LED light source module with heat guiding system and radiation system

A technology of LED light source and heat dissipation system, applied in the field of direct-lit LED backlight modules, can solve the problems of difficult heat dissipation, high temperature of LCD14, affecting the color balance of BLU, etc., and achieve the effect of prolonging the service life and strengthening the heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the structure and effect of the present invention more clearly understood, a preferred embodiment is described below in conjunction with the accompanying drawings as follows:

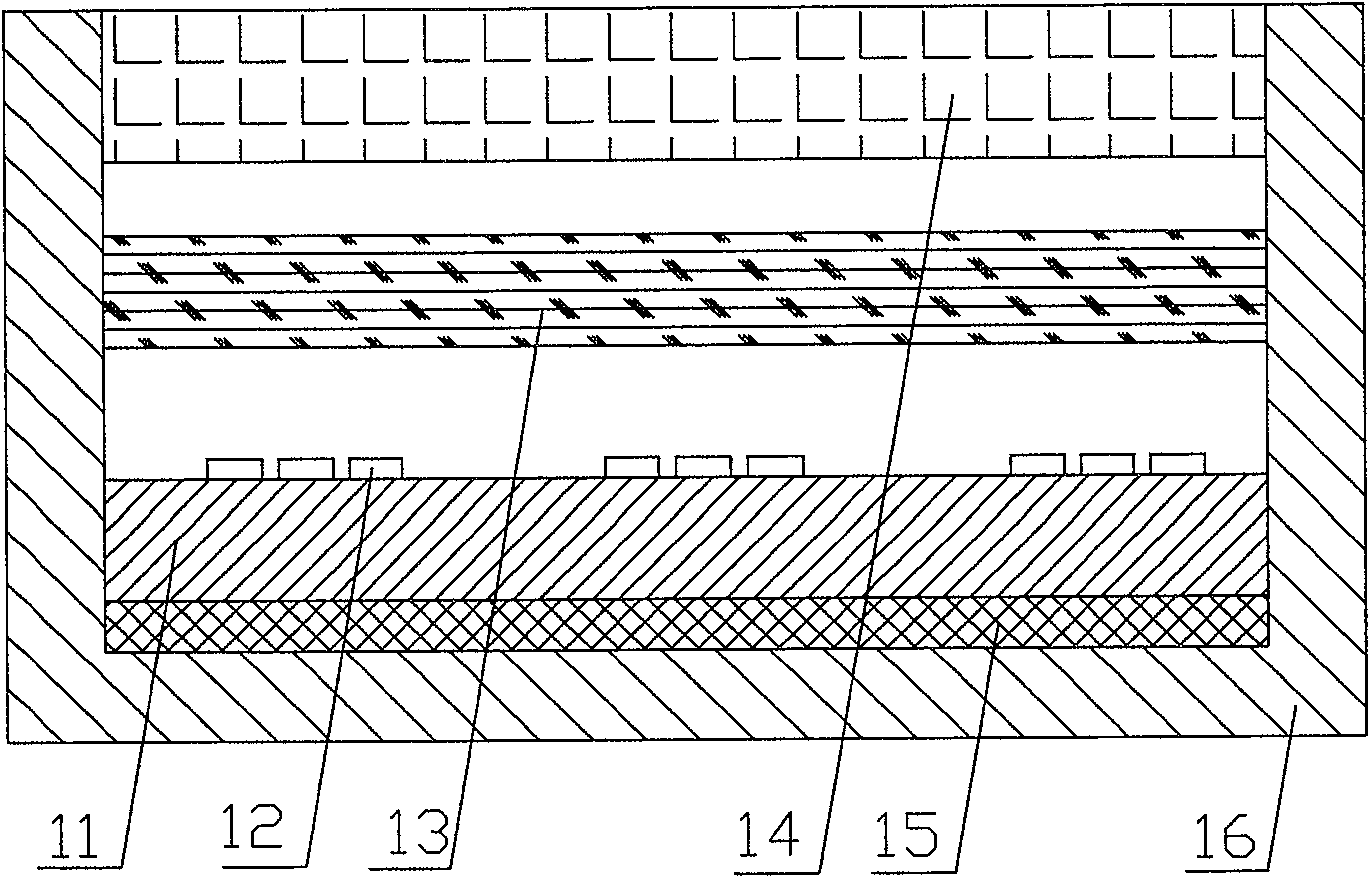

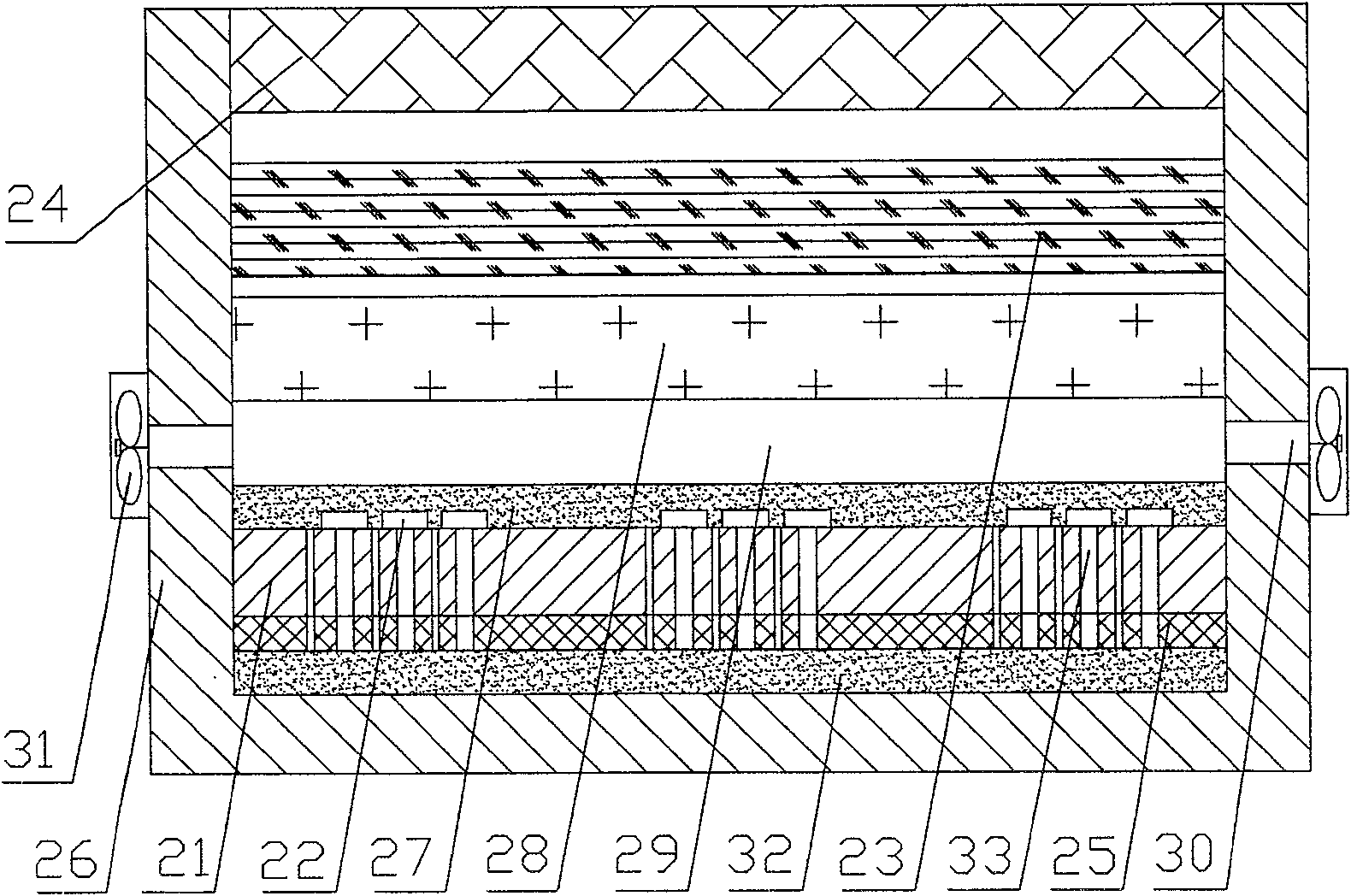

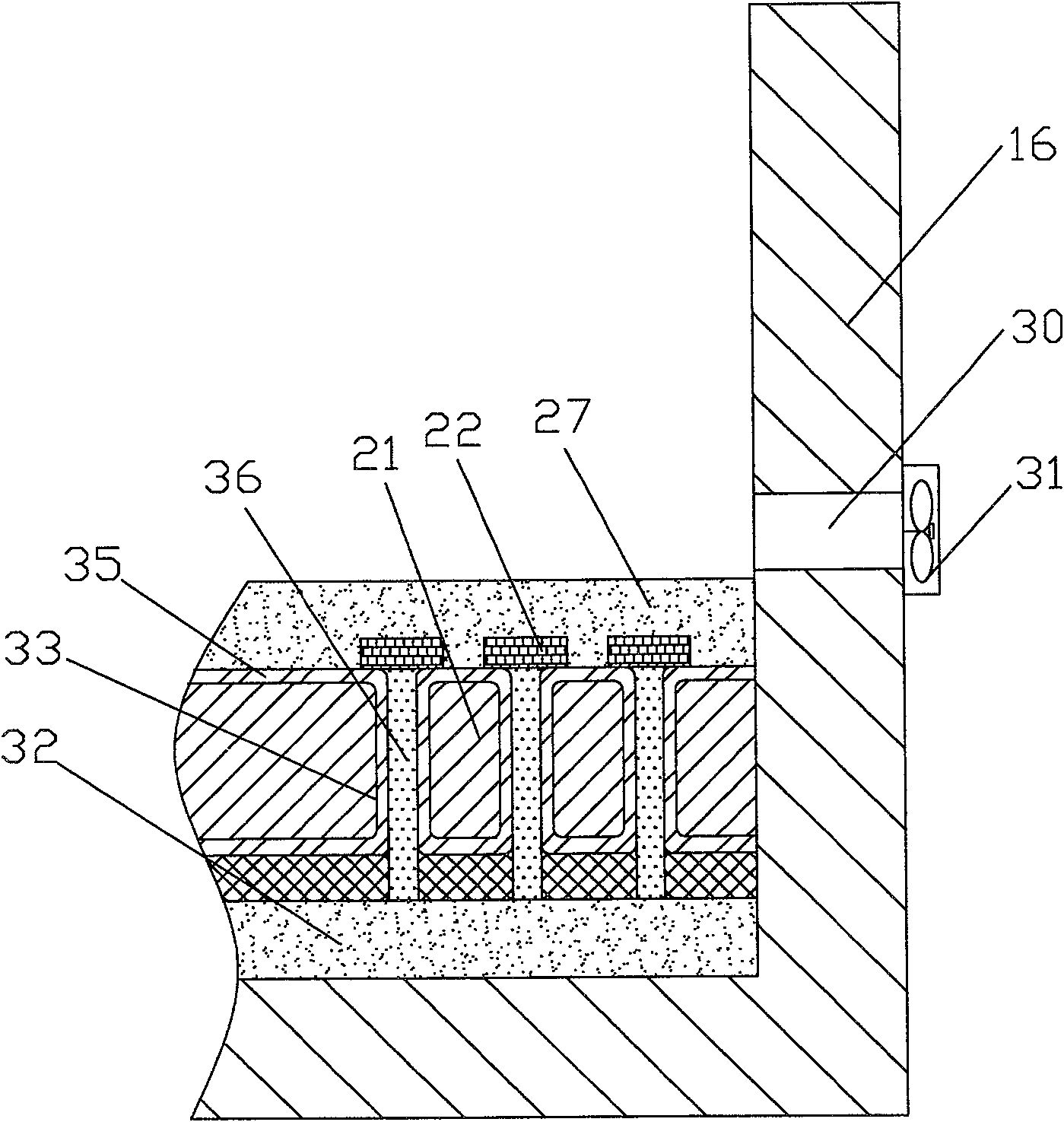

[0024] See figure 2 As shown, it is a preferred embodiment of the present invention, which is a LED light source module with a heat conduction system and a heat dissipation system, which is used in a direct-type BLU, and includes a circuit board 21, and one side of the circuit board 21 is provided with A plurality of LED22, and described LED22 is electrically connected through described circuit board 21; rear output; the other side of the circuit board 21 is provided with a light reflection element 25, and the light reflection element 25 reflects the leaked light of the LED22 upwards, so that the light energy can be fully utilized, and the circuit board 21, light A casing 26 is provided outside the reflection element 25 , the light diffusion element 23 and the light enhancement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com