Forging forming technology of V-shaped-cavity forged piece

A forging and forging technology, applied in the forging and forming process of V-cavity forgings, can solve the problems of low material utilization, thick heat treatment section, and low mechanical properties, so as to improve mechanical properties, increase production efficiency, and improve metal flow direction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the invention with reference to the drawings in the embodiments of the invention.

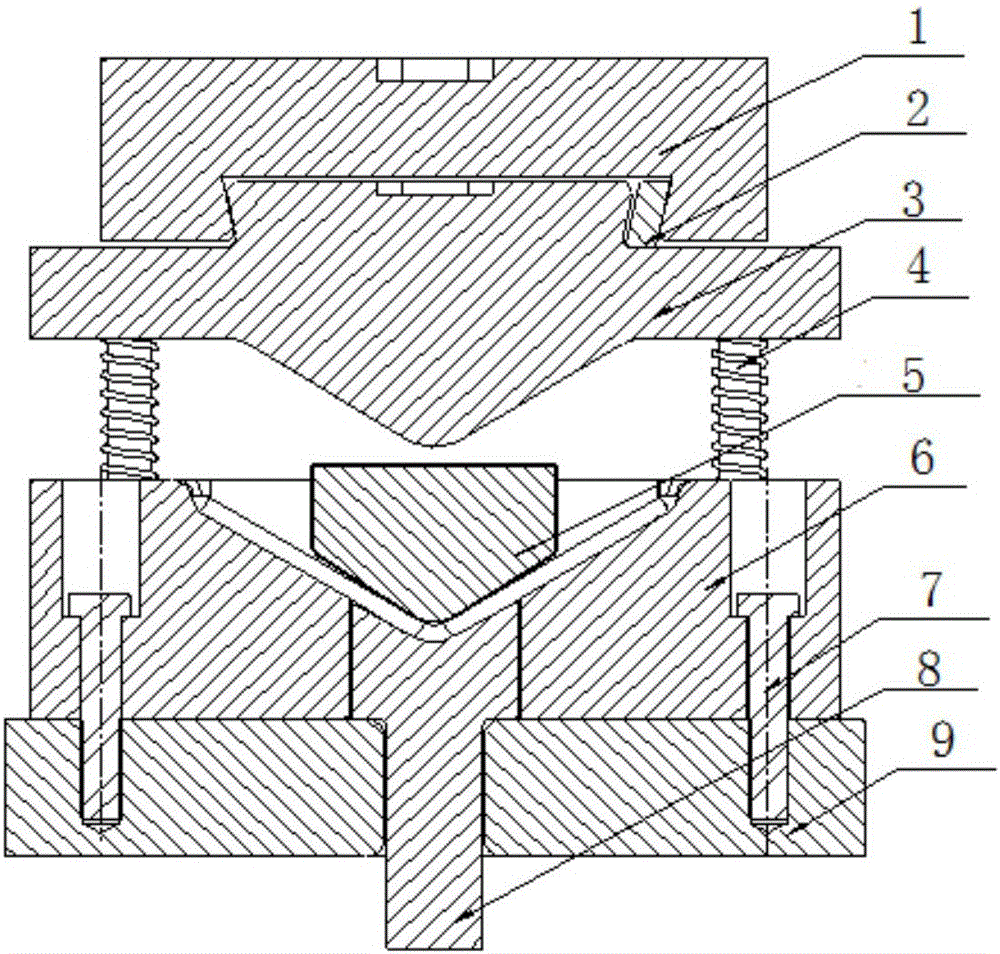

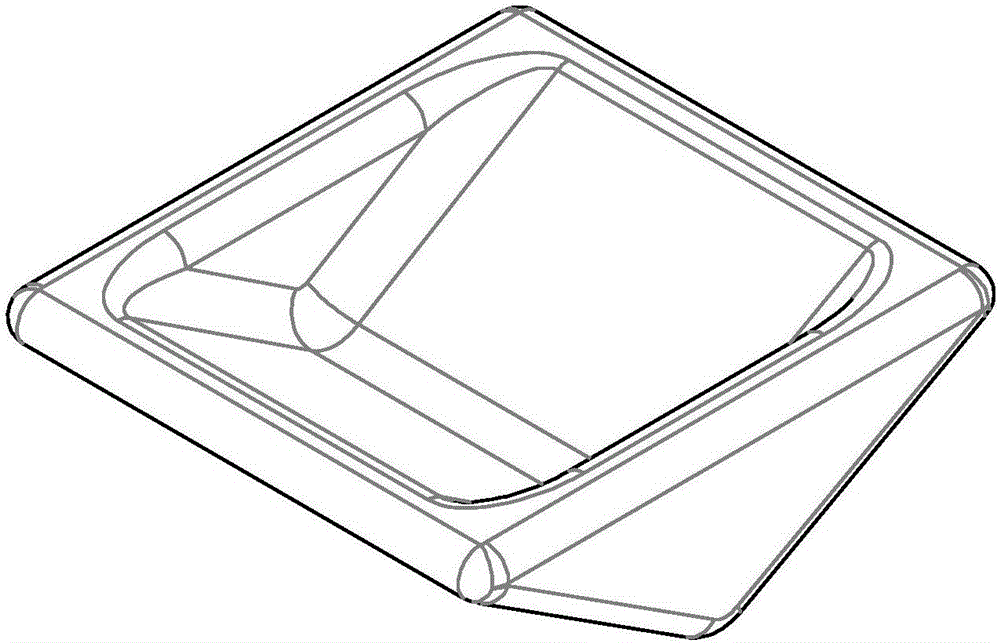

[0013] see Figure 1-Figure 3 , the processing flow of this specific embodiment is as follows: first, the blank is pre-forged into a hexagonal blank of a certain specification, and then the hexagonal blank is cut into a pre-forging blank 5; finally, the pre-forging blank 5 is put into the mold Extruded.

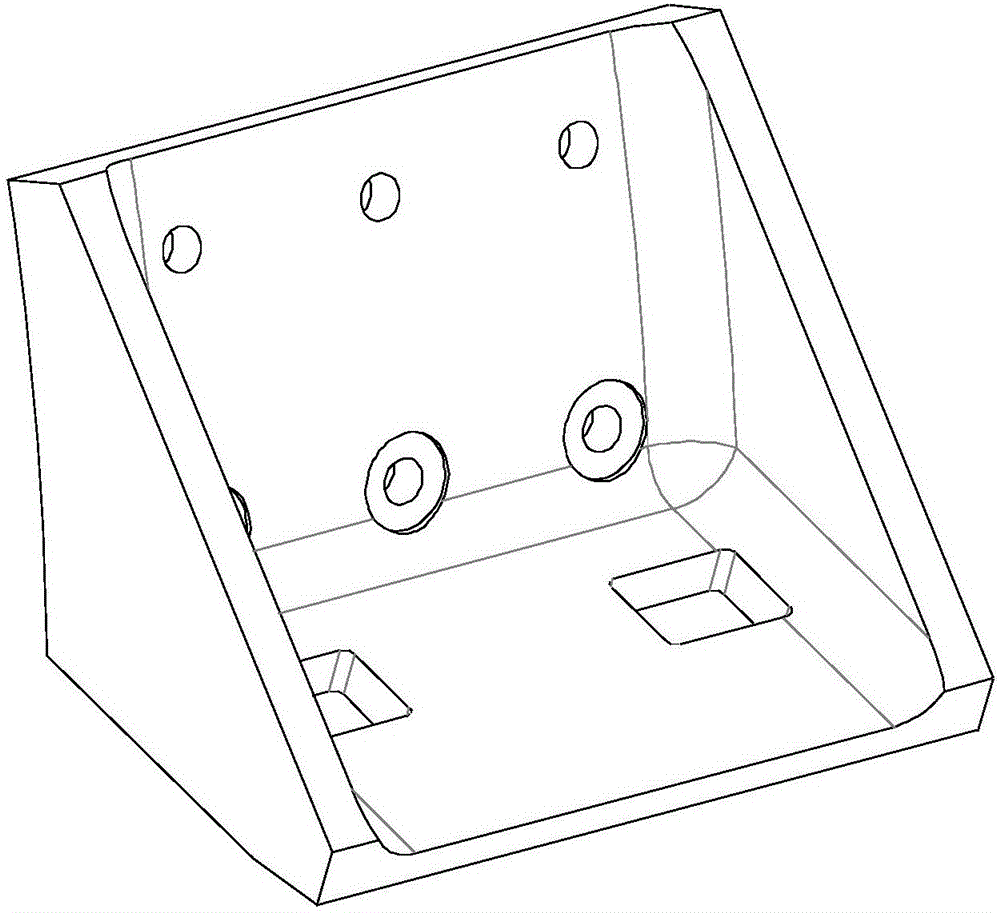

[0014] Further, the mold is composed of an upper anvil 1, a wedge 2, an upper mold 3, a guide rod 4, a lower mold 6, a fastening bolt 7, a push rod 8 and a lower mold base 9; the upper mold 3 The dovetail at its upper end is connected to the upper anvil 1 of the hydraulic press; a wedge 2 is provided between one side of the dovetail and the upper anvil 1, and the lower mold 6 is fixed on the lower mold base 9 by fastening bolts 7, and the guide The lower end of the rod 4 is fixed in the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com