Cooling plate

一种冷却板、冷却剂的技术,应用在冷却装置、炉子冷却装置、炉冷等方向,能够解决铜的焊接技术昂贵、高故障风险、费用高等问题,达到提高疲劳寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

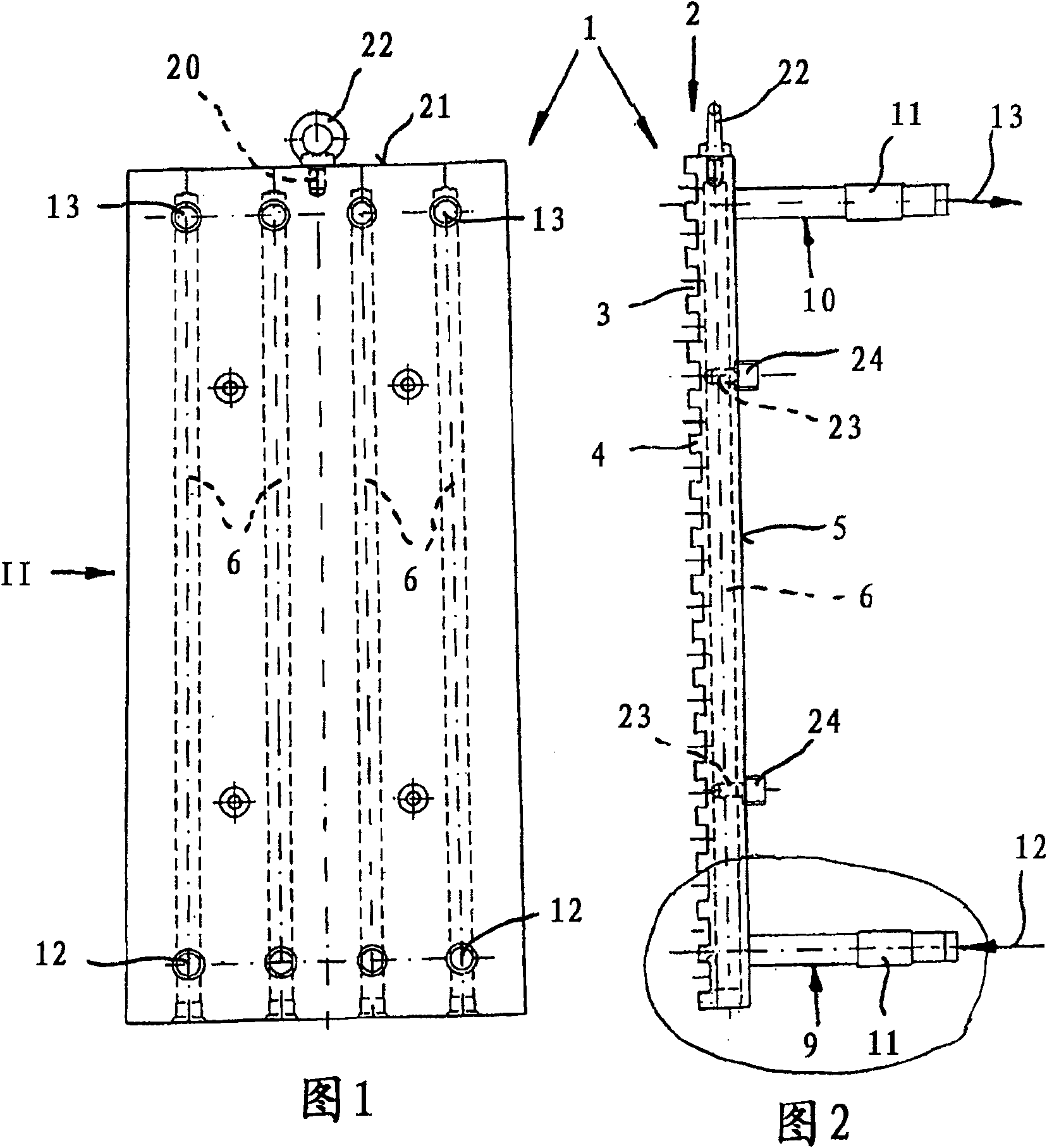

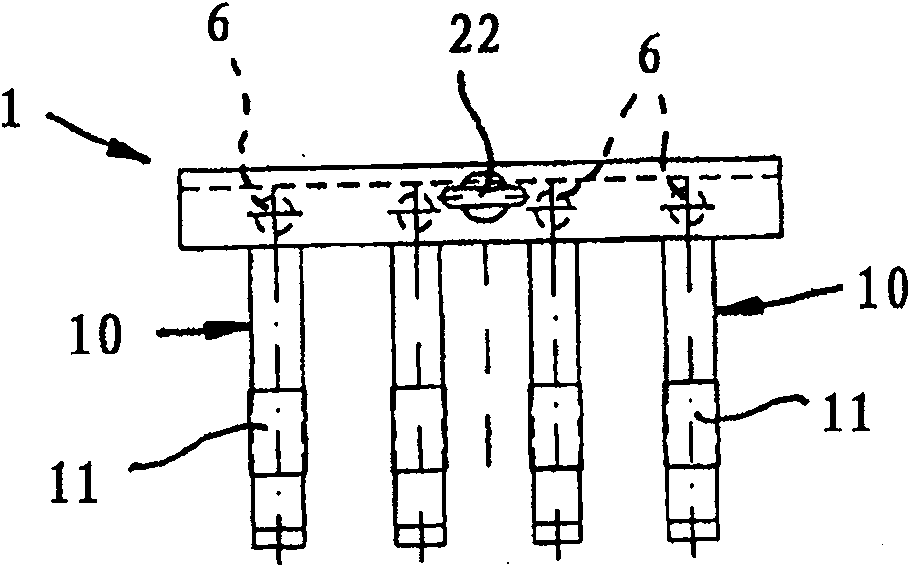

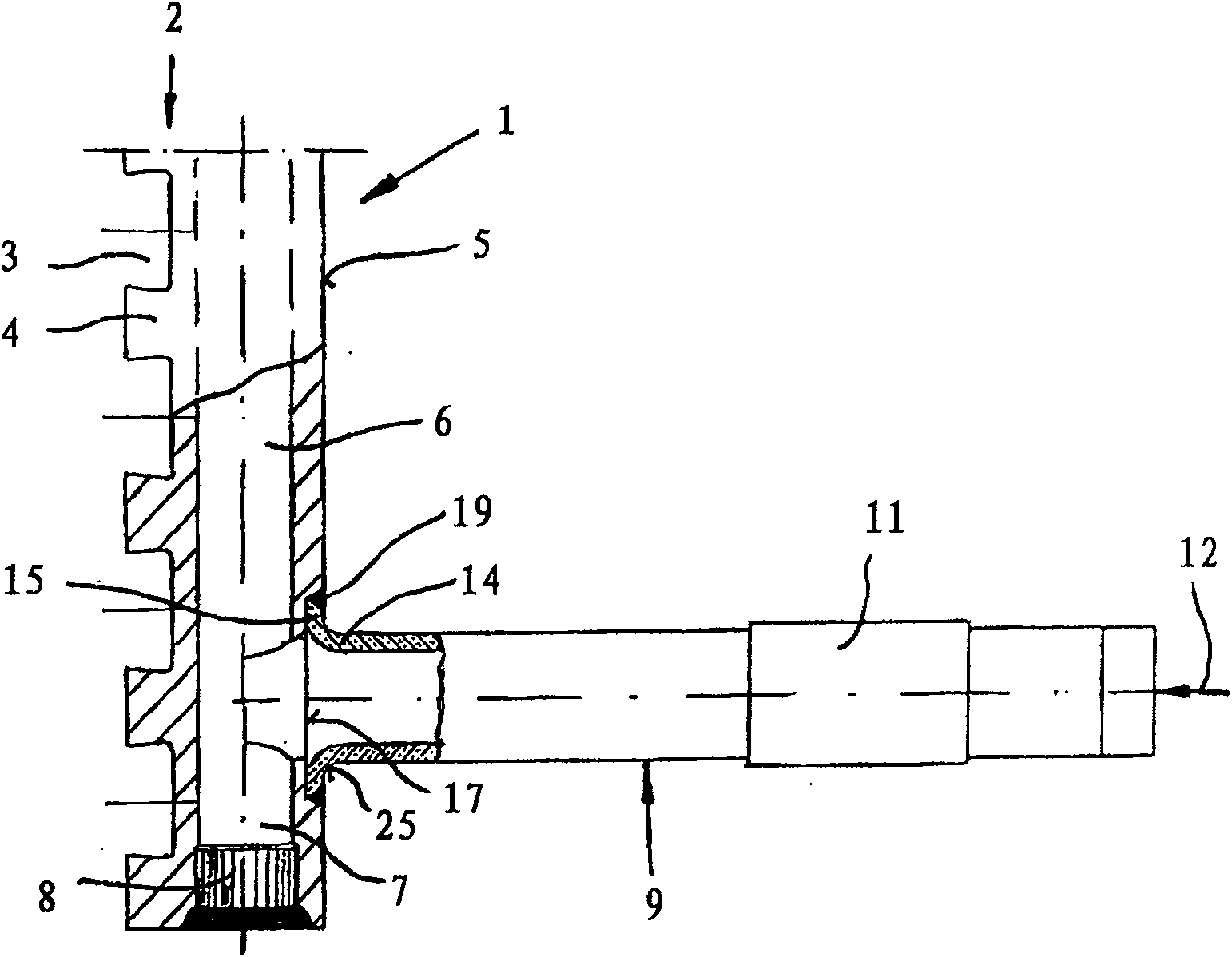

[0026] exist Figures 1 to 5 A cooling plate made of copper or a copper alloy for a well-type furnace is indicated by the numeral 1 in it. The cooling plate 1 alternately has grooves 3 and projections 4 on the hot side 2 of the plate. The cooling plate 1 has a planar design on the plate cold side 5 .

[0027] A plurality of bores 6 forming deep bores for receiving a coolant, such as water in particular, are provided on the cooling plate 1 . The bores 6 designed as blind bores have a plug 8 at the inlet end 7 .

[0028] The bores 6 can be connected individually or also in groups (with a correspondingly reduced diameter) to connecting pipes 9 , 10 . exist Figures 1 to 5 Among them, each hole is connected with a connecting pipe 9, 10, leading to coolant. However, it is also conceivable that the holes 6 of smaller diameter are combined in groups (two to four holes 6) in the region of the connecting pipes 9, 10, and then these holes 6 are connected to the connecting pipes via...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com