LED light projector image forming apparatus

An imaging device and LED lamp bead technology, which is applied in the field of optoelectronics, can solve problems such as damage, high temperature of other lamp beads, and short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

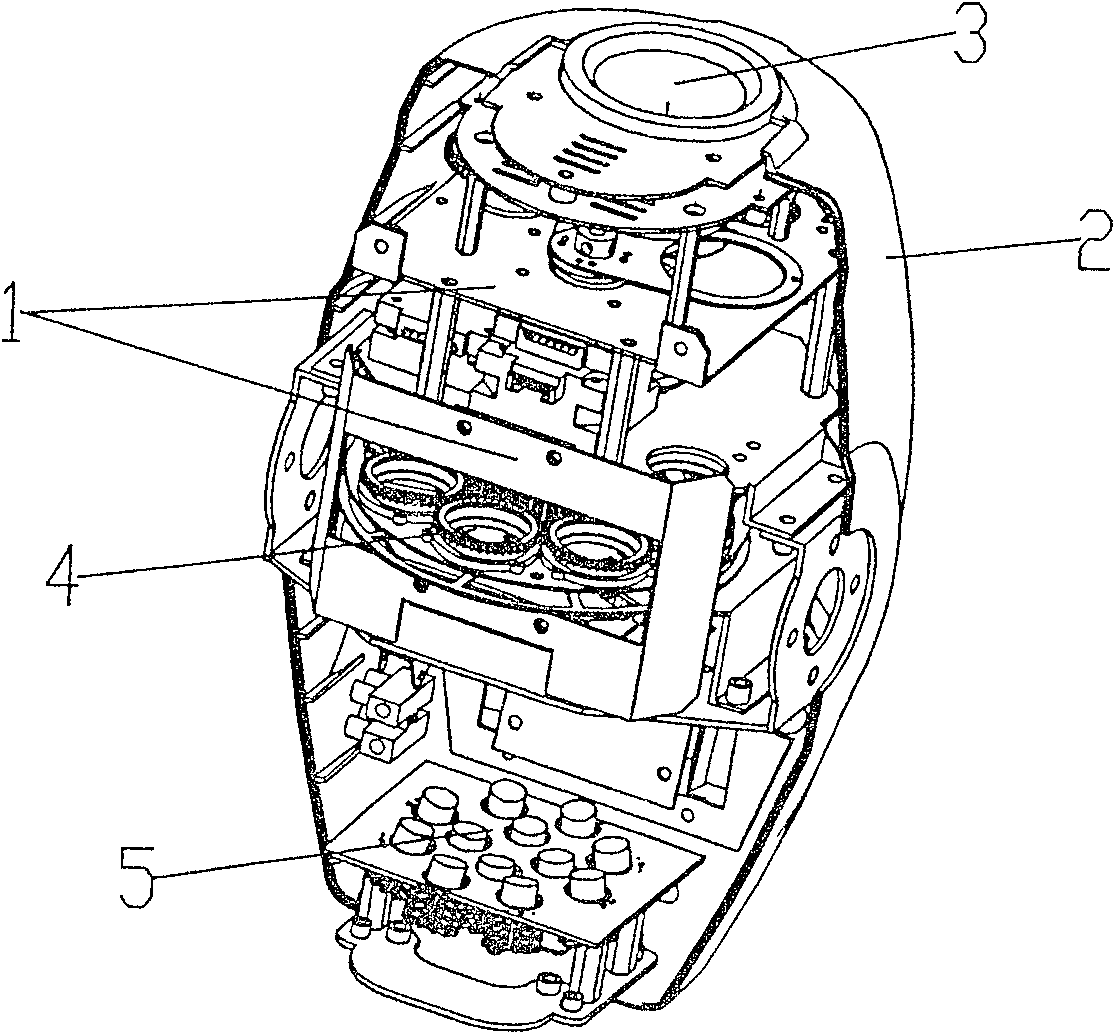

[0029] The LED projection light imaging device of the present invention will be further described below in conjunction with the accompanying drawings:

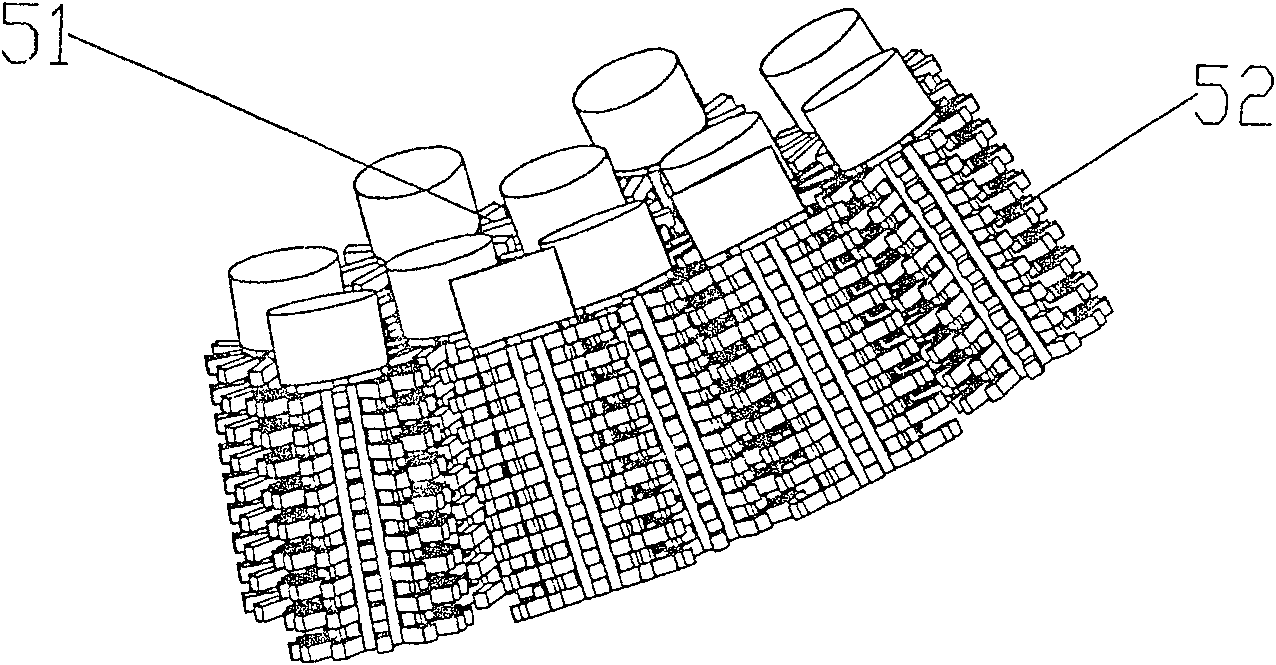

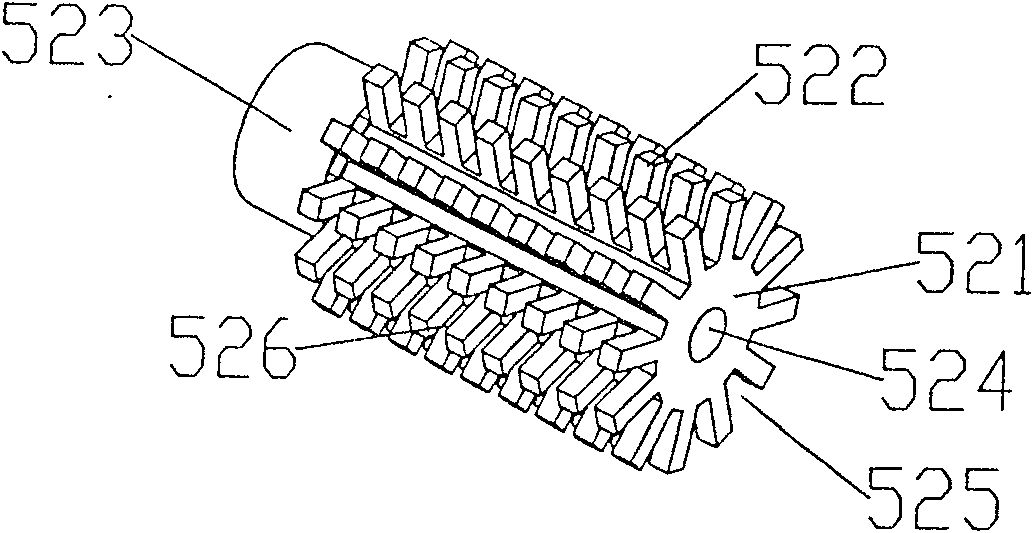

[0030] Such as figure 1 , figure 2 , image 3As shown, the LED projection imaging device of the present invention includes a bracket 1, a housing 2 and an imaging system 3, a rotating disk 4, and a light source 5 arranged in sequence. The imaging system 3 and the rotating disk 4 are installed on the bracket 1. The bead group 52 is arranged according to the shape of the concave surface 51 , and the light-emitting end of each LED lamp bead faces the inner side of the concave surface 51 and points to the focus of the concave surface 51 . The light-emitting end of each LED light bead points to the focus of the concave surface 51 , which means that it is facing the focus or is exactly in focus. The concave surface 51 is a spherical or parabolic curved surface. Each LED lamp bead is provided with a heat dissipation structure, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com