Preparation method of light foam concrete and its main machine

A lightweight foam and concrete technology, applied in clay preparation equipment, mixing operation control, chemical instruments and methods, etc., can solve the problems of difficulty in ensuring the quality of lightweight foam concrete, inaccurate measurement of raw materials, and unstable foam quality. Achieve the effects of convenient control and adjustment, convenient up and down transportation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

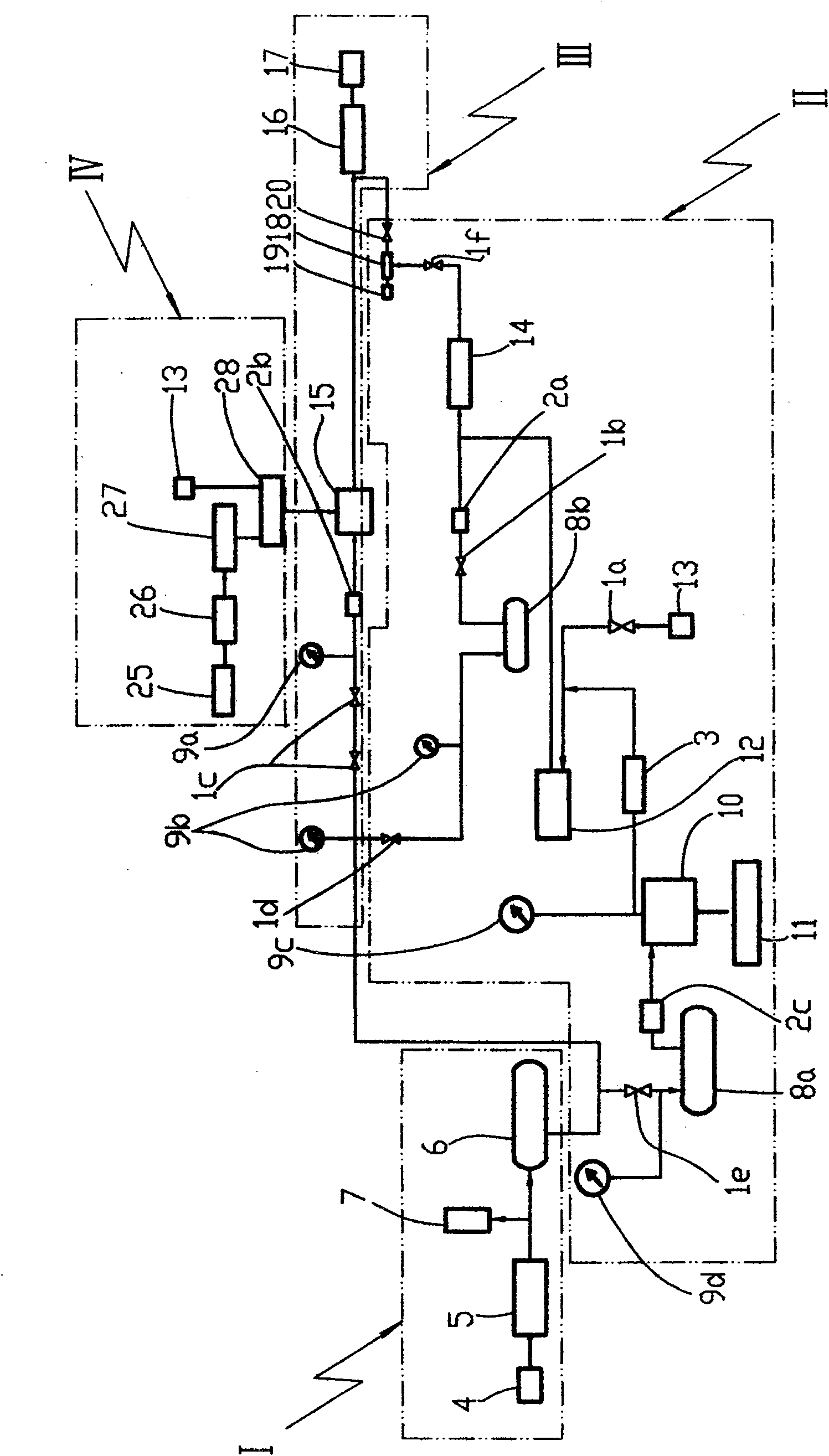

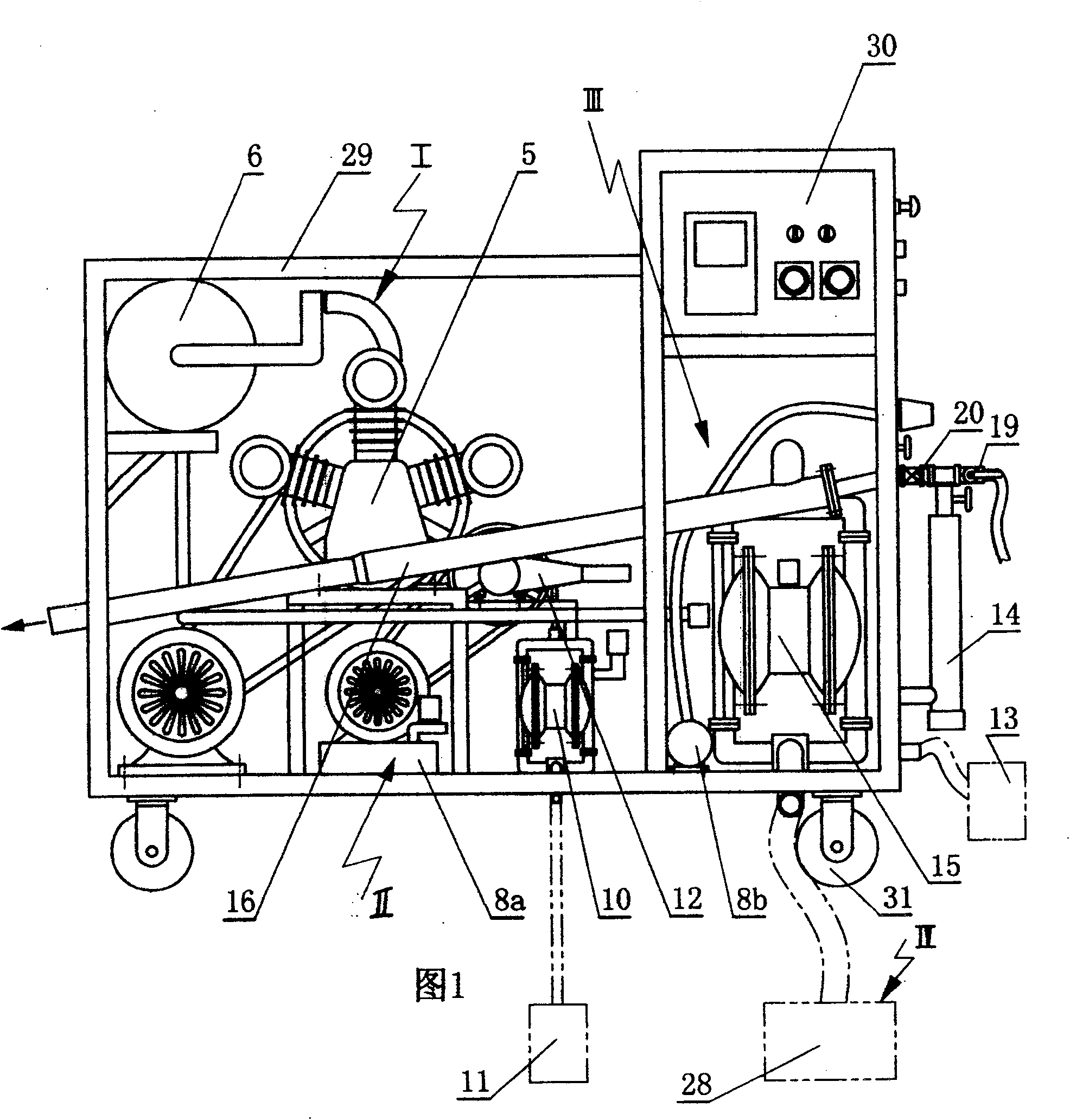

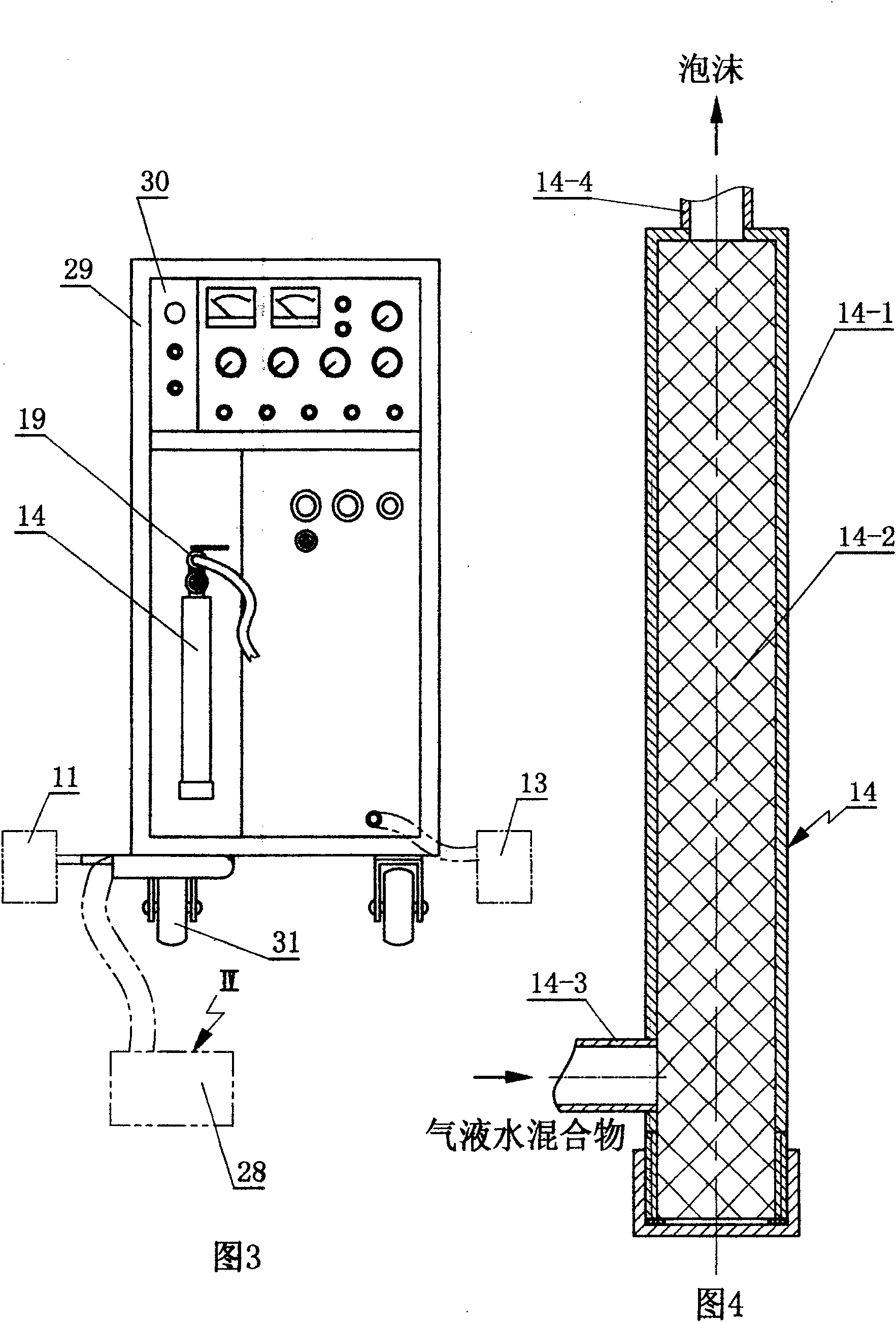

[0041] The present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

[0042] The specific embodiment of the said preparation method of the present invention, as attached figure 1 shown, and please refer to the attached Figure 8 .

[0043] A kind of preparation method of lightweight foamed concrete, comprises adopting to prepare foam by foamer 14 that main frame comprises, adopts the mixer 28 of the usual mud preparation equipment that is matched with main frame to prepare mud, and the mixer 16 that is comprised by main frame The mud and foam are mixed to prepare the finished lightweight foam concrete and output it. In solving the metering and mixing of the foaming agent, water and compressed air for foam preparation, manual adjustment valves 1a, 1b and adjustable electronic valves with adjustable flow are used for 3 phases Combined control technology, and the commonly used foam working pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com