self-resetting beam-grid friction wall structure system

A self-reset, grid technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor deformation capacity and energy dissipation capacity, low bearing capacity, poor ductility, etc., to achieve strong energy dissipation capacity and simple structure. , the effect of easy components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

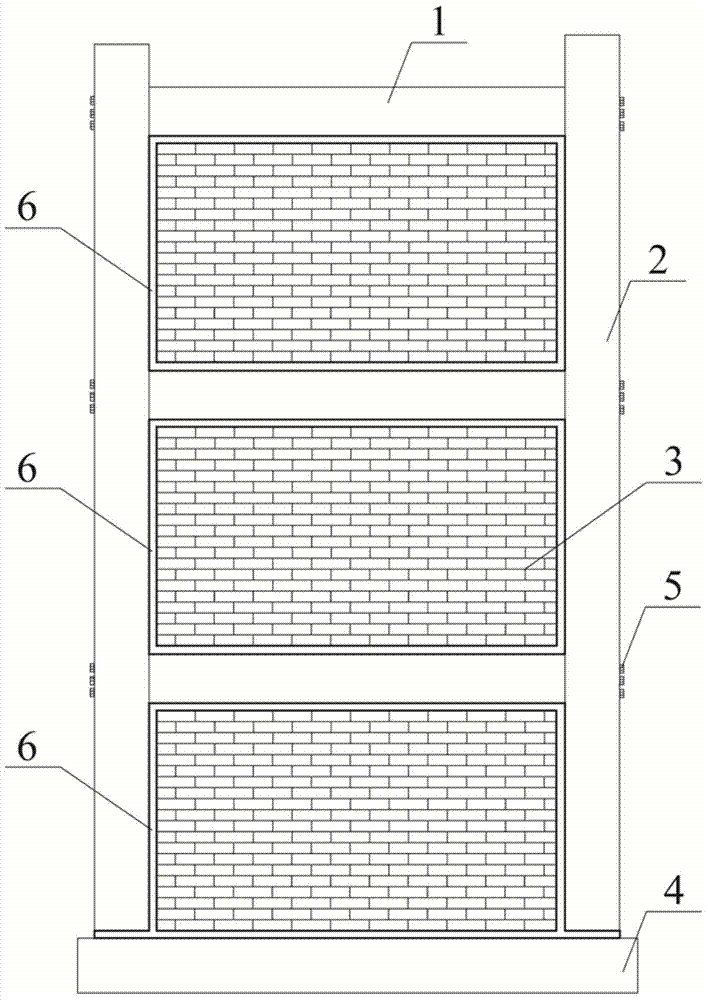

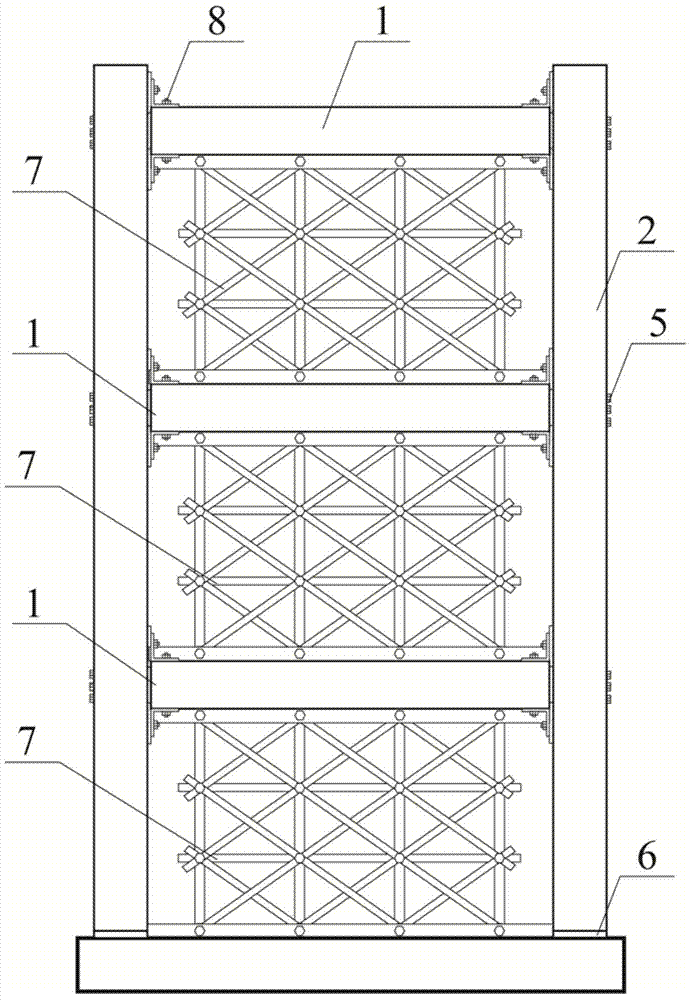

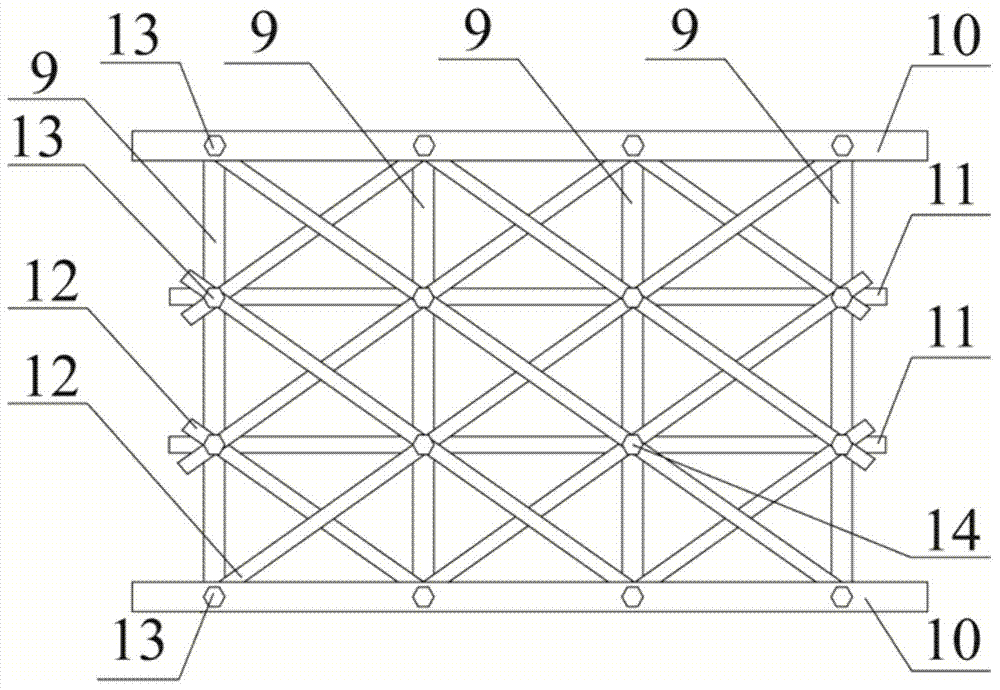

[0020] The self-resetting beam-grid friction wall structure system is composed of self-resetting beam 1, swing column 2 and grid friction wall; multiple self-reset beams 1 are fixed on the swing columns 2 on both sides from bottom to top , use rubber plate 6 to separate the two swing columns 2 from the bottom surface of the foundation 4, so that they can sway under the action of horizontal force; the self-resetting beam 1 and the swing column 2 are fixedly connected with angle steel 16 and bolt 8; prestressed The steel bar 17 is buried in the self-resetting beam 1 by post-tensioning method, and its two ends pass through the reserved holes of the swing column 2, and are anchored on the outside of the swing column 2 through the anchor 5; the grid friction wall is the self-resetting beam 1 and The three-layer wall in the frame unit composed of swing columns 2 has a grid metal structure 7 in the middle and two masonry walls 3 on the outside; the length of the outer horizontal rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com