Dyeing machine capable of improving bath liquid distribution status and circulation

A dyeing machine and state-of-the-art technology, applied in the field of dyeing machines, can solve problems such as unevenness, light coloring of fibers, failure to meet dyeing requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

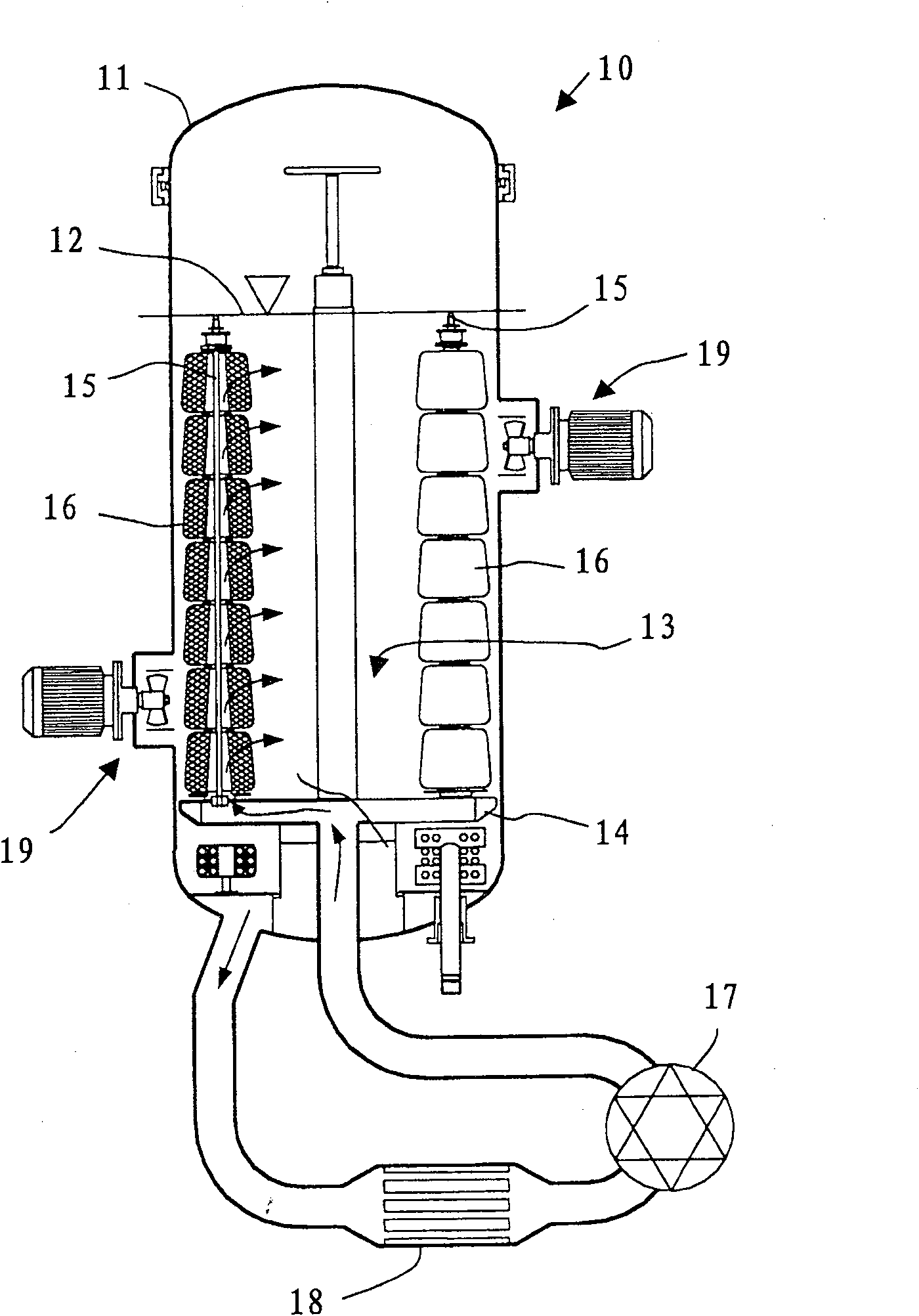

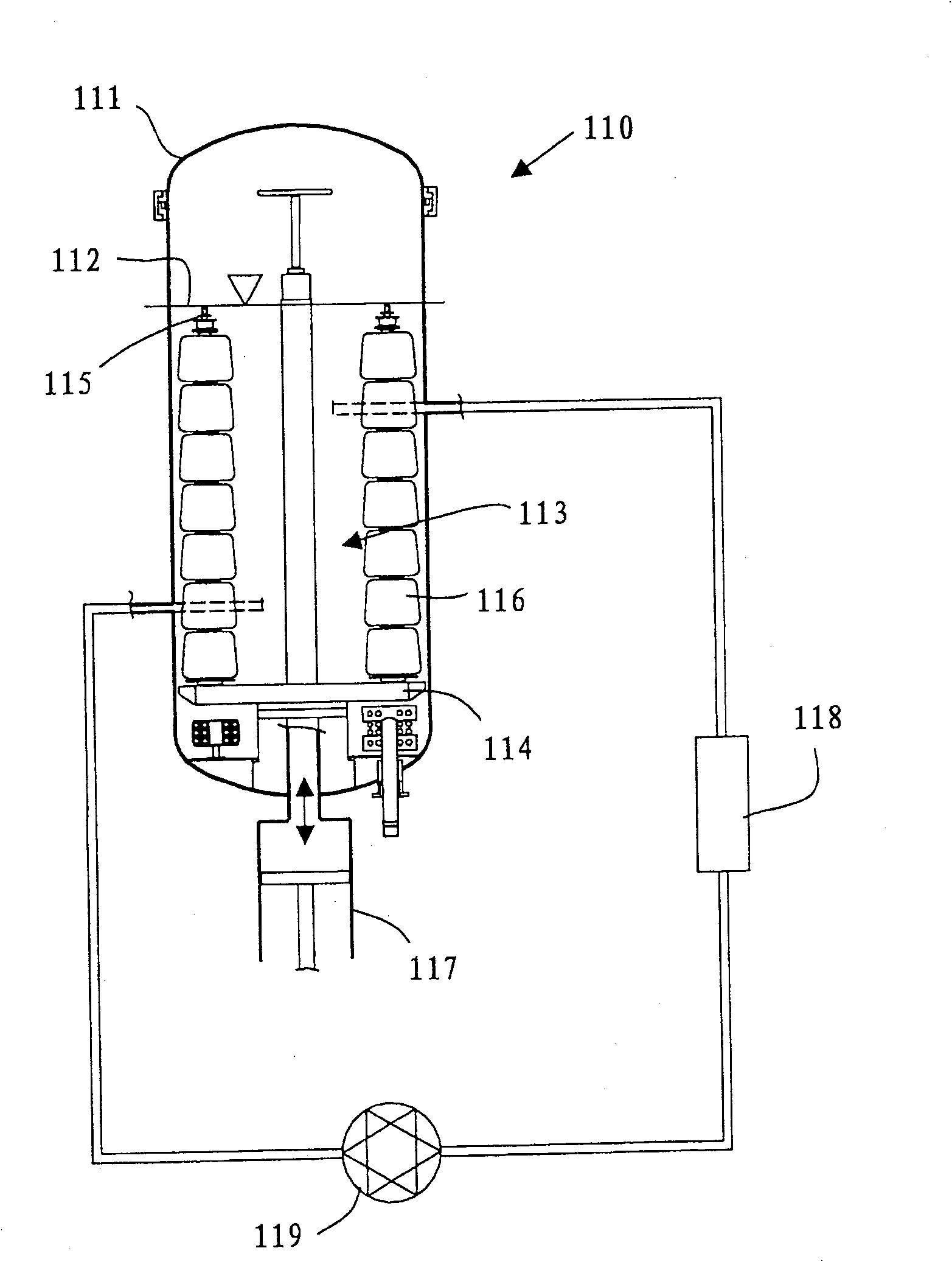

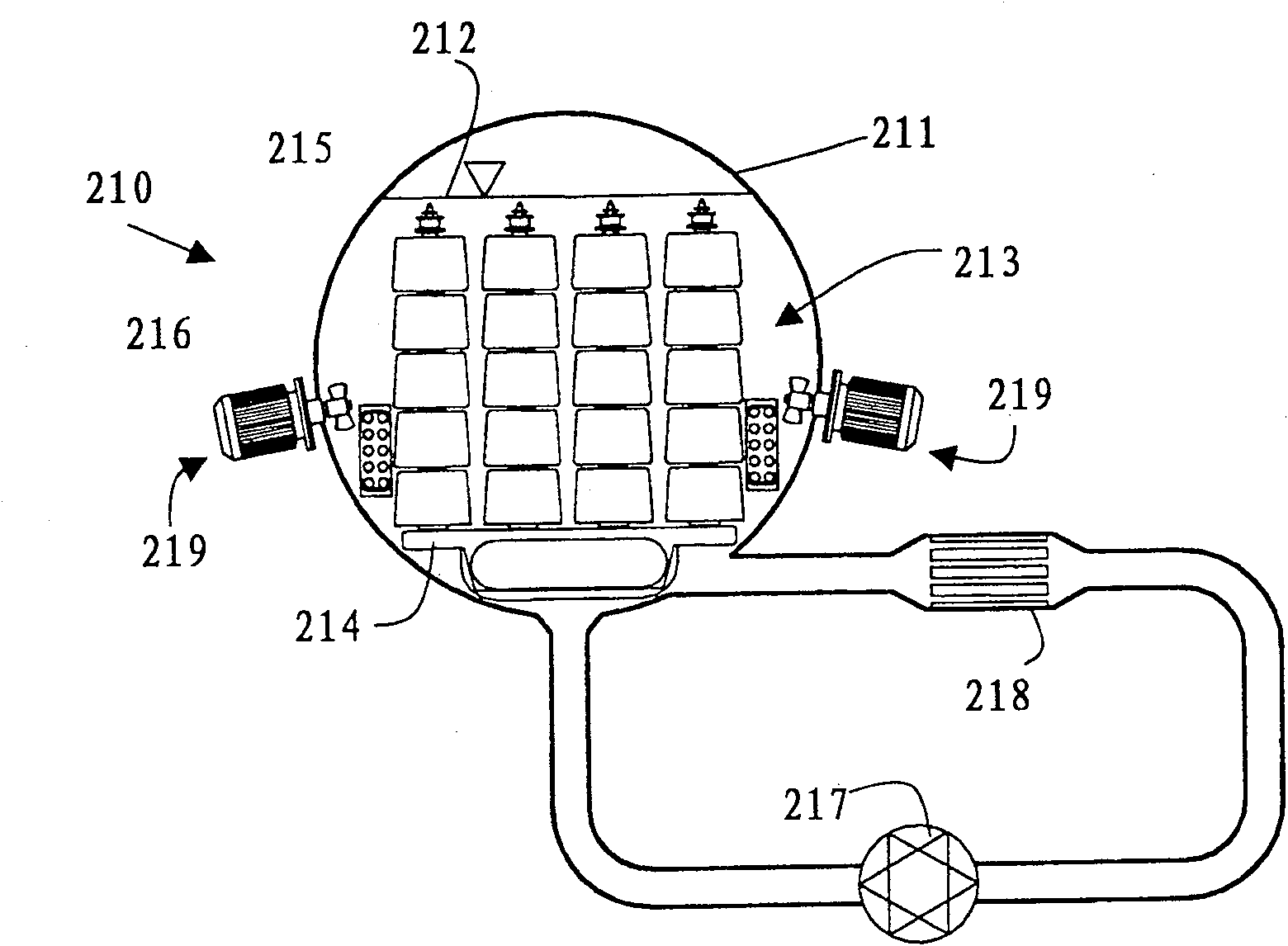

[0020] With reference to the accompanying drawings, figure 1 The textile material dyeing machine of embodiment 1 is shown, and its whole is designated by numeral 10 . In particular, the type of dyeing machine known as "vertical" (generally extending vertically and with doors closing above) is designed to dye such materials wound on bobbins or cones. The materials may be, for example, yarns, pre-yarn ribbons, filler threads, and the like. Conical bobbins can be rigid or compressive.

[0021] The dyeing machine comprises a pressurized container 11 intended to be filled to level 12 with a specific liquid constituting the dyeing liquor. In the container there is a material holder or bracket 13 (liftable and removable) for supporting the textile material immersed in the dye liquor. In this embodiment, the bracket comprises a base 14 from which vertically protruding rods 15 (for example arranged in a circle) serve to axially support the textile material wound on a bobbin 16 . A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com