Stepped composite material wind power anti-seismic tower barrel

A technology of composite materials and anti-seismic towers, applied in wind power generation, installation/supporting configuration of wind turbines, climate sustainability, etc., can solve problems such as disconnection or cracking of towers, high consumption of steel plates, limited bearing pressure, etc. Achieve the effects of improving production and installation efficiency, convenient maintenance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

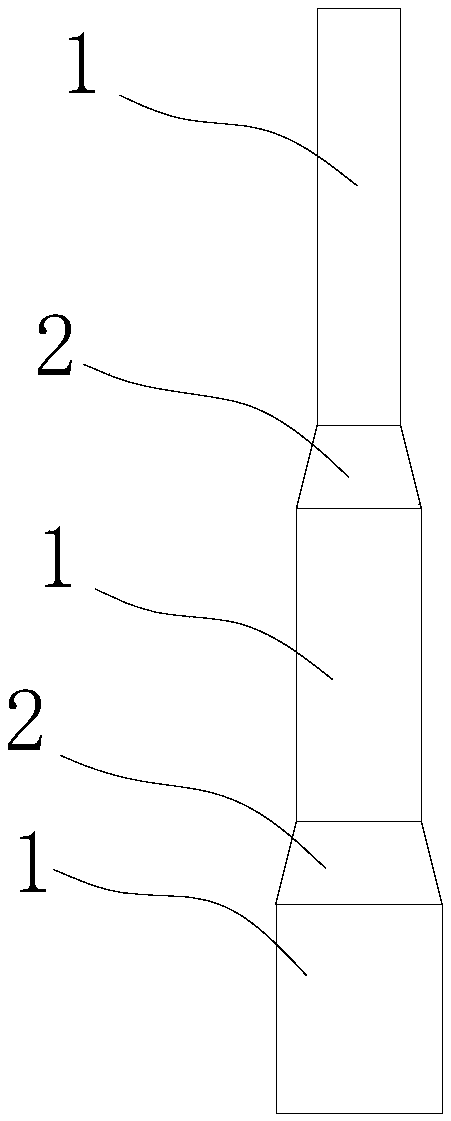

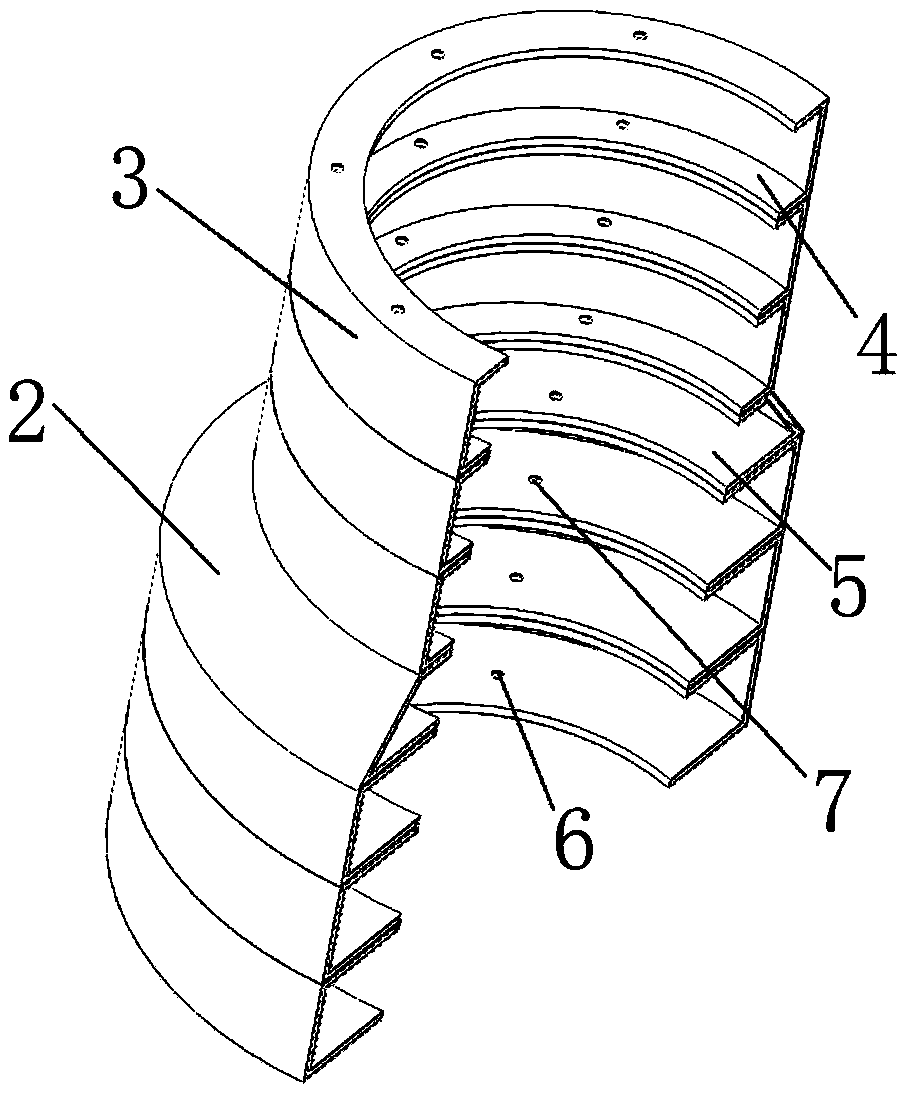

[0031] The gradient composite material wind power anti-seismic tower of this embodiment, such as Figure 1-3 As shown, it is composed of at least two tower sections 1 arranged vertically from bottom to top and a connecting unit 2 connecting adjacent tower sections 1, figure 1 A total of three tower sections 1 and two connection units 2 are shown in . Both the tower section 1 and the connection unit 2 are hollow structures, wherein the outer diameter of the upper tower section 1 is smaller than the outer diameter of the lower tower section 1 .

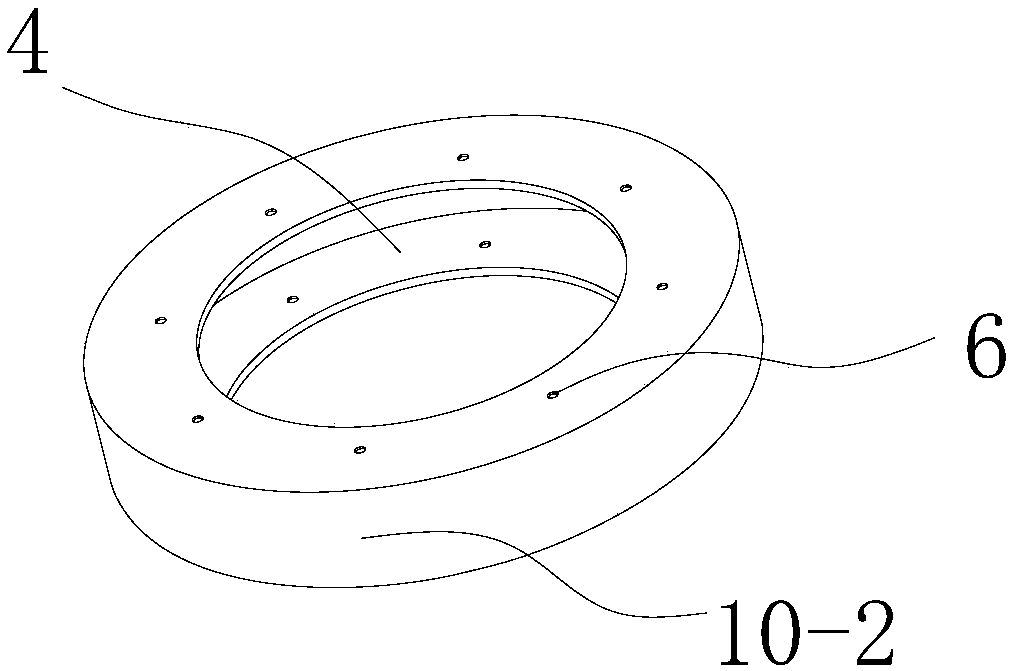

[0032] The tower section 1 is formed by stacking several cylindrical tower units 3, the tower unit 3 includes inner and outer two-layer steel plates, and UHPC layer is filled between the inner and outer two-layer steel plates; as image 3 and Figure 4 As shown, the top and the bottom of the tower unit 3 are provided with first stiffeners 4 extending to the inside of the tower unit 3 and arranged horizontally, and the first stiffeners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com