Offshore buoyancy tank combination type adjustable fitting

A articulated joint and combined technology, which is applied in the direction of buoys, special-purpose vessels, ships, etc., can solve the problems of high operational strength, difficulty and danger, poor adaptability to sea wind and waves, and complex force on the articulated surface, so as to improve the overall The effect of bearing capacity, reducing the difficulty of assembly and operation risk, and simplifying the form of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

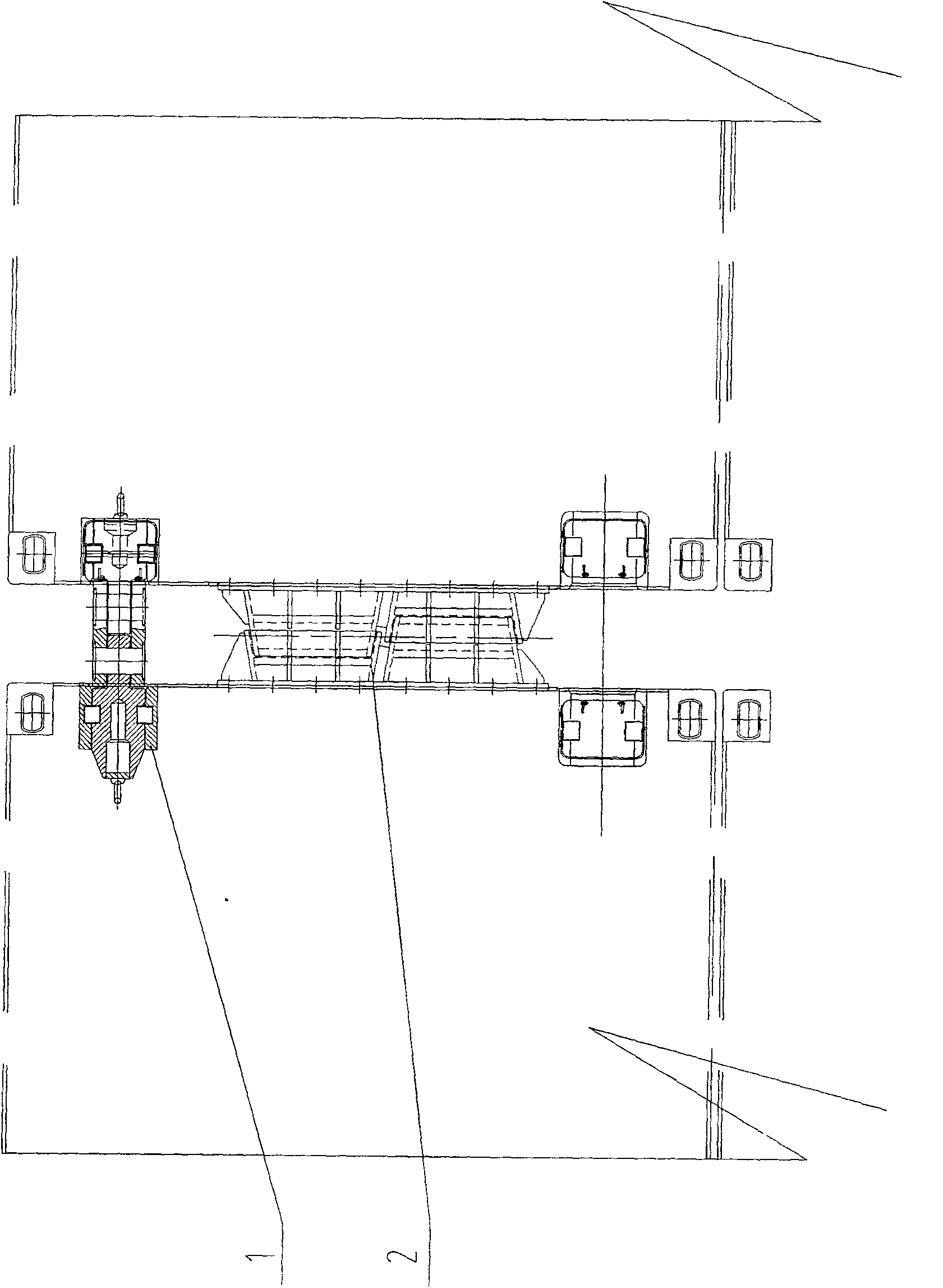

[0017] The two flexible connector seats are respectively welded at the ends of the two docked buoyancy tanks, and the shear force connector fixed on the connector A seat and the connector B seat are respectively welded at the ends of the two docked buoyancy tanks, as figure 1 As shown, the flexible connector 1 and the shear connector 2 are connected to two docked buoyancy tanks.

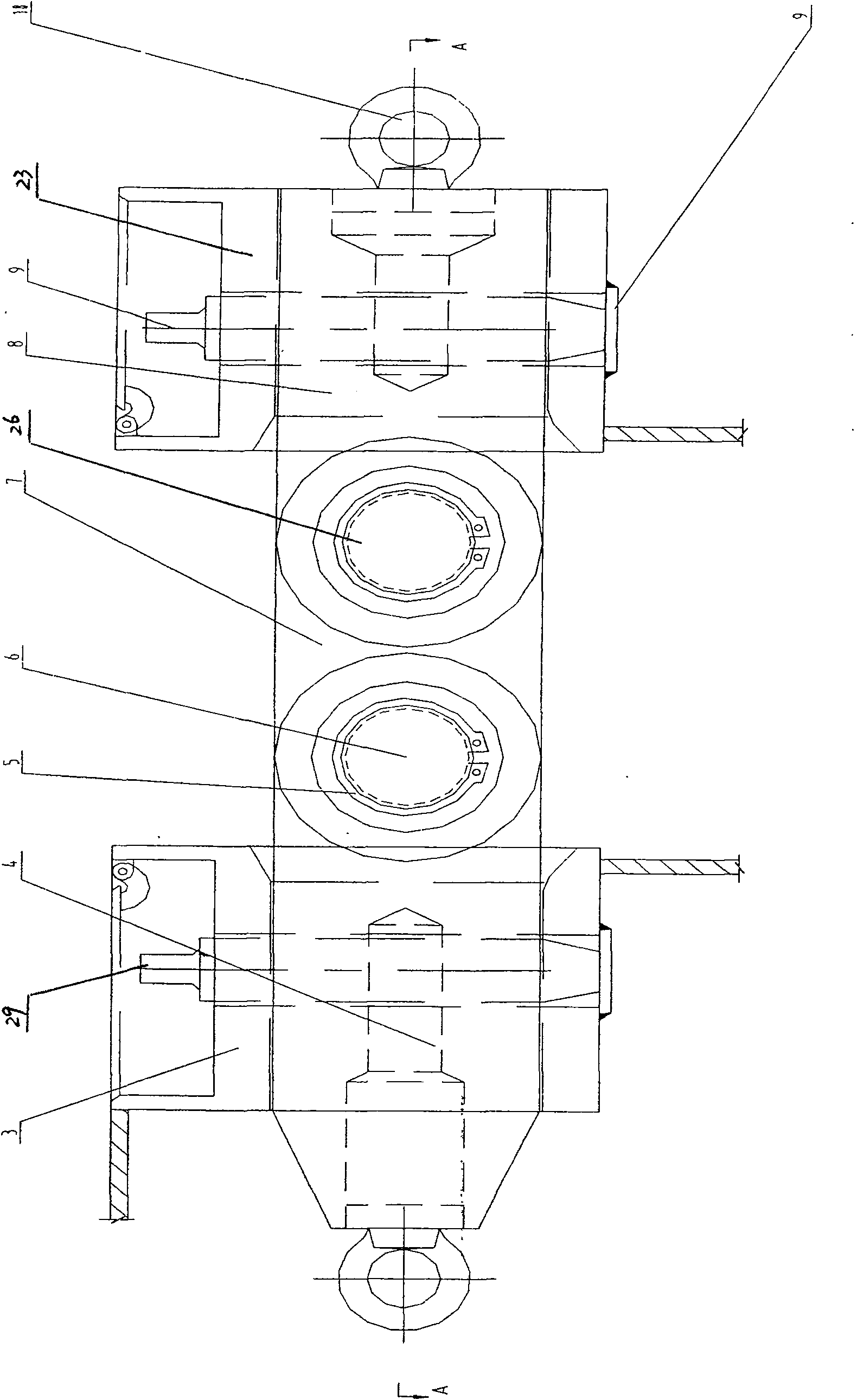

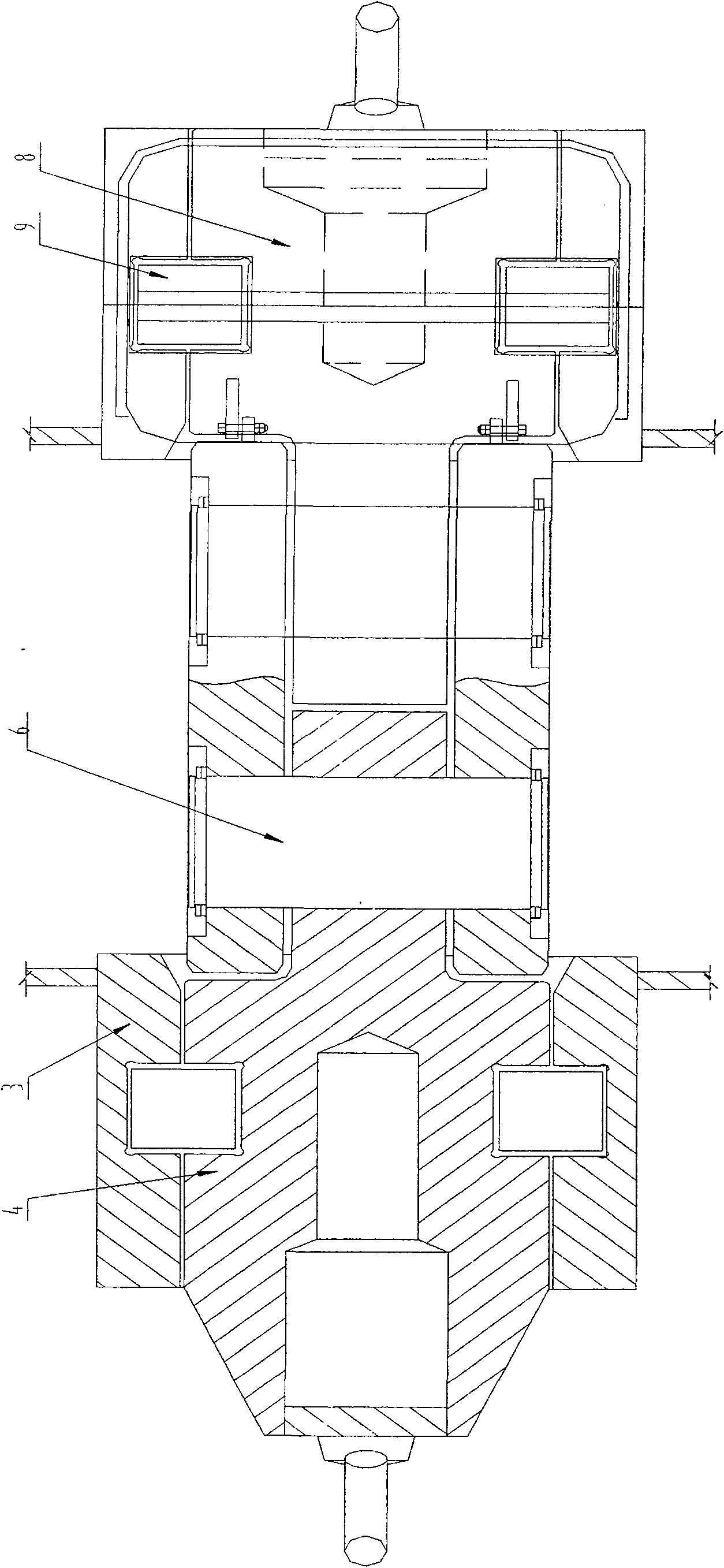

[0018] Such as figure 2 As shown, the flexible connector consists of two flexible connector seats 3 and 23, a long single ear slider 4, a short single ear slider 8, a long single ear connecting shaft 6, a short single ear connecting shaft 26, and a connecting plate 7 , the shaft is composed of a circlip 5, gate pins 9 and 29, and eyebolt screws 10; the two ends of the flexible connector seat are provided with openings for inserting and withdrawing gate pins, and gate pins 9 and 29 enter thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com