Regenerated lead acid batteries and method

A lead-acid battery, acid battery technology, applied in lead-acid batteries, battery recycling, secondary battery charging/discharging and other directions, can solve the problems of accelerated corrosion and aging of positive plates, short battery life, environmental pollution, etc. Raw materials, prolonging service life, and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

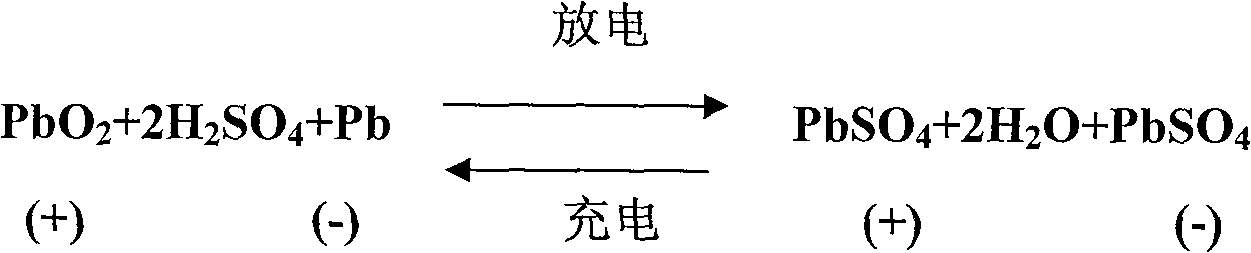

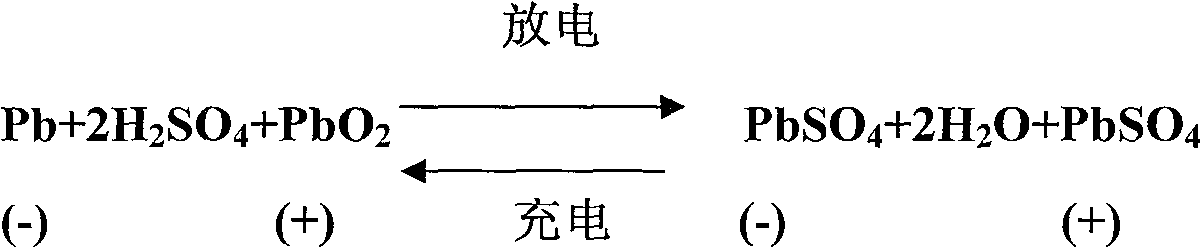

Method used

Image

Examples

Embodiment 1

[0017] The 1600AH lead-acid battery of Huaneng Xindian Power Plant has been used for 10 years and the battery capacity has been reduced to 90% of the rated capacity. This method is used for regeneration:

[0018] (1) Put the capacity of the battery to 0 volts before connecting the positive and negative poles interchangeably;

[0019] (2) When the battery capacity reaches 90% of the rated value, exchange the positive and negative poles;

[0020] (3) Charge with the rated capacity of the battery at a rate of 10 hours;

[0021] (4) When the charging voltage reaches the rated value, it is stable for 3 hours.

[0022] After regeneration, its capacity is restored, and as a result, the lead-acid battery has been used for another 10 years, and the battery capacity is still 100%.

Embodiment 2

[0024] After 2 years of use for lead-acid batteries for electric bicycles, the driving mileage is less than half of the rated capacity, and the battery capacity is less than 60% of the rated capacity. Use this method to regenerate:

[0025] (1) Put the capacity of the battery to 0 volts before connecting the negative electrodes interchangeably;

[0026] (2) When the battery capacity reaches 60% of the rated value, exchange the positive and negative poles;

[0027] (3) Charge with the rated capacity of the battery at a rate of 10 hours;

[0028] (4) When the charging voltage reaches the rated value, it is stable for 5 hours.

[0029] After regeneration, its capacity was restored, and it was used for another 2 years, and the effect was obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com