Method of manufacturing a curved measuring tube for a vibratory measurement sensor

A measurement sensor, bending measurement technology, applied in the direction of measuring flow/mass flow, measuring device, direct mass flowmeter, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

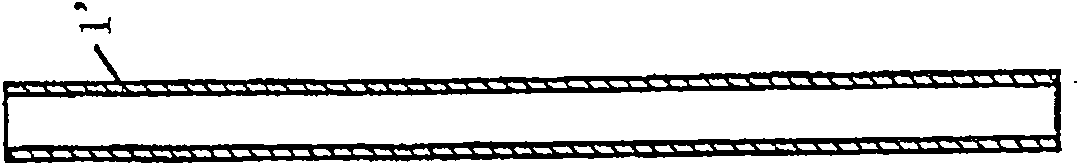

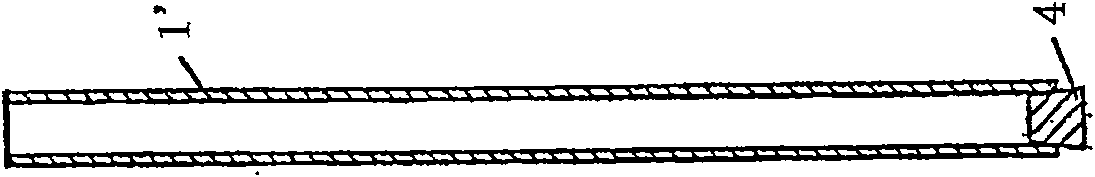

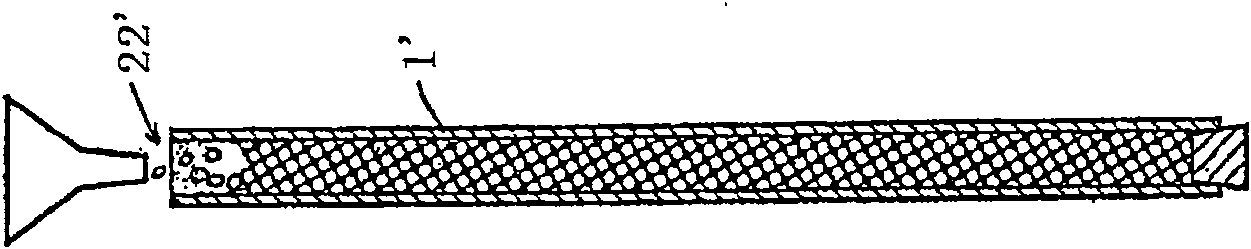

[0057] Figures 1 to 5 An in particular straight initial tube 1' with a predetermined in particular circular cross-section and an inner cavity is shown in side view, respectively. The initial tube 1' is to be transformed into a curved initial tube 1" having a predeterminable spatial shape by suitably introducing at least partly a bending force acting on it from the outside. Then as Figure 11 As shown, the bent initial tube 1 ″ is later used as a measuring tube 10 of the vibrating type, for example a measuring tube 1 of a Coriolis mass flow measuring sensor.

[0058] Before starting the actual deformation process, an initial tube 1' having a desired length L may be cut, for example, from a piece of tubular rod (not shown). The length L of the initial tube 1' is simply derived from the desired length of the initial tube 1" bent after bending. The initial tube 1' has a predetermined inner diameter dI and can be made of materials normally used for measuring tubes of said ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com