Bobbin-yarn liquid-ammonium treating apparatus

A liquid ammonia treatment and liquid ammonia technology, which is applied in fiber treatment, liquid/gas/steam yarn/filament treatment, textiles and papermaking, etc., can solve the problem of low productivity of liquid ammonia finishing equipment, single yarn and skein strength drop, Problems such as narrow application range of equipment, to achieve the effect of improving dyeing rate and level dyeing, reducing unevenness of strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

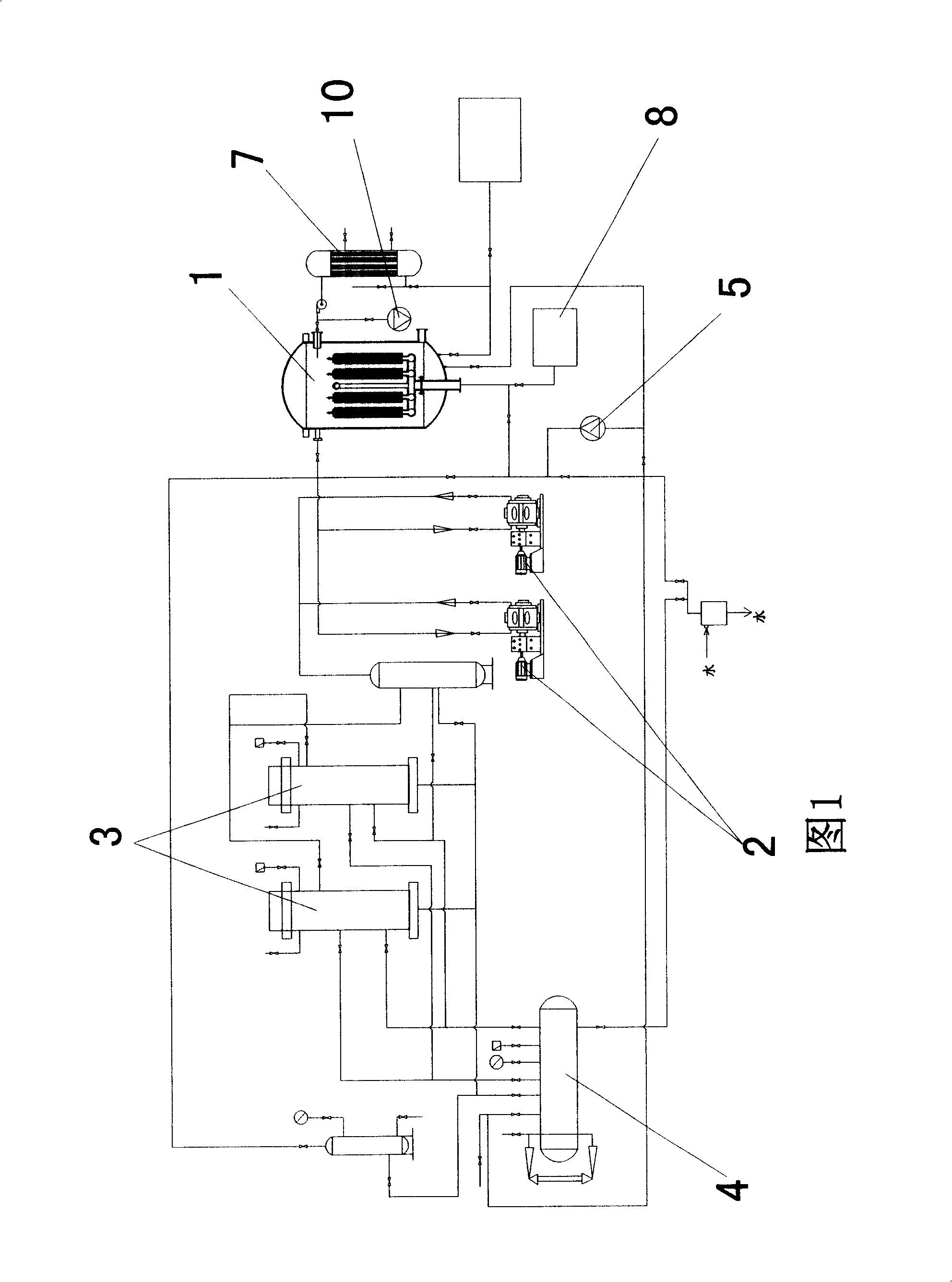

[0017] See Figure 1, figure 2 , the bobbin liquid ammonia treatment equipment of the present invention, its composition comprises: liquid ammonia treatment tank 1 and liquid ammonia supply device, ammonia gas heater 7, steam generator 8, tail gas absorption tower and vacuum pump 10 respectively connected thereto. The liquid ammonia supply device includes an ammonia compressor 2 , a condenser 3 , an ammonia storage device 4 and a liquid ammonia delivery pump 5 connected in sequence through pipelines.

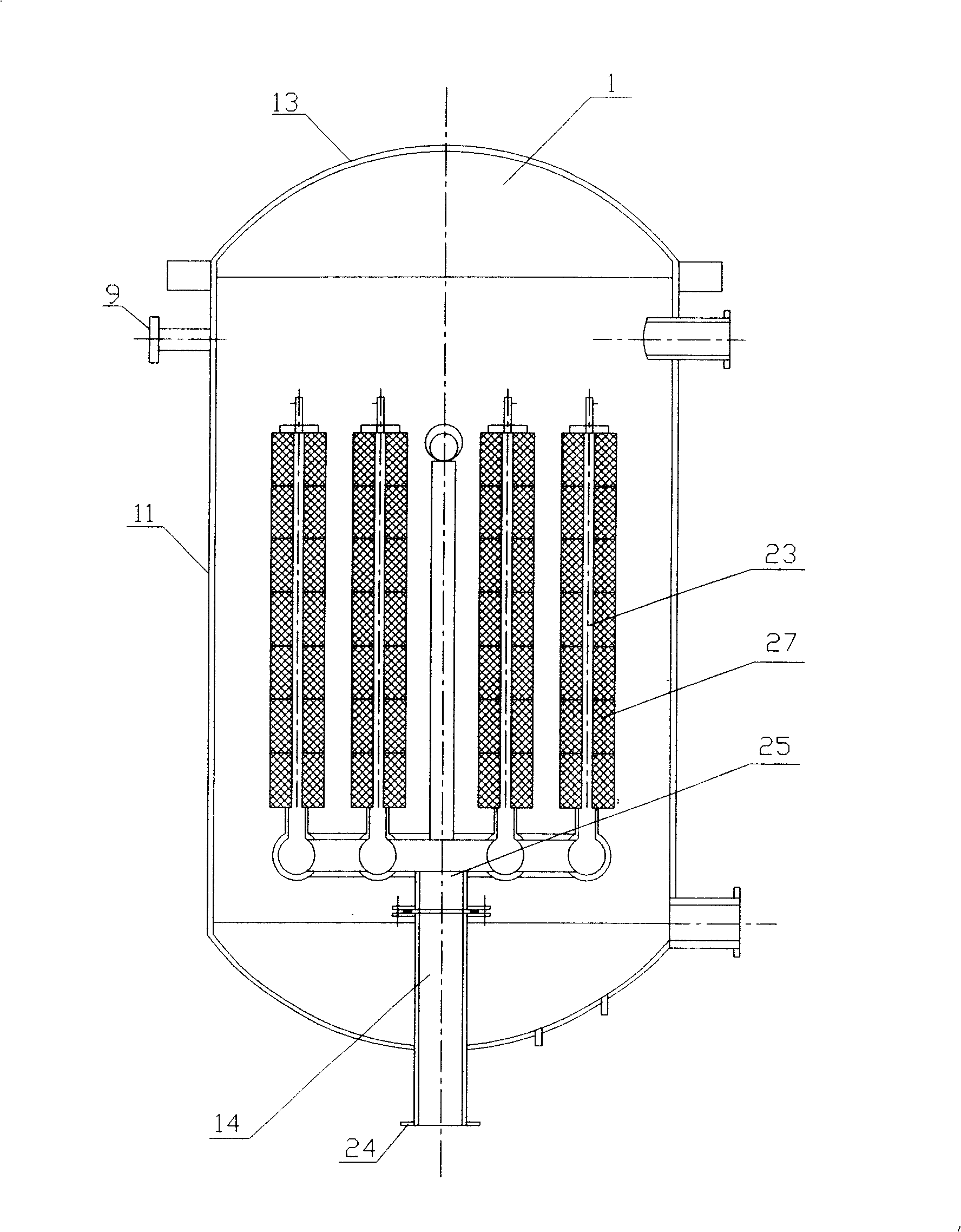

[0018] The liquid ammonia treatment tank 1 in the present invention can be horizontal or vertical, with a pressure bearing capacity of not less than 1-2.2 MPa, and can withstand a certain degree of vacuum. Both ends of the tank body 11 are equipped with pressure-bearing heads 13 or through flanges, the lower part of the tank body is provided with an inlet pipe 24 for liquid ammonia, and the upper part is provided with an outlet pipe 9 . The liquid ammonia treatment tank 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com