Hydrocracking catalyst and preparation thereof

A technology for catalyst and cracking activity, applied in the field of hydrocracking catalyst and its preparation, can solve the problems of low hydroconversion activity of hydrocarbon oil, etc., and achieve the effect of improved activity and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

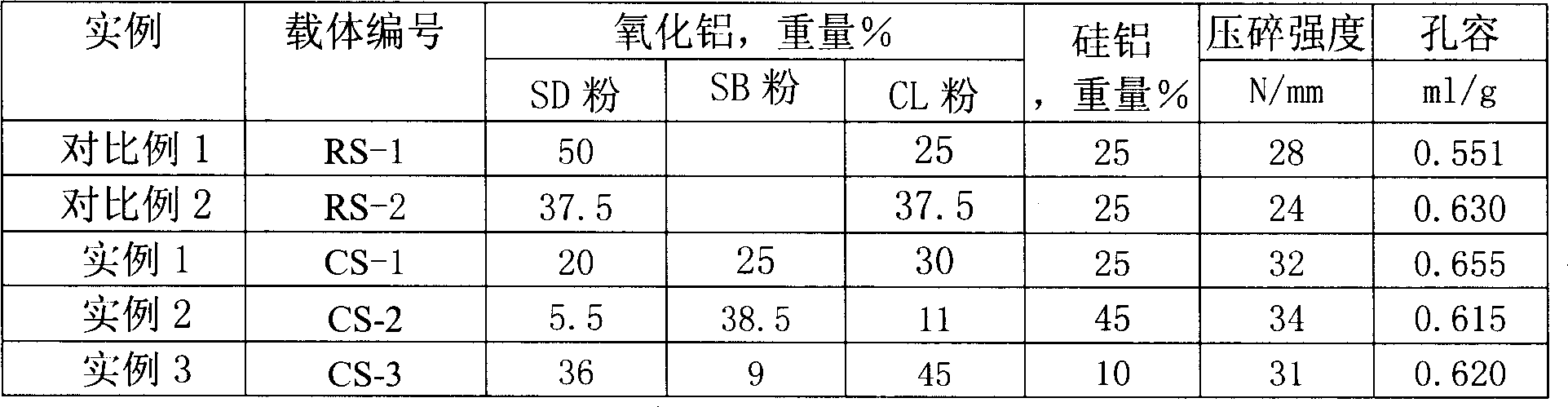

[0035] This example describes the preparation of the catalyst support of the present invention

[0036] Get 250g Y type molecular sieve (same as comparative example 1) with 227 gram SD powder (same as comparative example 1), 313 gram CL powder (same as comparative example 1), 268 gram SB (production of Sasol company, trade name SB, pore volume 0.53ml / g, dry basis 70%) powder, mixed with 30 grams of Selina powder, 750ml of aqueous solution containing 20ml of analytically pure nitric acid, extruded into a trefoil-shaped strip with a circumscribed circle diameter of 1.6 mm, dried at 120°C, and roasted at a temperature of 550°C After 3 hours, the carrier CS-1 was obtained. Table 1 shows the catalyst carrier composition, carrier crushing strength and pore volume.

example 2

[0038] This example describes the preparation of the catalyst support of the present invention

[0039] Get 250g Y type molecular sieve (same as comparative example 1) with 35 gram SD powder (same as comparative example 1), 64 gram CL powders (same as comparative example 1), 229 gram SB powders (same as example 1), 30 gram of Selina powder, Mix 750ml of aqueous solution containing 20ml of analytically pure nitric acid, extrude into trefoil strips with a circumcircle diameter of 1.6mm, dry at 120°C, and roast at 550°C for 3 hours to obtain carrier CS-2, catalyst carrier composition and carrier crushing The strength and pore volume are shown in Table 1.

example 3

[0041] This example describes the preparation of the catalyst support of the present invention

[0042] Get 250g of silica-alumina powder (Sasol produces the silica-alumina powder containing 40% of silicon oxide, trade name Sira-40, dry basis 80%) with 1091 gram of SD powder (same as comparative example 1), 1250 gram of CL powder (same as comparative example 1 ), 257 gram SB powders (with example 1), 1800ml contain the aqueous solution mixing of analytical pure nitric acid 55ml, extrude into the trefoil bar that circumscribed circle diameter is 1.6 millimeters, 120 ℃ of oven dry, roasting 6 hours under 450 ℃ of temperature, get Carrier CS-3, catalyst carrier composition, carrier crushing strength and pore volume are shown in Table 1.

[0043] Table 1

[0044]

[0045] The results given in Table 1 can illustrate that the crushing strength of the carrier provided by the present invention is obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com