Rotary squeezing filling pile and pile-forming method therefor

A cast-in-situ pile and pile-forming technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems affecting construction speed, environmental pollution, noise pollution, etc., and achieve reliable hole quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

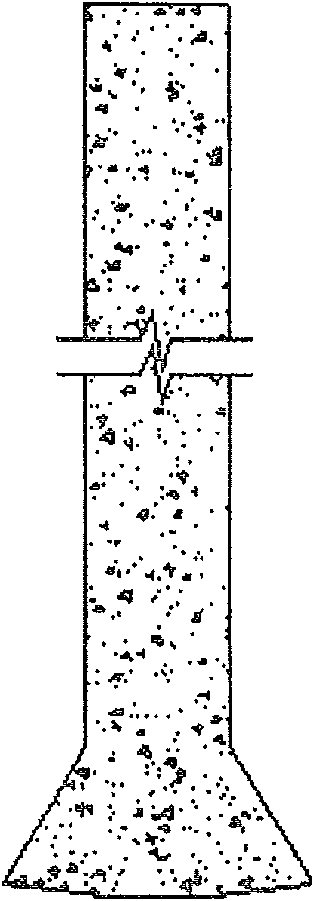

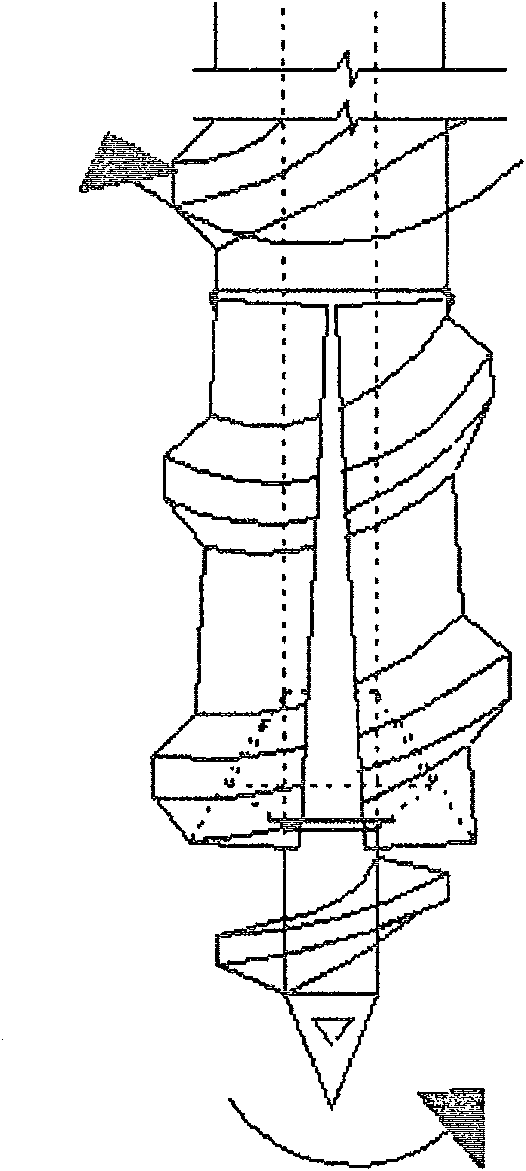

[0047] One-time rotary extrusion grouting pile consists of two parts, such as figure 1 As shown, the upper part of the pile is a linear cylinder with equal diameter, and the lower part of the pile is an enlarged head vertebral body, and the diameter of the enlarged head vertebral body is between 1.0-2.0 times the diameter of the cylinder.

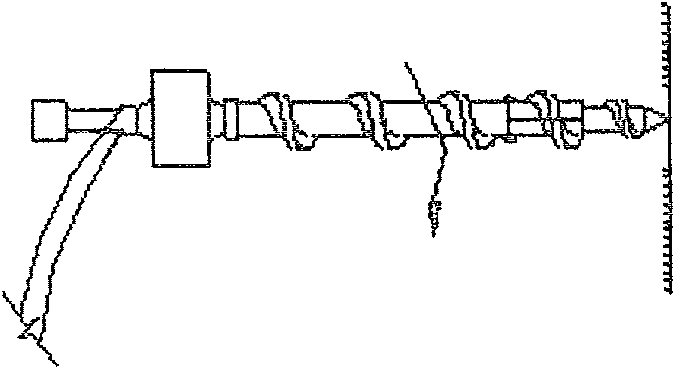

[0048] Depending on the stratum, the diameter can also be kept constant, and the pile-forming equipment described in Patent Application No. 200610019756.6 is adopted, and the drilling rig of the pile-forming equipment is changed into a pile construction method for one-time pile-forming construction. The specific steps are as follows:

[0049] 1. Use the pile-forming equipment described in the patent application number: 200610019756.6 to carry out the pile-forming method according to the following steps: Step 1: Use the pile-forming equipment described in the application number: 200610019756.6 to align the pile position, and the longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com