Method for controlling bubble through temperature to strip two-dimensional material growing on sapphire substrate

A sapphire substrate and two-dimensional material technology, which is applied in the fields of analyzing materials, chemical instruments and methods, and material analysis using wave/particle radiation, can solve the uncertainty of high-temperature-resistant sapphire substrate process conditions and affect the transfer of finished products. Quality and quality stability, cannot well solve the problems of two-dimensional material transfer on the sapphire substrate, and achieve the effect of easy configuration, good scalability, and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

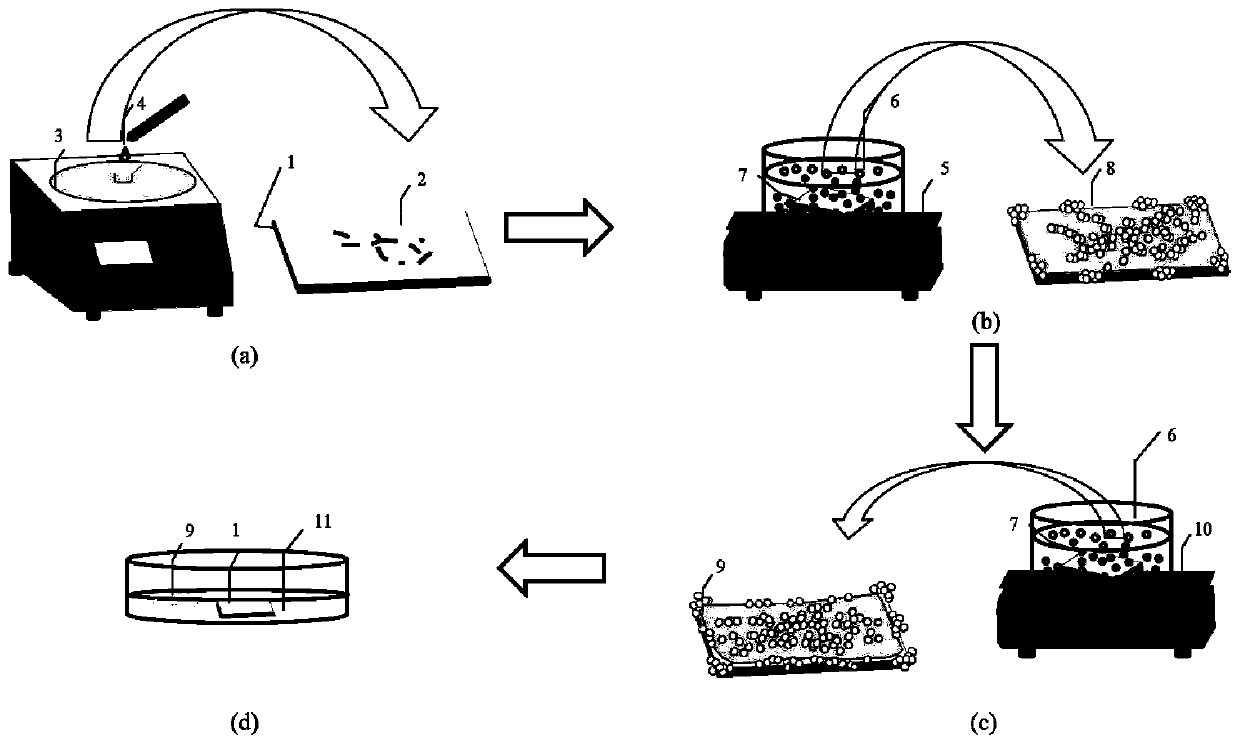

[0022] The two-dimensional material of this embodiment selects tungsten disulfide-molybdenum disulfide heterojunction, see figure 1 The specific preparation process is as follows:

[0023] Step 1: Take a sample of a two-dimensional material grown by vapor deposition on a sapphire substrate, such as figure 1 As shown in (a), set the rotation speed of the homogenizer 3, the forward rotation is 600 rpm, the time is 10 seconds; the backward rotation is 1200 rpm, the time is 60 seconds, and the sapphire substrate 1 is fixed on the homogenization machine by air pressure adsorption 3 on. Use the glue head dropper to take an appropriate amount of PMMA glue drop on the sample surface, cover two-thirds of the sample surface area, start the homogenizer 3, and form a PMMA film 4 with uniform thickness on the surface of the two-dimensional material growth area 2 to obtain a sapphire substrate -Two-dimensional material-PMMA film 7;

[0024] Step 2: Adjust the first heating stage 5 to 150°C, tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com