Tobacco moistening through-flow hot blast drum method and apparatus

The technology of roller and hot air is applied in the field of tobacco leaf moistening, which can solve the problems of slow heating of tobacco leaves, uneven moisture content of tobacco leaves, low heat and moisture exchange intensity, etc., and achieves the effects of simple device structure, good leaf moistening effect and high leaf moistening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

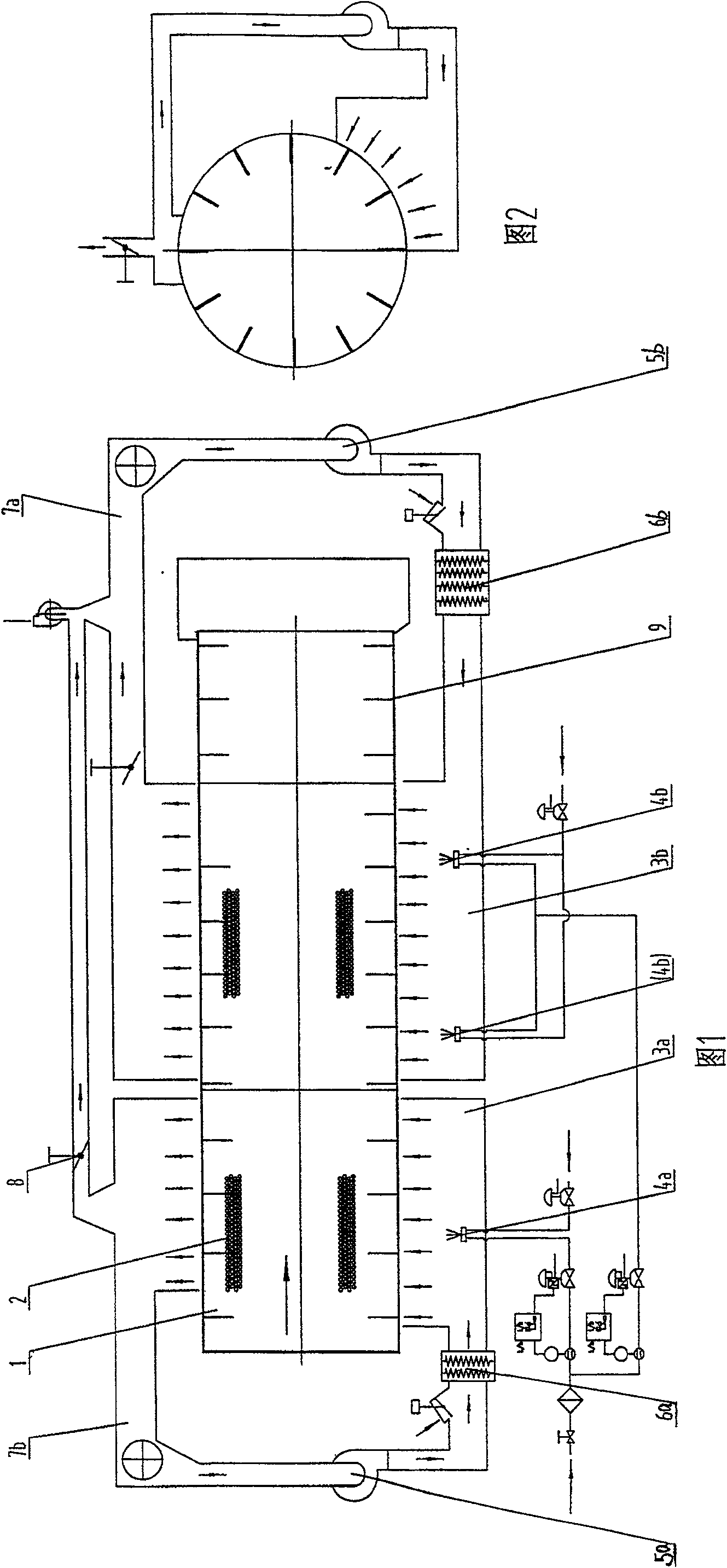

[0013] Such as figure 1 , figure 2 As shown, the leaf moistening device of the present invention mainly includes a horizontally arranged drum 1, which is preferably placed obliquely, and the feed end is slightly higher than the discharge end. Through holes 2 are uniformly opened on the drum. Set the front section of the drum as the heating section, and the rear section as the humidification section; or set the front section of the drum as the heating section, the middle section as the humidification section, and the rear section as the uniform material section; set it outside the heating section and the humidification section of the drum There are hot air devices 3a, 3b that send hot air into the drum along the radial direction of the drum and humidifiers 4a, 4b that apply moisture, but apply less water or steam to the heating section that mainly functions as pre-moistening and preheating tobacco leaves, so as to reduce the temperature of the tobacco leaves. Crushing, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com