Coating mechanism and coating method, defect correction device and defect correction method

A coating and defect technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of poor operation convenience and less ink, and achieve the effect of easy coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] (Embodiment 1)

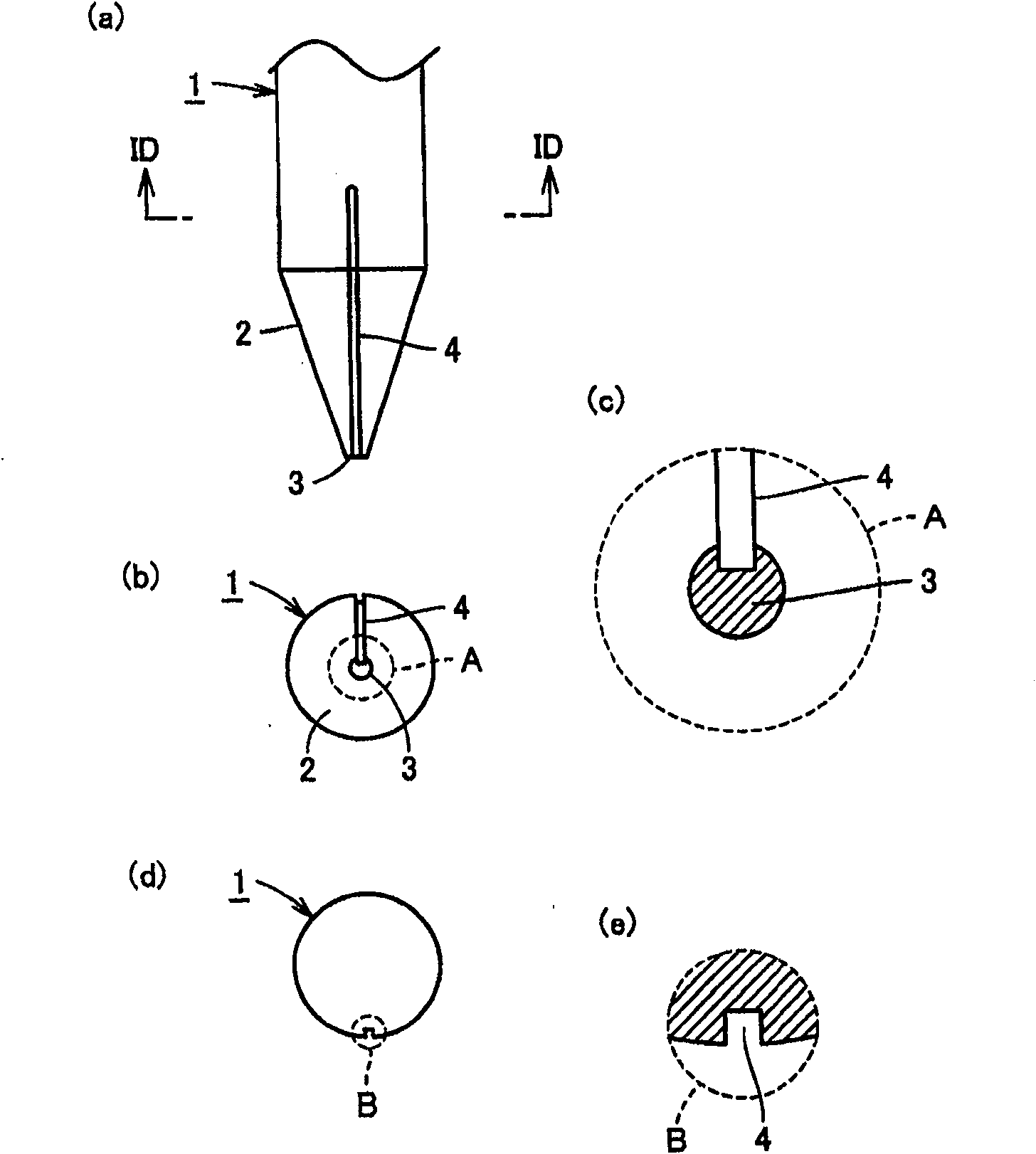

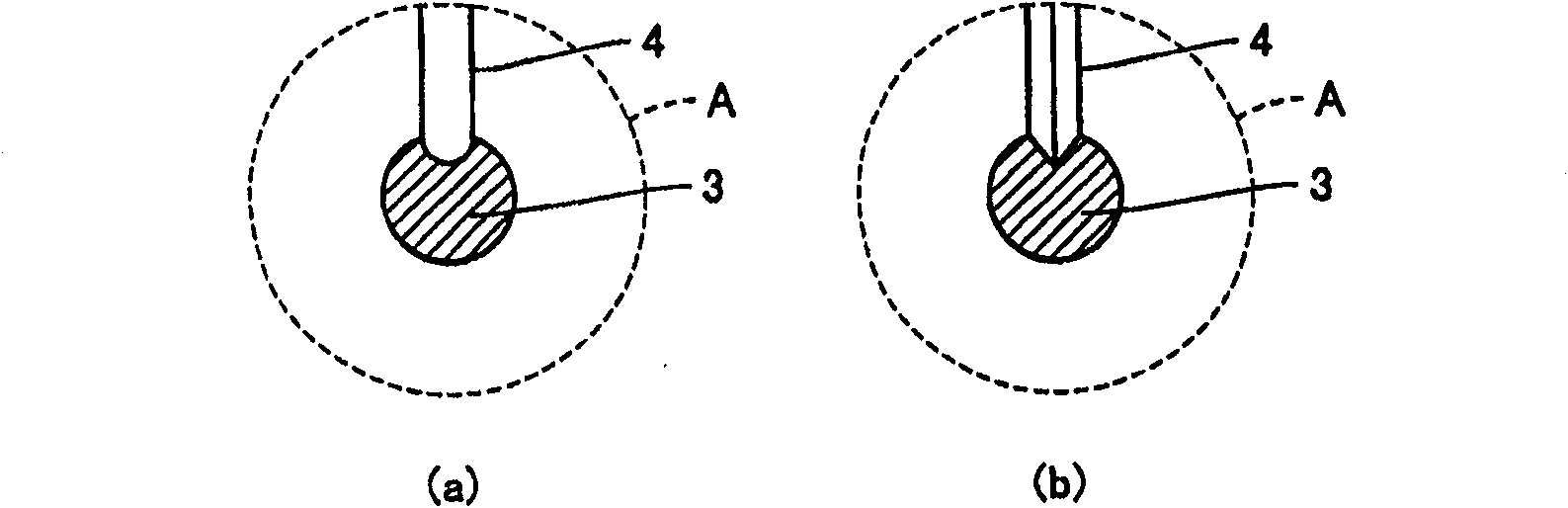

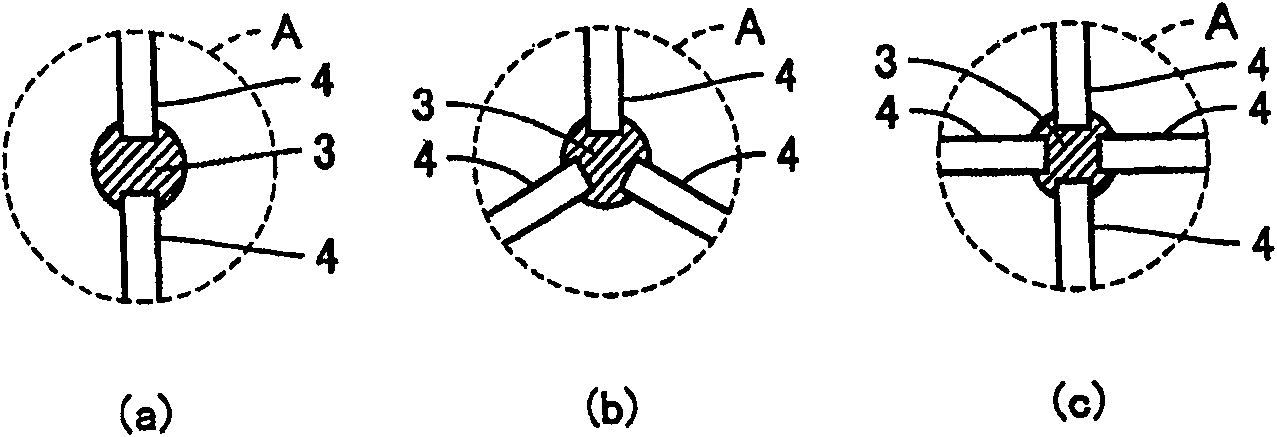

[0107] figure 1 (a) is a front view showing the tip portion of the applicator needle 1 according to Embodiment 1 of the present invention, figure 1 (b) is its bottom view, figure 1 (c) is figure 1 Enlarged view of part A of (b), figure 1 (d) is figure 1 (a) ID-ID line sectional view, figure 1 (e) is figure 1 Enlarged view of part B of (d).

[0108] exist figure 1 In (a) to (e), a tapered part 2 is provided at the front end of the coating needle 1, and the tapered part 2 makes the cross-sectional area of the coating needle 1 from The front end of the application needle 1 gradually expands toward the base end, and a flat surface 3 is provided at the front end of the application needle 1, and on the outer peripheral surface of the front end of the application needle 1, a predetermined dimension is formed from the front end to the upper part of the tapered part 2. slot 4.

[0109] In this way, by providing the tapered portion 2, the flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com