Blocking device of the unwinding of threads from the feeding bobbins of a double-torque twister

A technology for blocking device and yarn, applied in the field of yarn control, can solve the problems of difficult operation process, increased tension of conveyor belt, danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

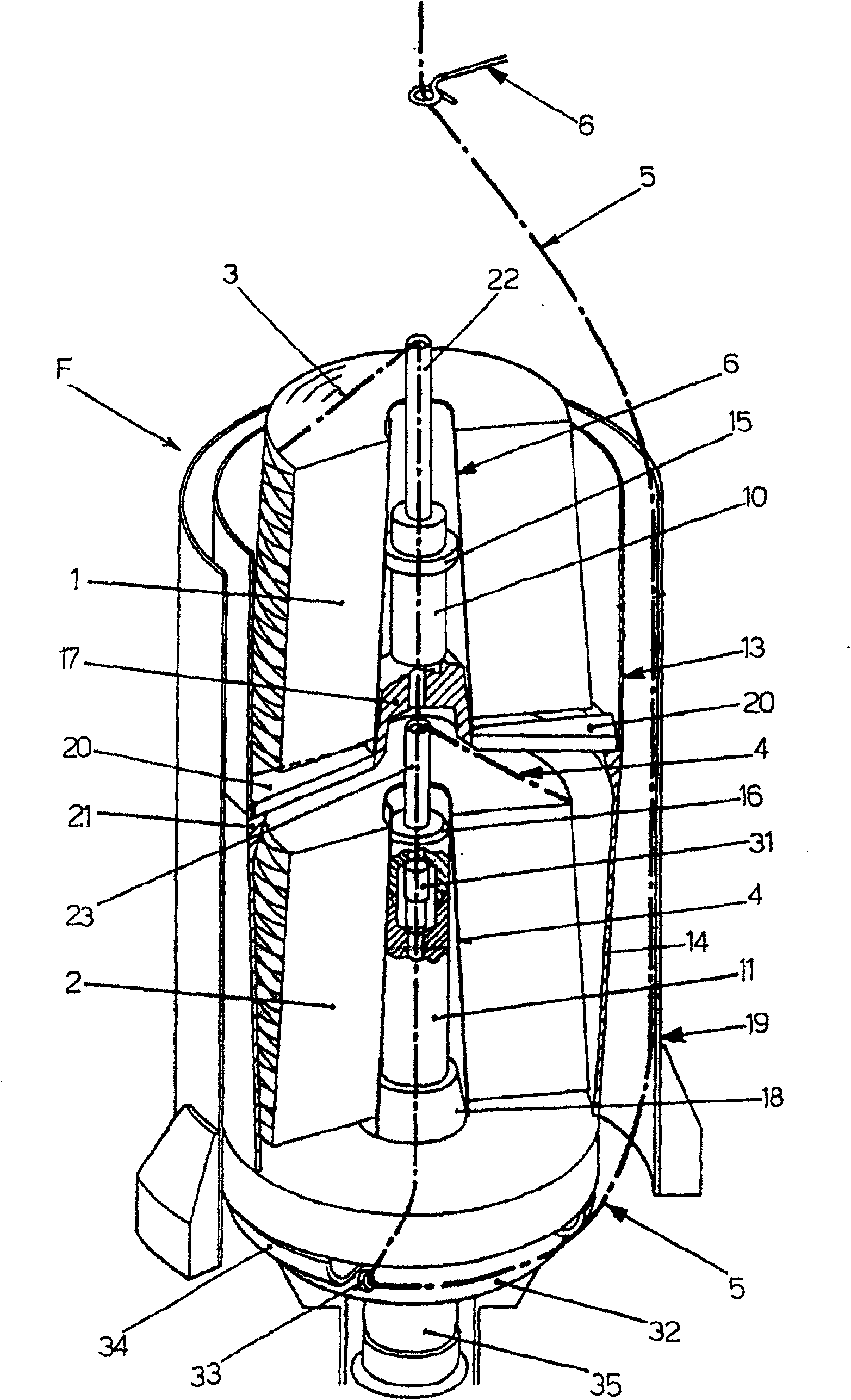

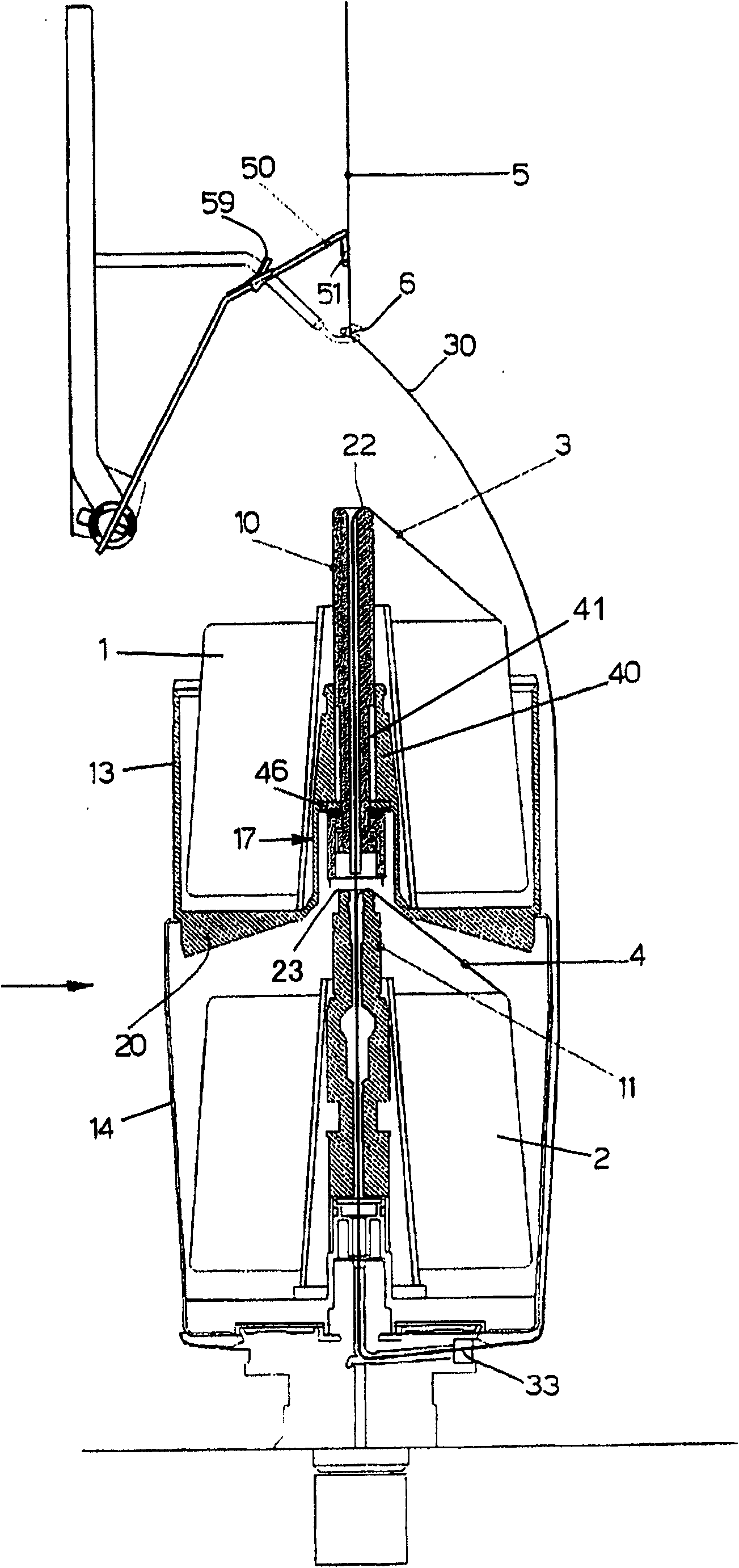

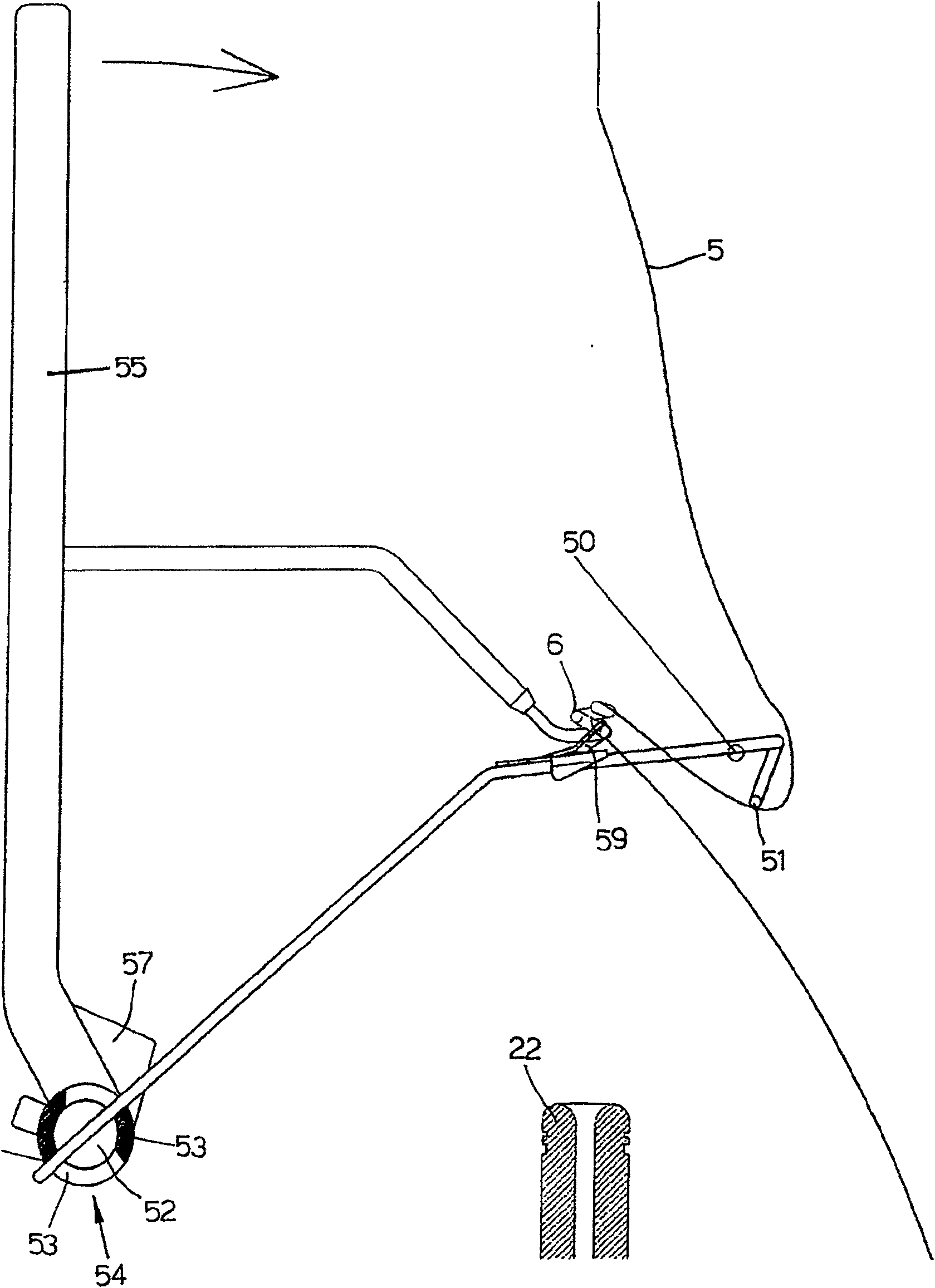

[0033] figure 2 It is a schematic diagram of the twisting station in normal operation. The feed consists of two yarns 3, 4 coming from yarn supply bobbins 1, 2 in cylindrical baskets 13, 14 and inserted into their unwinding heads comprising The upper ends 22, 23 of the hollow pins 10, 11. The yarns 3, 4 pass through the holes of the pins 10, 11 continuously and are twisted at the bottom of the spindle F, and the two-for-one twisted yarn 5 goes upward outwards and is collected at the upper part.

[0034] The two yarns 3, 4 are unwound at the pull rate of the twisted yarns and rotate around their supply bobbins while passing through the tops of the hollow pins 10, 11. To reduce wear on the yarn run, the tops of these hollow pins are protected by smooth circular metal washers.

[0035] The two-for-one twisted yarn 5 leaves the hole 33 on the rotating disk 32 rotating at high speed, and its balloon is first controlled by the inner wall of the cylindrical casing 19, and then by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com