Empty burning controller for boiler

A technology for controllers and stoves, which is applied in the fields of stove flame controllers and stove empty-burning controllers. It can solve the problems of undiscovered solutions, waste of cooking stoves for chefs, etc., and achieve the effects of novel structure, reduced firepower, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

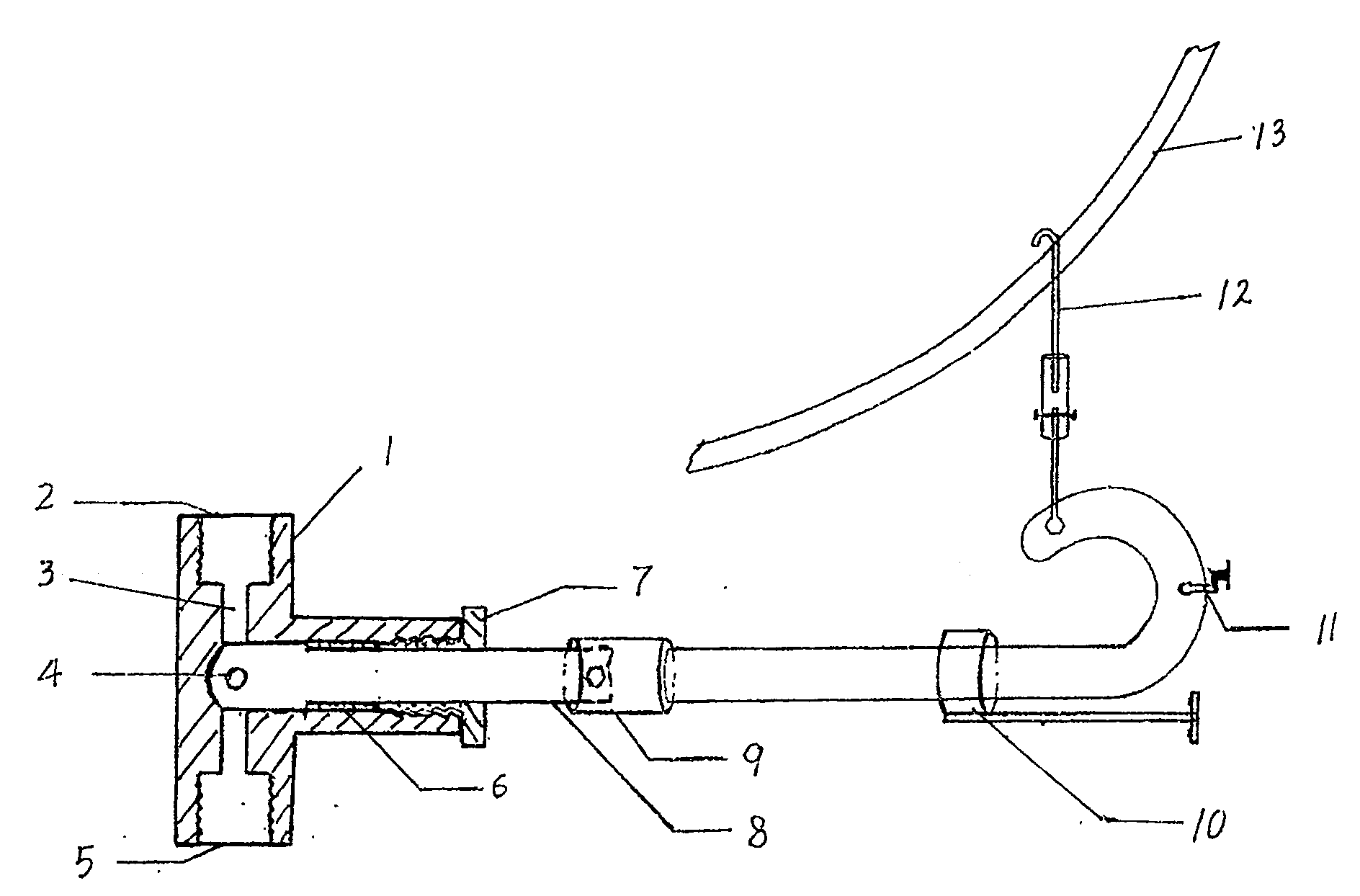

[0014] In the figure, one end of the vertical arm of the sleeve head 1 is provided with an air source inlet 2, and the other end is provided with an air source outlet 5, and an air source channel 3 is provided between the air source inlet 2 and the air source outlet 5, which is located on the shaft 8 The air flow control hole 4 at the end is facing the air source channel 3 . Unscrew the gas valve, the gas enters from the gas source inlet 2, passes through the gas source channel 3 and the gas flow control hole 4, flows out from the gas source outlet 5, and then burns for the stove. When the frying pan is placed on the stove pot ring 13, the pot body contacts the top tie rod 12 and presses it down. Since the lower end of the top tie rod 12 is connected to the hook part of the steering rod 9, the rotation of the steering rod drives the rotation of the shaft rod 8. , so that the air flow control hole 4 on the shaft is facing the air source channel 3, the air flow is normal, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com