Coating device

A coating device and coating technology, applied in the direction of spraying devices, spraying devices, devices for coating liquid on surfaces, etc., can solve the problems of high manufacturing costs, and achieve the effects of low manufacturing cost, small size, and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

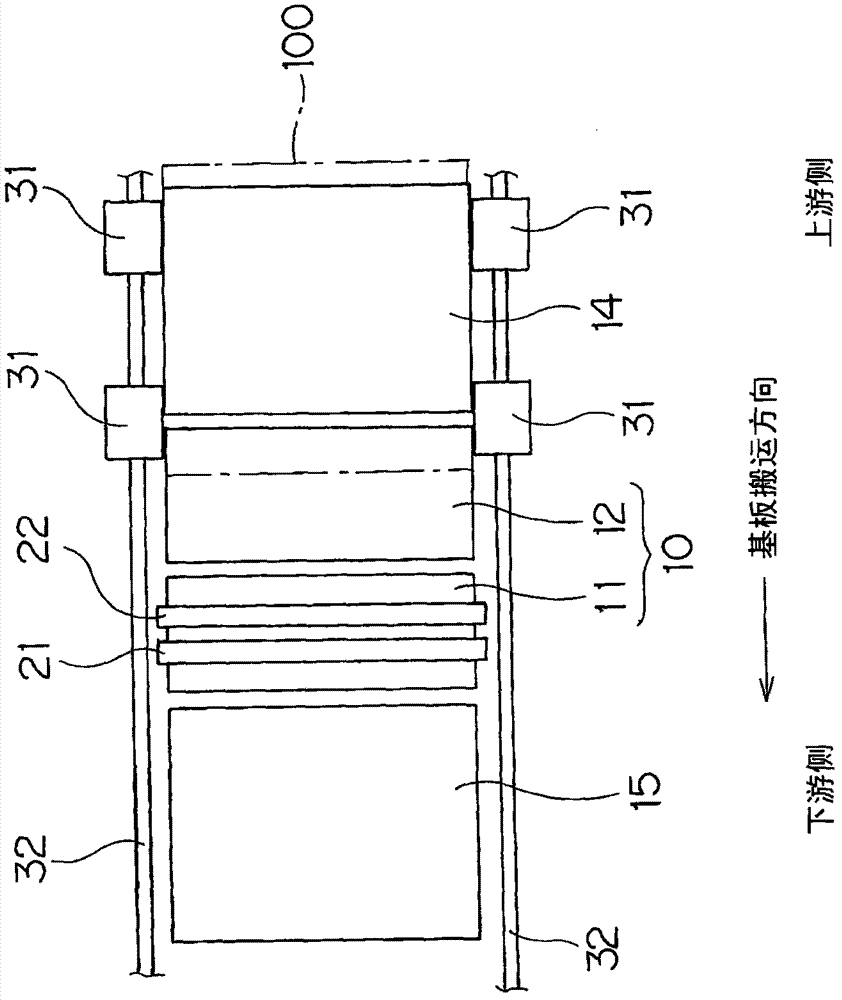

[0041] Embodiments of the present invention will be described below based on the drawings. figure 1 It is a schematic plan view of the coating device according to the first embodiment of the present invention.

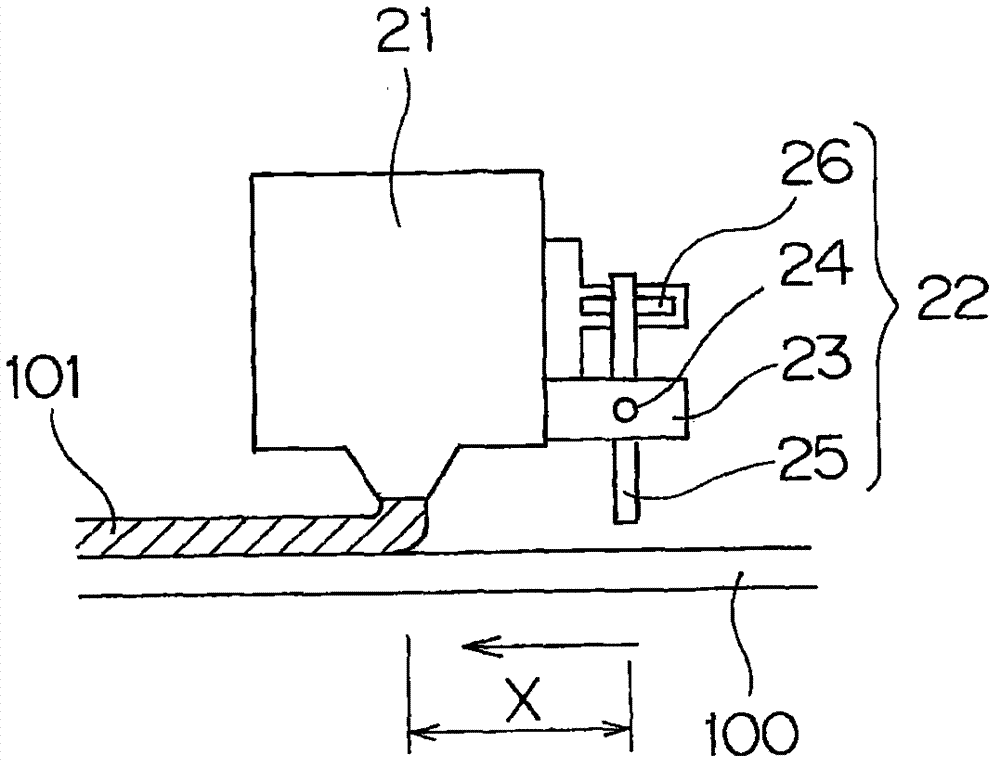

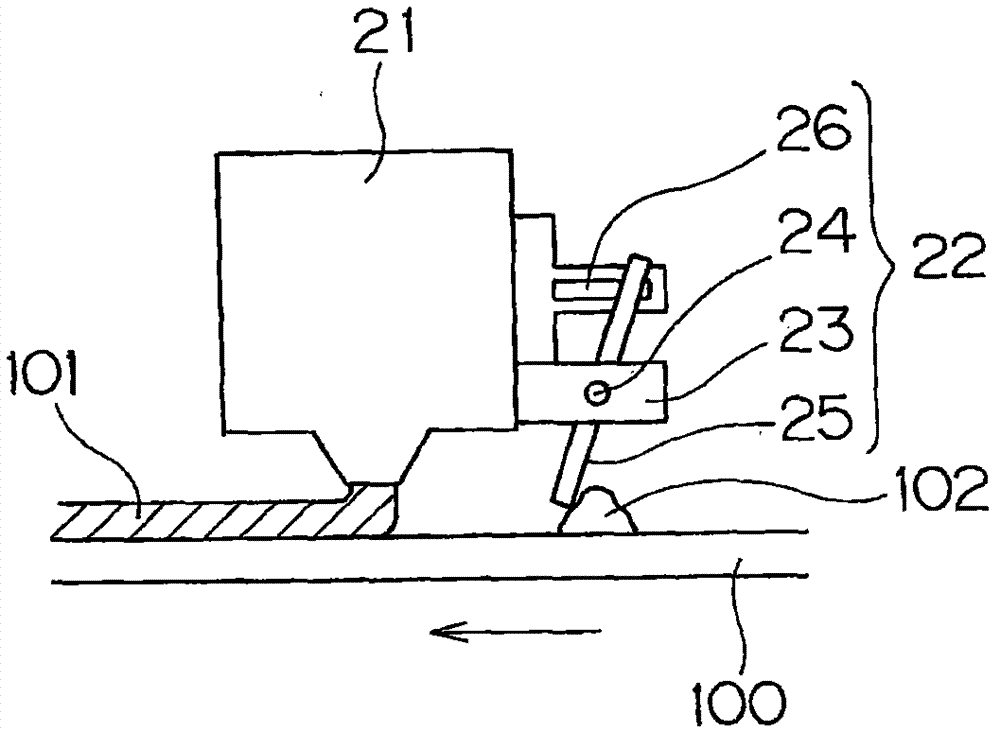

[0042] This coating device is a device for applying a coating liquid to the surface of the substrate 100 by moving the substrate 100 in one direction in a state where the substrate 100 is floated by supplying gas to the lower surface of the substrate 100 . This coating device has: a coating nozzle 21 which applies a coating liquid to the surface of the substrate 100 moving in one direction; On the upstream side of the substrate 100, foreign matter present on the surface of the substrate 100 is detected. In addition, air is used as the gas. However, a gas other than air, such as an inert gas such as nitrogen, may be used.

[0043] In addition, this coating apparatus has: a pair of floating tables 14, 15, which is formed with a discharge port for spraying gas to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com