Coating device and coating method

A coating device and coating technology, which is applied in the direction of surface coating liquid devices, coatings, electrical components, etc., can solve problems such as difficult coating, damage or deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described below with reference to the drawings.

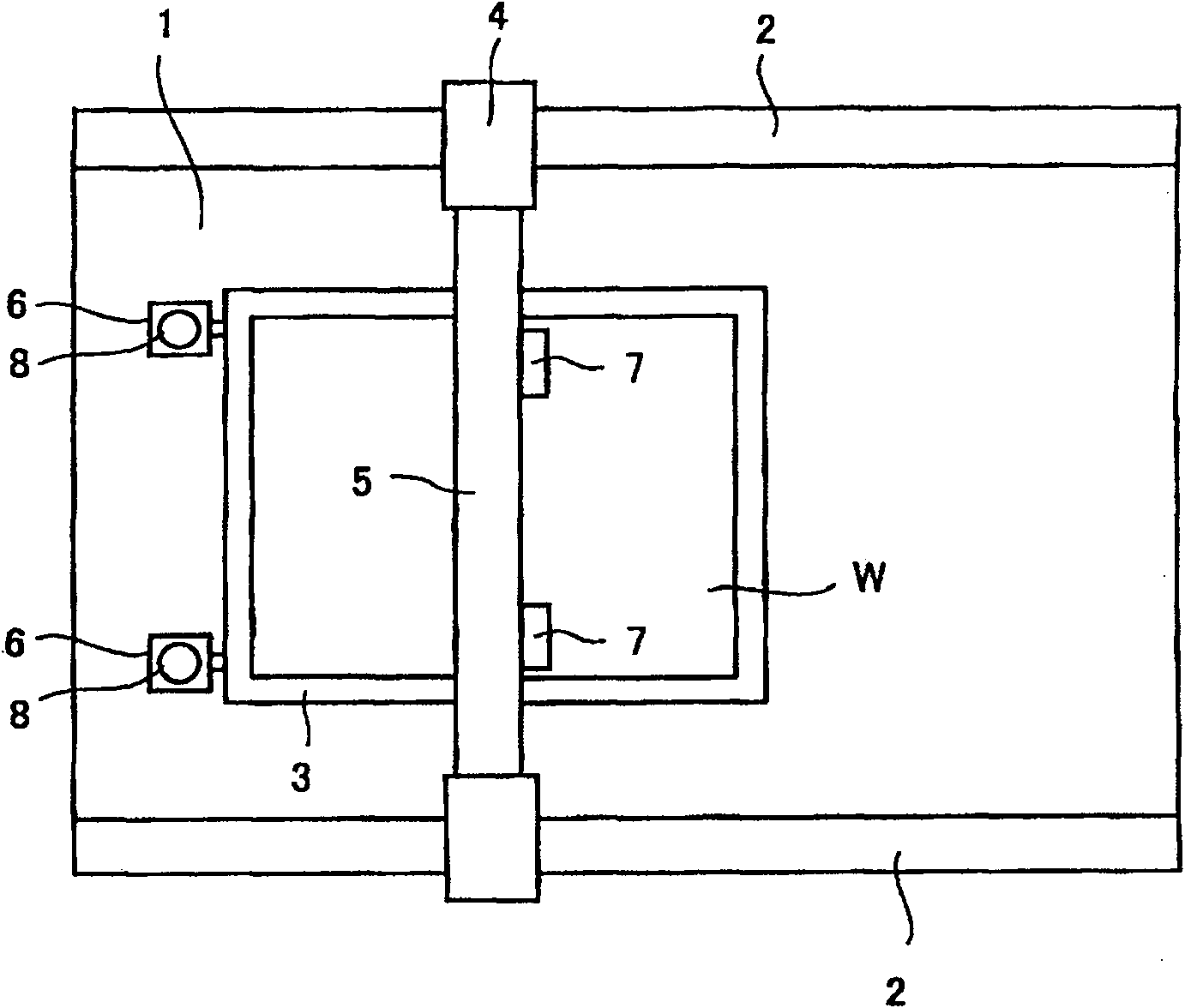

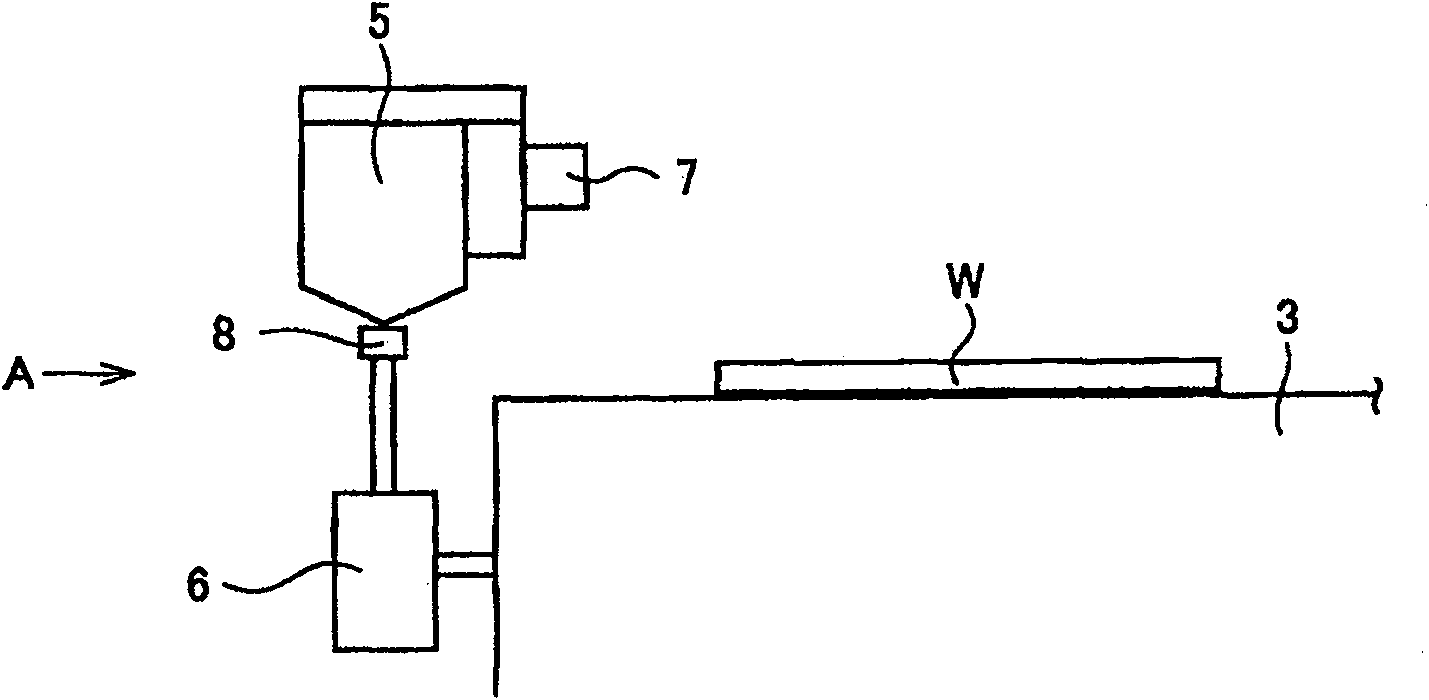

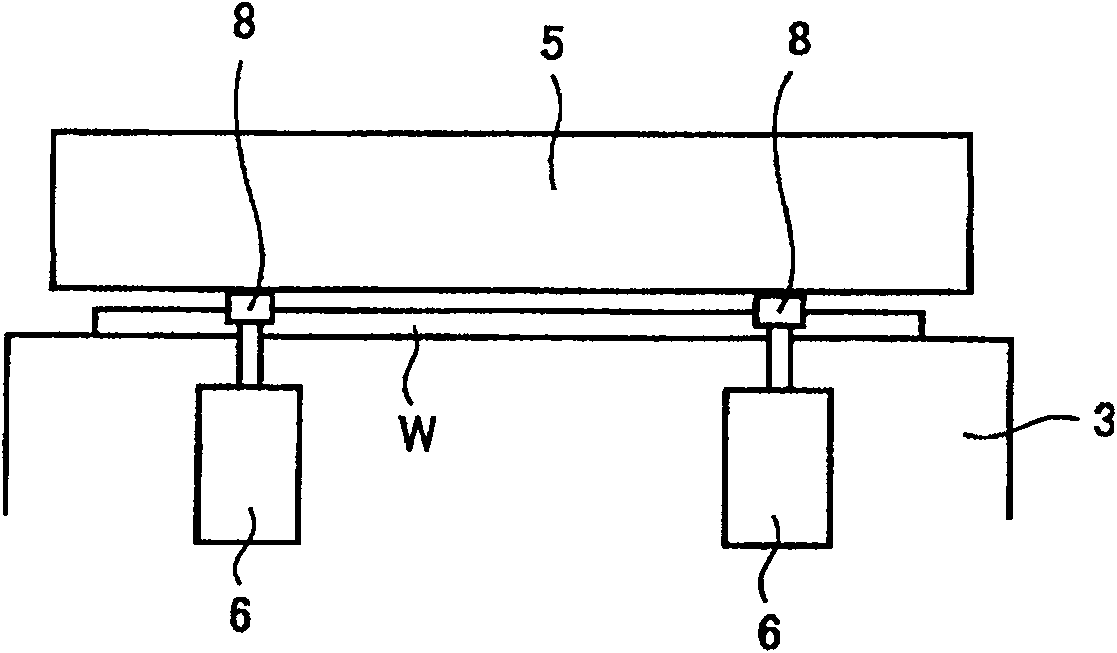

[0037] figure 1 It is a plan view showing one embodiment of the coating device according to the present invention, figure 2 yes figure 1 side view of the main part, image 3 yes figure 2 A-direction view.

[0038] In the substrate coating apparatus of this embodiment, if figure 1 As shown, a pair of parallel guide rails 2 and 2 are provided on the base 1 , and a substrate placing part 3 for placing a substrate W is fixed at the middle position of the guide rails 2 and 2 , that is, the center of the surface of the base 1 . In addition, the gate-shaped moving mechanism 4 straddles the substrate placement portion 3 and is movably installed between the guide rails 2, 2, and the slit nozzle 5 is attached to the gate-shaped moving mechanism 4 via a lifting device.

[0039] In addition, in the present embodiment, in particular, in the substrate placement unit 3, reference jig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com