Photocatalysis aeration filter pool for water treatment

An aeration filter and photocatalysis technology, applied in the field of water treatment, can solve the problems of low treatment efficiency and film shedding, and achieve the effects of high light energy utilization rate, avoidance of shedding, and high mass transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

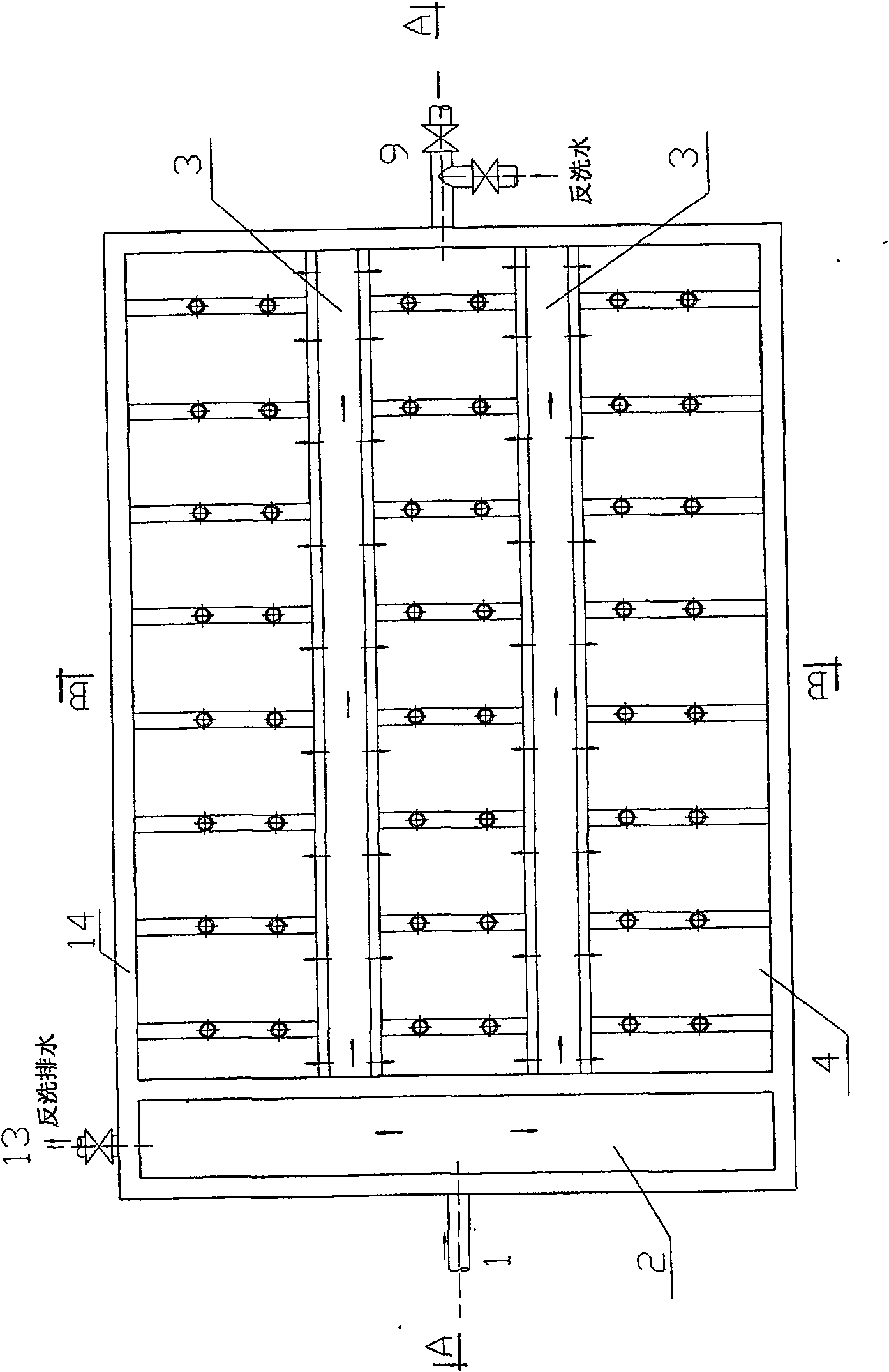

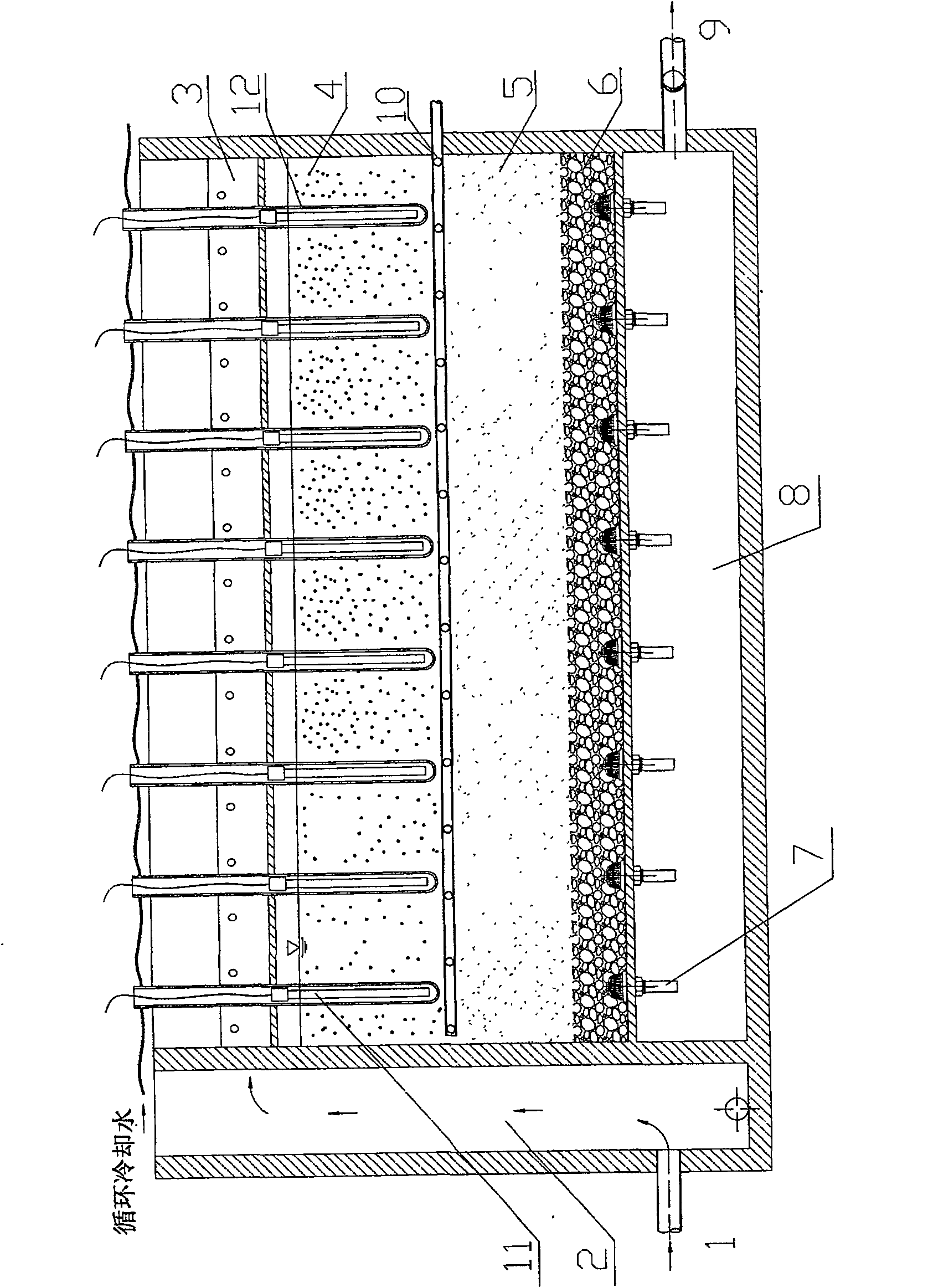

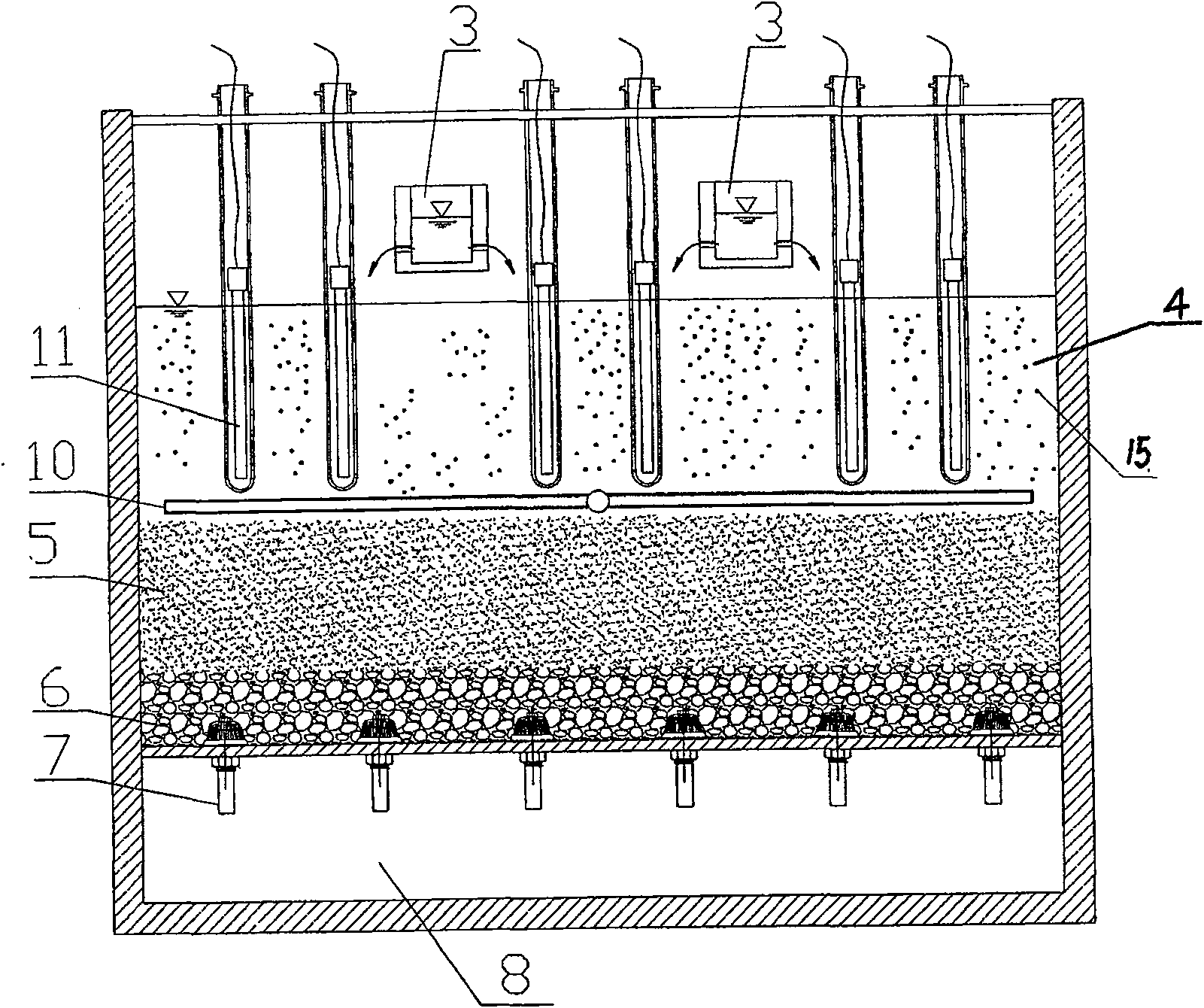

[0030] Embodiment 1: as Figure 1-Figure 4 As shown, the device is a rectangular filter tank surrounded by reaction tank walls 14. The upper part of the aeration filter tank is a water distribution tank 3, the middle is a photocatalytic reaction zone 4, and the lower part is a filter zone; There are circular water distribution holes to ensure that the water is evenly distributed to the photocatalytic reaction zone 4; there is a floating photocatalyst in the photocatalytic reaction zone 4, which is made of hollow glass beads with a diameter of 100-200 μm 15 loaded with nano-titanium dioxide In the photocatalytic reaction zone 4, the ultraviolet lamp tube 11 of the ultraviolet lamp tube overcoat 12 made of quartz glass is vertically arranged to provide a light source for photocatalysis; the bottom of the photocatalytic reaction zone 4 is equipped with an aeration tube 10 to make the device run At this time, the water and the catalyst in the photocatalytic reaction zone 4 are in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com