Centralized processing technique for slop oil and acidic oil and processing system thereof

A centralized treatment and dirty oil technology, applied in the direction of neutralization of water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficult separation of oil, water and impurities without overcoming, Achieve the effects of low cost, simple process, and easy precipitation and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

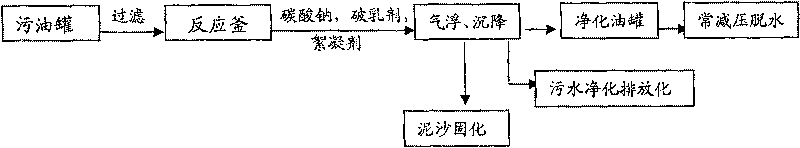

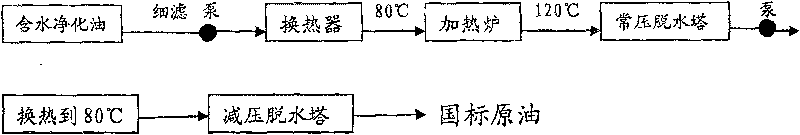

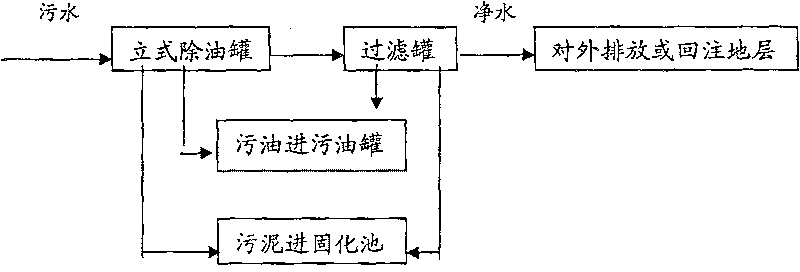

[0059] According to the analysis of X-ray diffractometer, in the dirty oil and sour oil of Jidong Oilfield, the content of large particle impurities accounts for about 1%-2%, the content of fine sediment and other impurities accounts for about 15%-20%, and the content of water The content accounts for about 50%-60%, and the content of pure oil accounts for about 20-30%. After the "blue filter" initially filters out the larger sediment impurities in the dirty oil. The dirty oil that has been filtered out of large particles of impurities is pumped into the reaction kettle to decompose the sediment and oil and water. Inject compressed air from the coil with a pore diameter of 80 μm at the bottom of the reactor to generate fine bubbles with a diameter of about 80 μm for stirring, add 10% sodium carbonate solution to the dirty oil to stabilize the pH value of the dirty oil at 7.2, and then Add PR-02 type demulsifier with 0.6% volume of dirty oil in the kettle, then add flocculant ...

Embodiment 2

[0061] Dirty oil and sour oil are filtered through the "blue filter", and the filtered dirty oil is pumped into the reaction kettle through the "HF-B01-LCR Roots Oil Pump". When the dirty oil in the reaction kettle is heated to 60°C, Compressed air is injected into the coil with a pore diameter of 90 μm at the bottom of the kettle to generate fine bubbles with a diameter of about 90 μm for stirring, and 15% sodium carbonate solution is added to the dirty oil to stabilize the pH value of the dirty oil at 7.5, and then the kettle When the temperature of the dirty oil in the tank is increased to 80°C, add HF-01B type demulsifier with 0.7% volume of dirty oil in the tank, then add HF-02 flocculant with 0.4% volume of dirty oil in the tank to continue the reaction, and inject compressed air The duration of the process is 3.5 hours; stop injecting compressed air, and let it settle for 6 hours; input the purified oil in the upper layer of the reactor into the purified oil tank, the se...

Embodiment 3

[0067] The dirty oil is filtered through the "blue filter", and the filtered dirty oil is pumped into the reactor through the "HF-B01-LCR Roots Oil Pump". When the dirty oil in the reactor is heated to 50°C, The coil with a diameter of 60 μm is injected with compressed air to generate fine bubbles with a diameter of about 60 μm for stirring, and the HF-B02-IMC stainless steel magnetic drive pump is used to add 7% sodium carbonate solution to the dirty oil to make the pH of the dirty oil The value is stable at 6.0, and then when the temperature of the dirty oil in the kettle is increased to 70°C, then add HF-01B type demulsifier with 0.8% volume of dirty oil in the kettle, and then add HF-02 type with 0.2% volume of dirty oil in the kettle The flocculant continues to react, and the duration of injecting compressed air is 2.5 hours; stop injecting compressed air, and let it settle for 6 hours; input the purified oil in the upper layer of the reaction kettle into the purified oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com