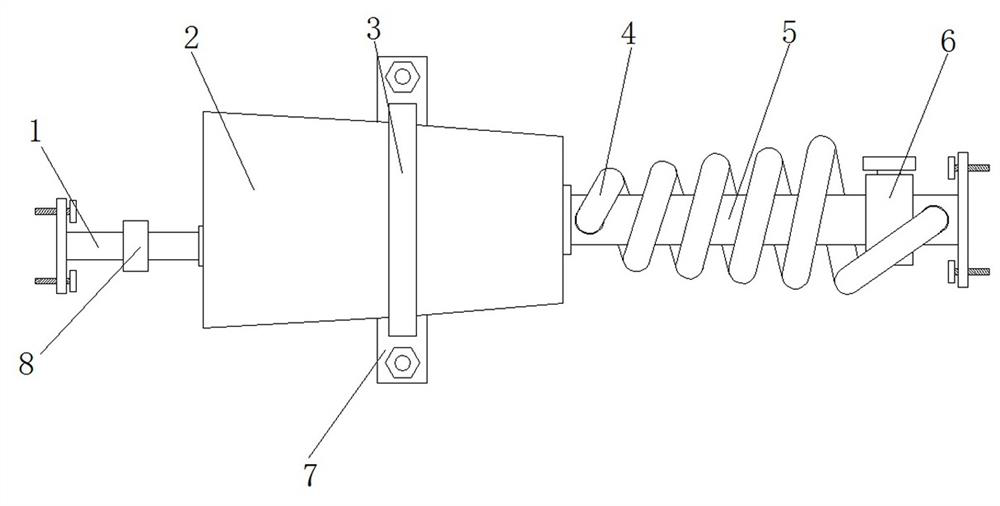

Silencer assembly of automobile exhaust system

A technology of automobile exhaust system and muffler, which is applied in the direction of exhaust device, muffler device, machine/engine, etc. It can solve the problems of reducing exhaust gas temperature, impossibility, and inconvenient installation, so as to reduce installation length, improve heat dissipation effect, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

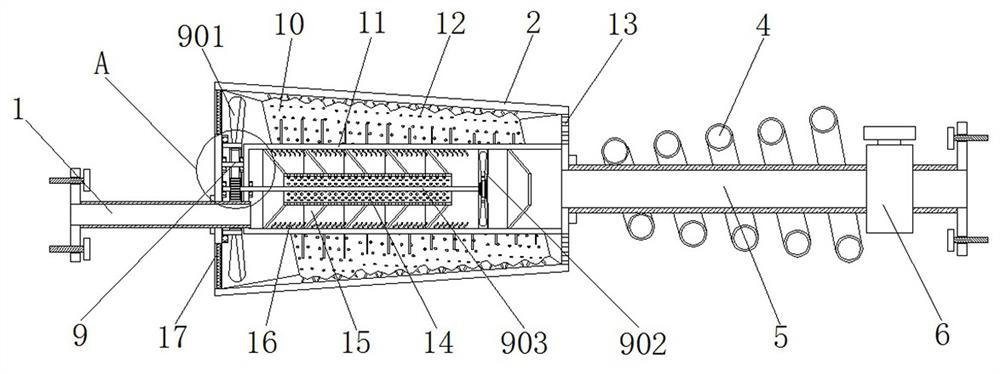

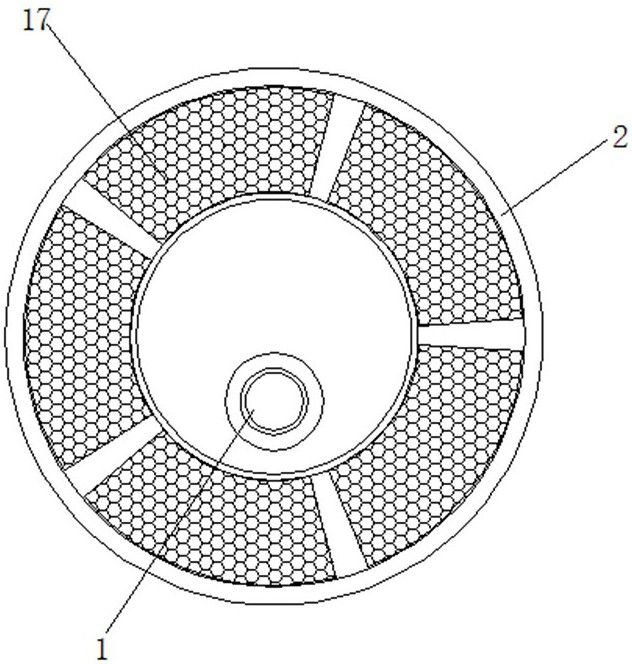

[0044] Example 1, such as Figure 1-7 As shown, the noise in the exhaust gas enters the cavity between the muffler pipe 11 and the annular partition 15 through the through hole 18, and due to the guidance of the annular partition 15, the sound waves are continuously absorbed between the two sets of annular partitions 15. consumption, and cooperate with the corrugated plate 16 on the inner wall of the muffler pipe 11 to reduce the noise, and part of the noise will be transmitted by the sound insulation layer 10 and the sound insulation layer 10 The holes 12 of the exhaust gas gradually disappear, and after the exhaust gas enters the heat exchange tube 4 through the muffler tube 11, the remaining noise in the exhaust gas will also be gradually eliminated by the inner wall of the heat exchange tube 4, thereby further reducing the The size of the noise after the exhaust gas is discharged also improves the noise reduction effect of the whole muffler assembly.

Embodiment 2

[0045] Example 2, such as Figure 1-7 As shown, after the exhaust gas is ejected from the air duct 14, it drives the fan 902 to rotate, and the fan 902 drives the rotating shaft 903 to rotate, and the rotating shaft 903 drives the rotating ring 908 and the fan blade 901 to rotate through the cooperation of the first gear 904 and the second gear 905 , use the rotating fan blade 901 to blow the outside air into the cavity between the protection chamber 2 and the muffler pipe 11, cool down the outside of the muffler pipe 11, close the control valve 6, and exhaust gas from the muffler pipe After the inside of 11 comes out, it can only be discharged from the inside of the heat exchange tube 4, while the air blown and cooled by the wind to the muffler tube 11 is ejected from the exhaust hole 13, and the air blown out from the exhaust hole 13 will blow to the heat exchange tube 4, the outside of the heat exchange tube 4 is cooled by wind blowing, thereby also reducing the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com