Clamping mechanism

A technology of clamping and template, applied in the field of clamping mechanism, can solve the problems of troublesome installation and long clamping mechanism, and achieve the effects of easy installation and transportation, long service life and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

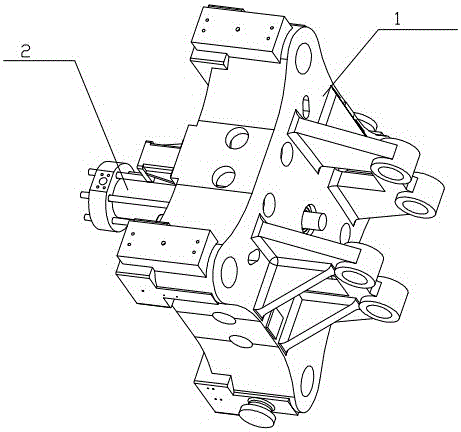

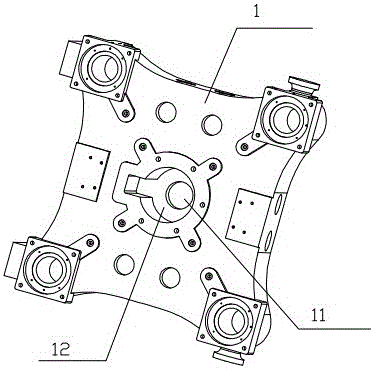

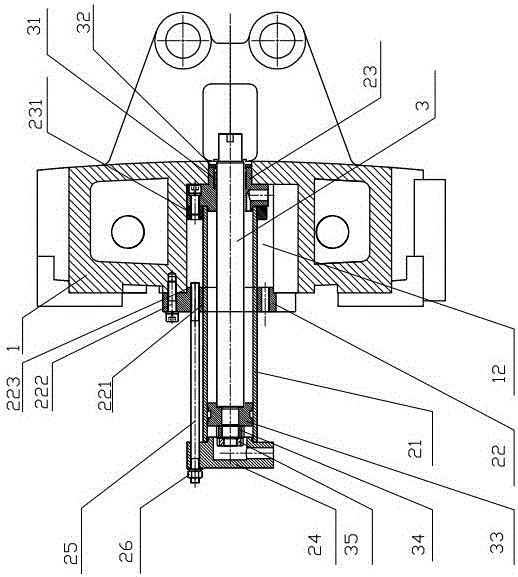

[0019] Depend on figure 1 combine figure 2 , 3 As shown, a mold clamping mechanism includes a mold adjusting template 1 and an oil cylinder 2. The mold adjusting template 1 is provided with a mold locking hole 11, and the rear surface of the mold adjusting template 1 is sunken inward to form an accommodating groove 12. , the cylinder 2 is provided with a mold clamping link 3 passing through the clamping hole 11 to be connected with the moving template, and the cylinder 2 is inserted into the accommodating groove 12 from the rear surface of the mold adjusting template 1 and It is fixed to the rear surface of the mold adjusting template 1 (with the side close to the moving template as the front surface, the same below), and the mold clamping link 3 passes through the mold locking hole 11 and is aligned with the cylinder 2 along the axis of the mold clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com