Plastic wastes dry type cleaning apparatus

A dry cleaning and plastic cleaning technology, which can be used in plastic recycling, solid waste removal, mixers with rotary stirring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described below with reference to the drawings. However, this is one embodiment of the present invention and is not limited thereto.

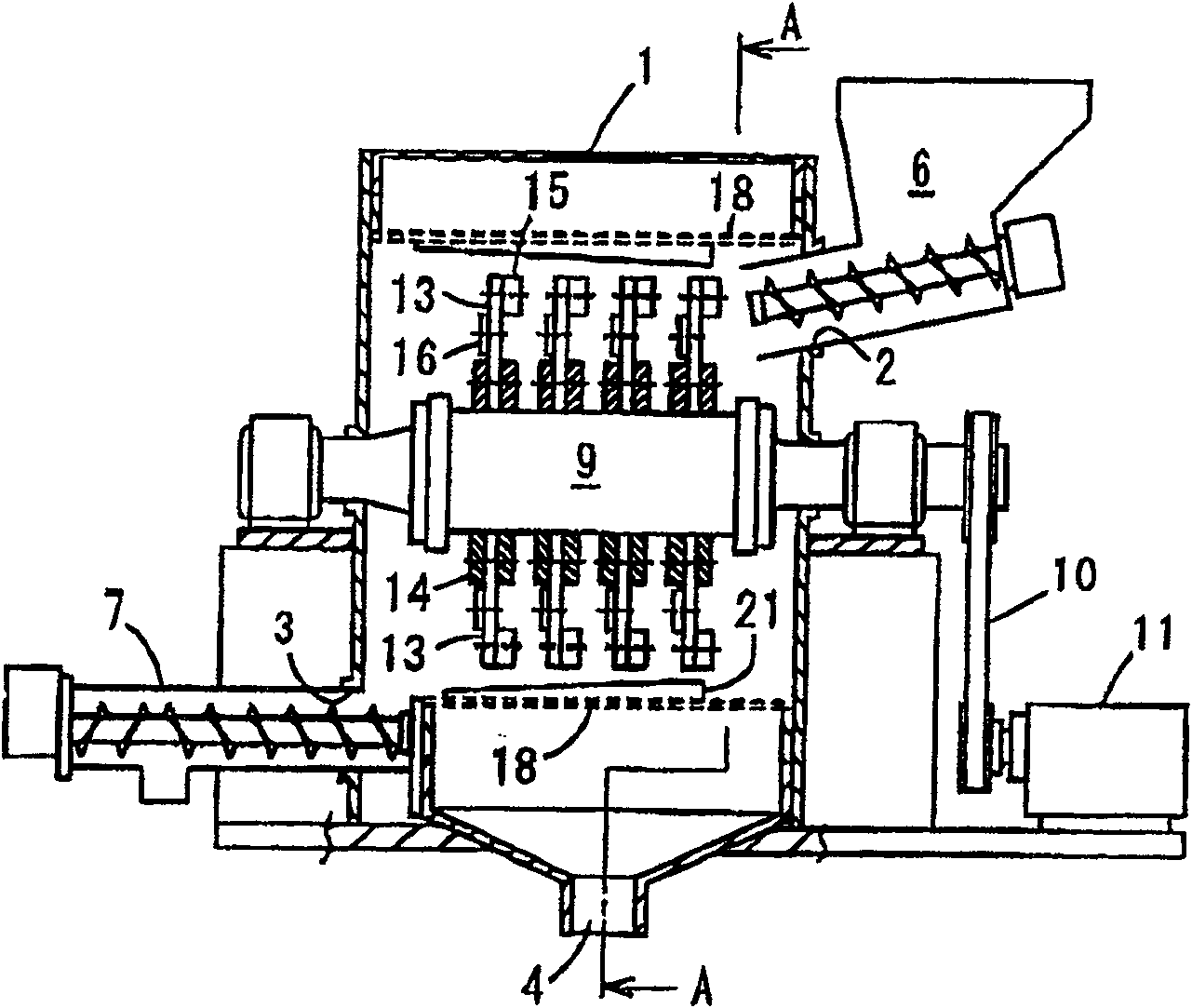

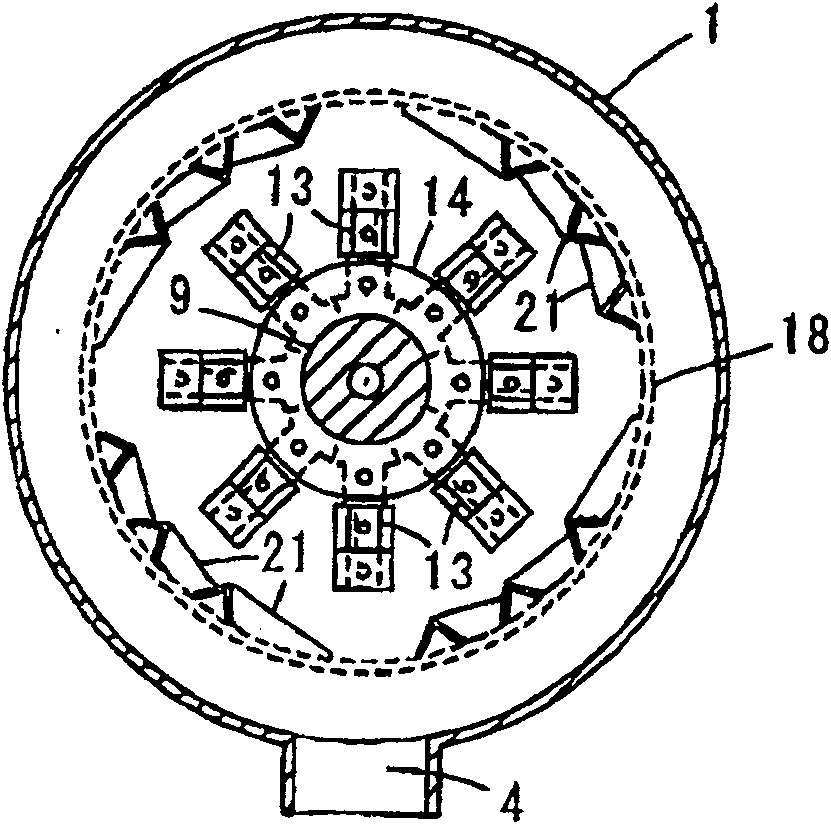

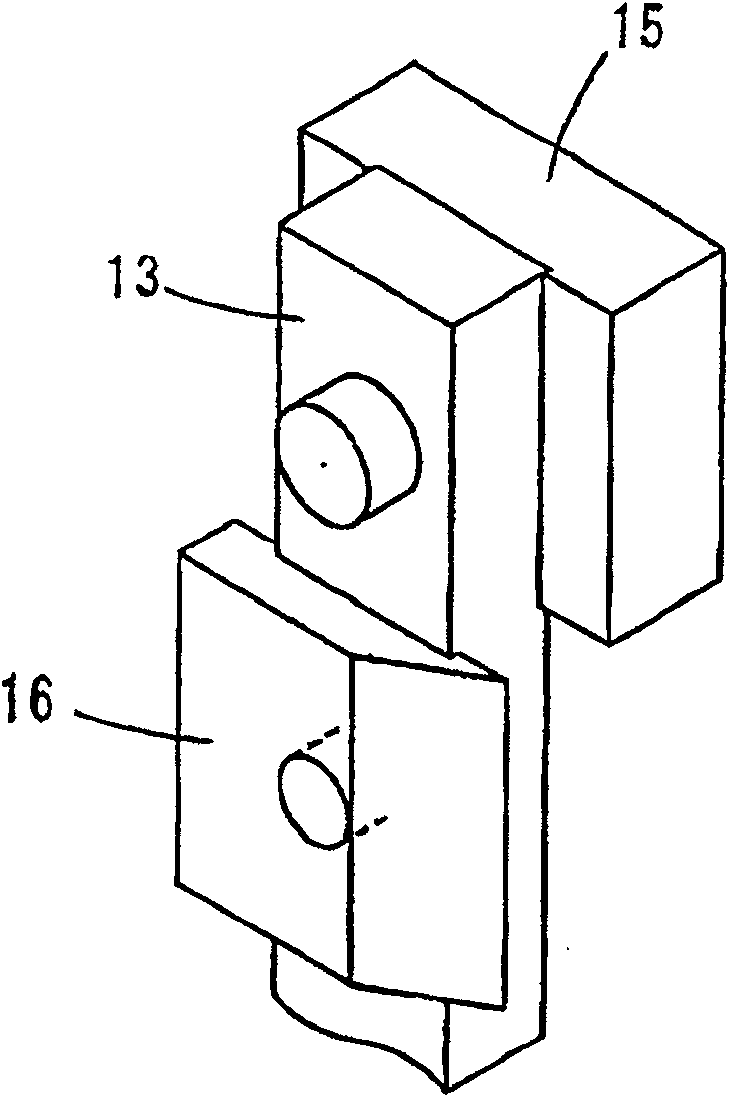

[0048] figure 1 and figure 2 The plastic waste material dry cleaning apparatus concerning 1st Embodiment is shown. This cleaning device is provided with a cylindrical stirring case 1 which is closed at both ends and installed so that the center line is horizontal. A waste material inlet 2 for dropping plastic waste materials is formed on the top of the end plate on the front end side (upstream side) of the stirring housing 1, and a waste material inlet 2 for dropping plastic waste materials is formed on the bottom of the end plate on the rear end side (downstream side). The cleaning material discharge port 3 for discharging the final plastic cleaning material, and further, the attachment discharge port 4 for discharging the attachment matter separated and removed from the plastic waste mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com