Oven system provided with displaceable sluice chamber

A technology of locking chamber and vacuum chamber, which is applied in the field of material furnace system, can solve the problems of increasing investment cost and achieve the effect of reducing the installation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

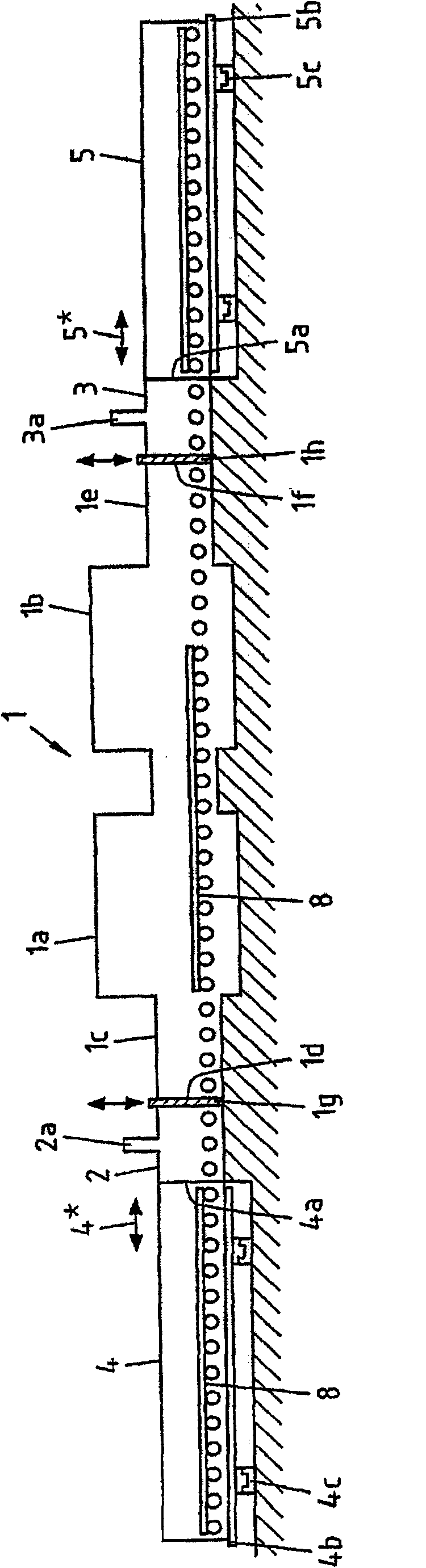

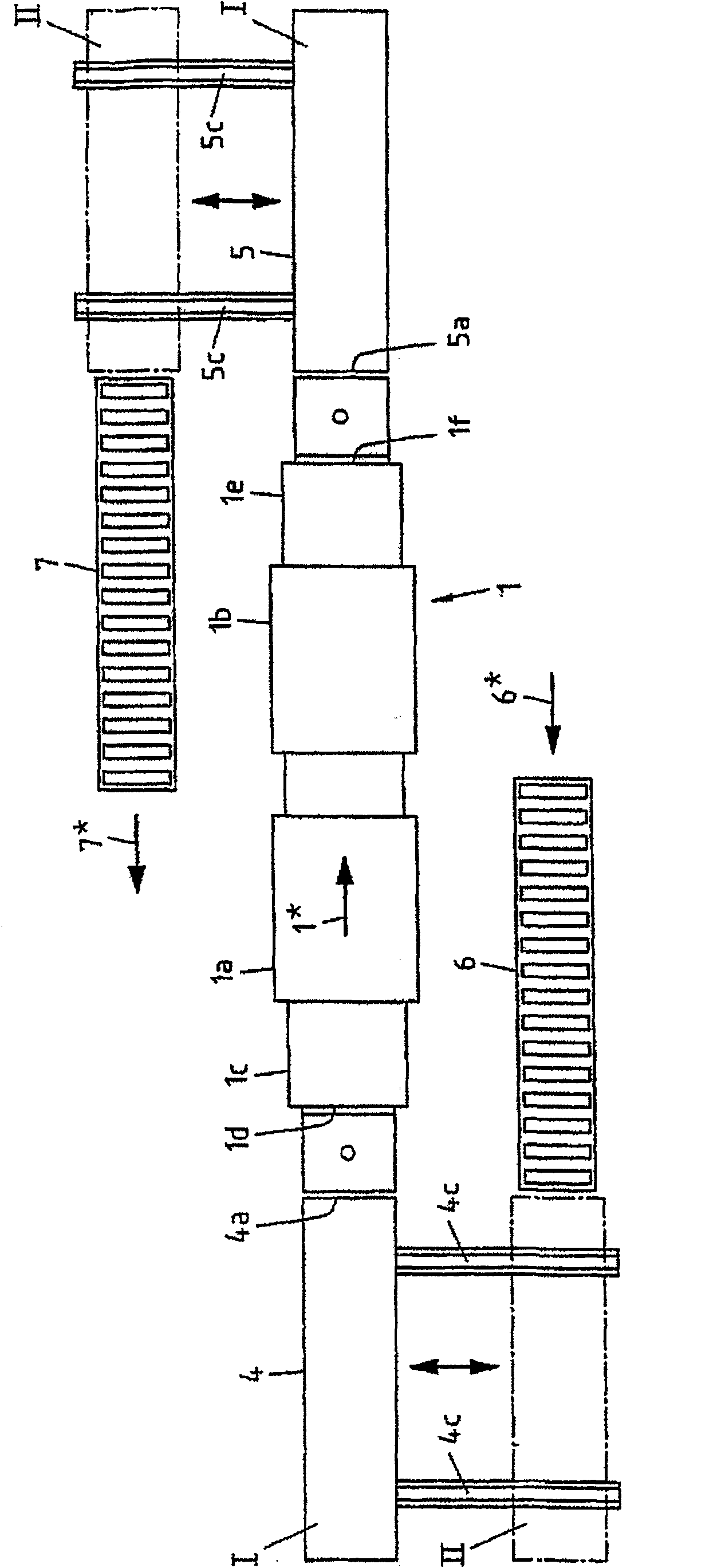

[0014] figure 1 The furnace system in includes a furnace 1 for heat treatment of elongated materials, in particular copper tubes 8, which is symmetrically designed and constructed as a roller hearth furnace and has a heating section 1a and a cooling section 1b. From figure 2 As can be seen in , the copper tube 8 travels through the furnace from left to right, so that the copper tube 8 is first heat treated and then cooled in a controlled manner. Before the heating section 1a, the furnace 1 has an input space 1c with a feed opening 1d, which is preferably closed in an airtight manner with a sliding door 1g. According to the symmetrical structure of the furnace 1, in the direction of travel, after the cooling section 1b, the furnace 1 has an output space 1e with an outlet opening 1f, in the same way as the input space 1c, preferably in an airtight manner with a sliding door 1h To close the discharge port 1f.

[0015] Before the feed opening 1d and after the discharge opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com