Construction method of deep and large-caliber gas extraction well

A technology of gas drainage and construction method, which is applied in the direction of drilling equipment and methods, mining fluids, earthwork drilling, etc., can solve the problems of difficulty in underground gas drainage with high content, improve equipment utilization rate and construction capacity, reduce Small energy consumption, little effect of geological conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

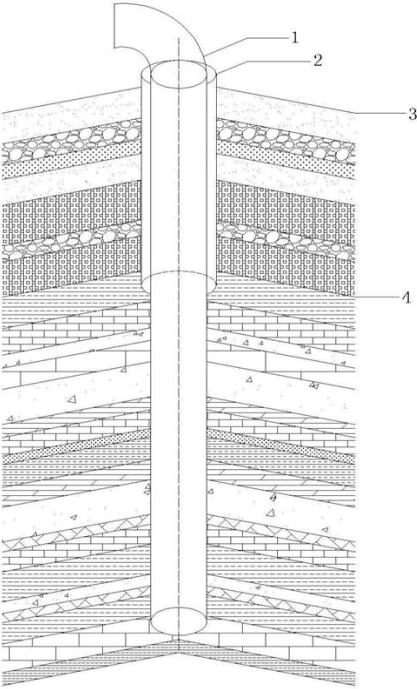

[0030] The underground gas drainage well is an independent channel system, which is widely used in coal mines and non-coal mines, especially underground mines. The depth is generally 600-900m, the drilling diameter is Ф800-1300mm, and the whole well is installed and fixed with Ф630-Φ1000*18mm seamless steel pipe or Q345B straight seam double-sided submerged arc welded steel pipe.

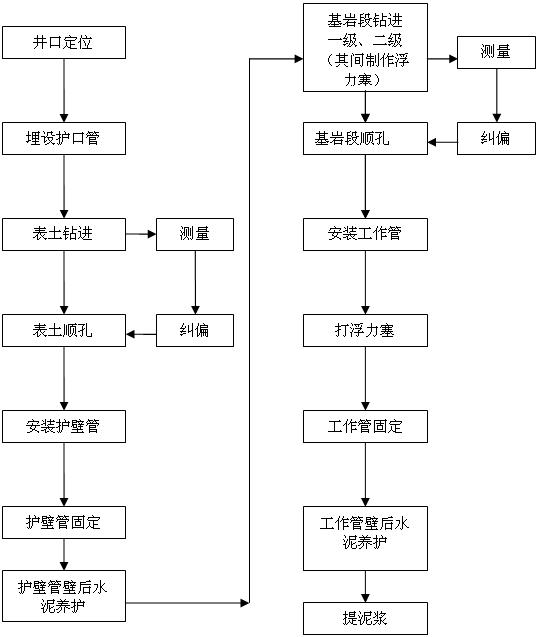

[0031] Construction method

[0032] 1. Fixing of the orifice pipe: fix the long orifice pipe vertically in the formation at the designated position of the drill hole and 200mm above the ground surface, fill the surrounding area with cement mortar, cut the mud outlet in the direction of the slurry, and its cross section is the same as the mud ditch groove. After the chassis of the drilling rig is installed, divide the orifice pipe into four points equally with the disc element, and fix it with the chassis to prevent the orifice pipe from falling into the hole during construction;

[0033] 2. Open-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com