Method for automatically adjusting silicon wafer grinding pressure of chemical-mechanical polisher

A chemical mechanical and automatic adjustment technology, which is applied in the direction of grinding/polishing equipment, grinding devices, grinding machine tools, etc., can solve the problems of lack of stability in the process, changes in the pressure deformation of the grinding pad, etc., to prevent fluctuations in speed and improve stability Sexuality and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

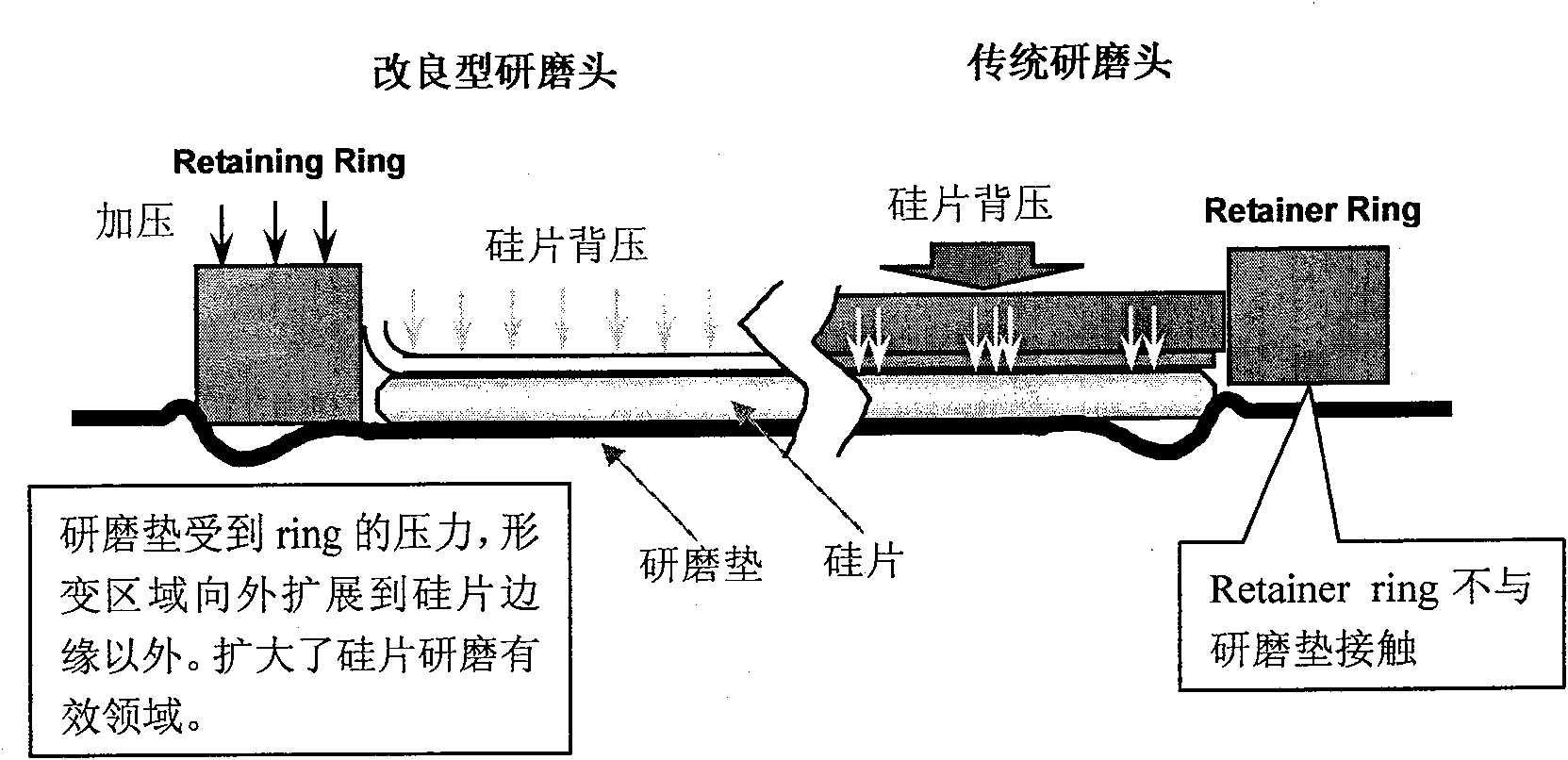

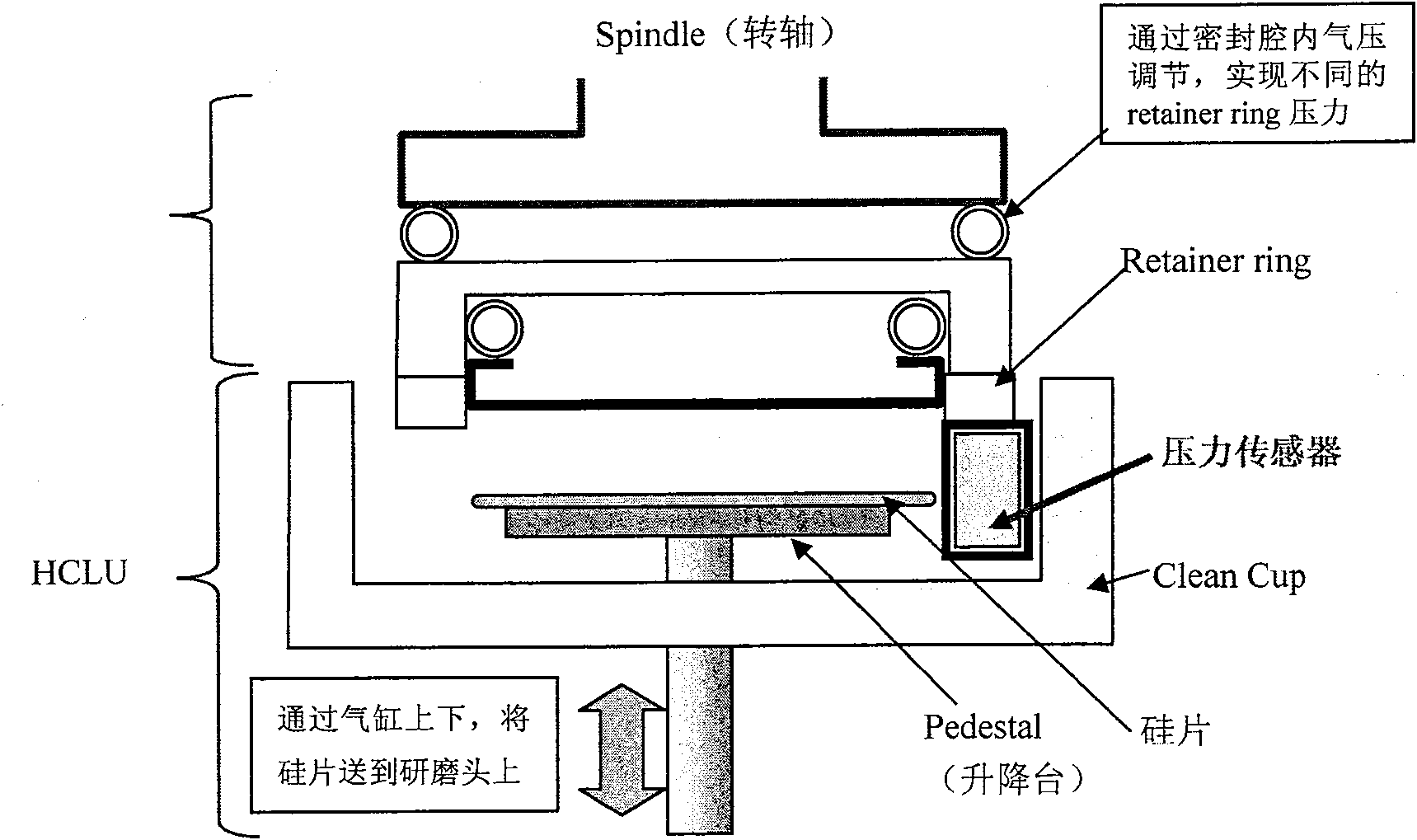

[0009] The HCLU (Head Clean Load / Unload) of the existing general-purpose Mirra CMP equipment mainly undertakes the functions of loading / unloading silicon wafers and cleaning the grinding head. The principle of the method of the present invention is: in order to realize the function of automatically measuring the thickness of the retainer ring, a pressure sensing sensor is firstly installed in the above-mentioned HCLU. When the grinding head is cleaned each time, the thickness of the ring at that time is calculated by the pressure value exerted by the retainer ring on the sensor. According to this thickness, during the actual grinding of the silicon wafer, corresponding compensation adjustments are made to the original set pressure value (need to modify the existing equipment control software) to ensure that the pressure on the grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com