Construction method of separable fulcrum pile

A construction method and separate technology, applied in sheet pile walls, foundation structure engineering, roads, etc., can solve the problems of step-by-step cast-in-place frames affecting the construction period, achieve good wall protection effect, shorten construction period, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

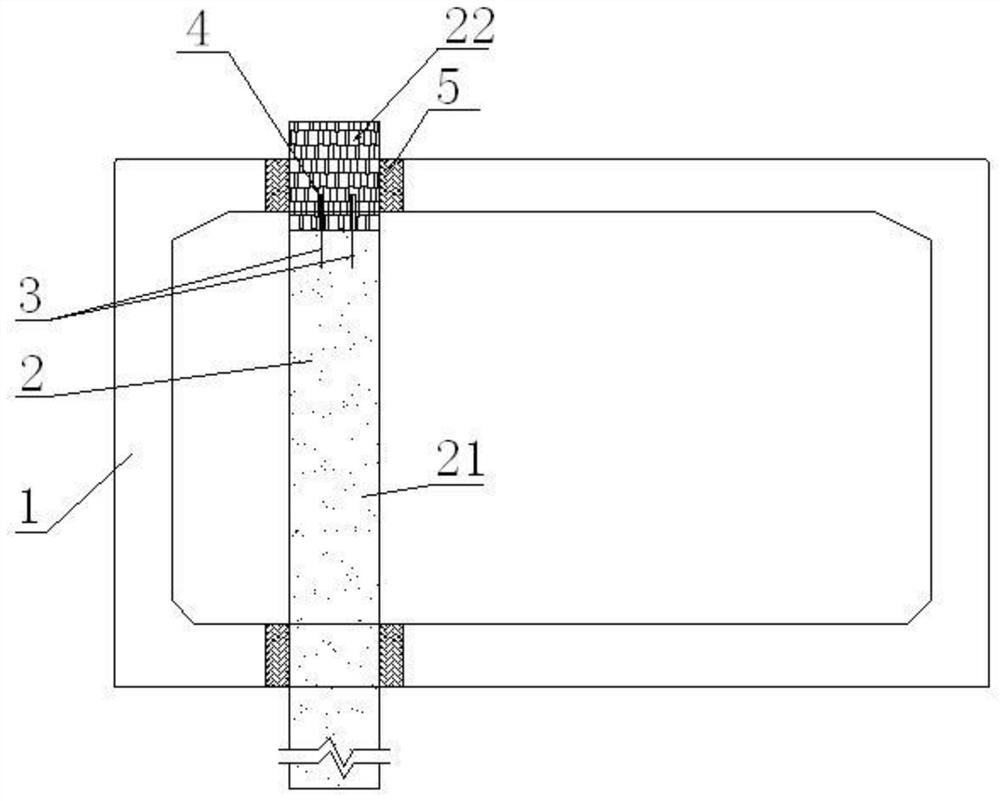

[0033] As shown in the accompanying drawings, the fulcrum pile passes through the box culvert 1, and the upper part of the fulcrum pile extends into the top floor of the box culvert, which is difficult to remove, so a detachable fulcrum pile is designed.

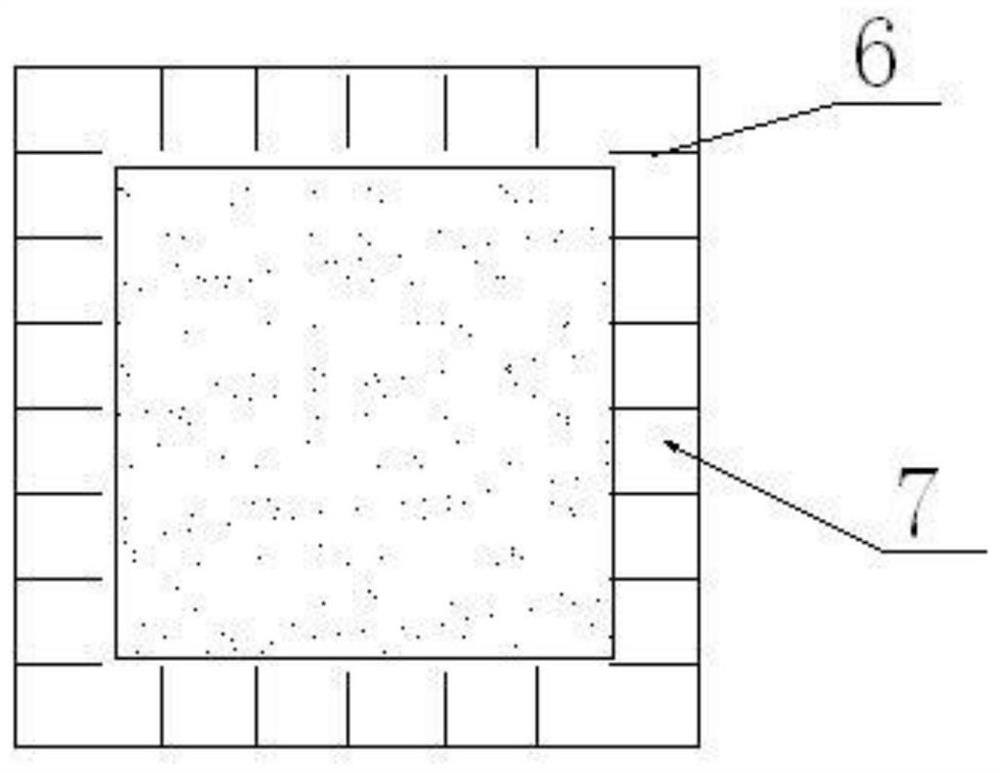

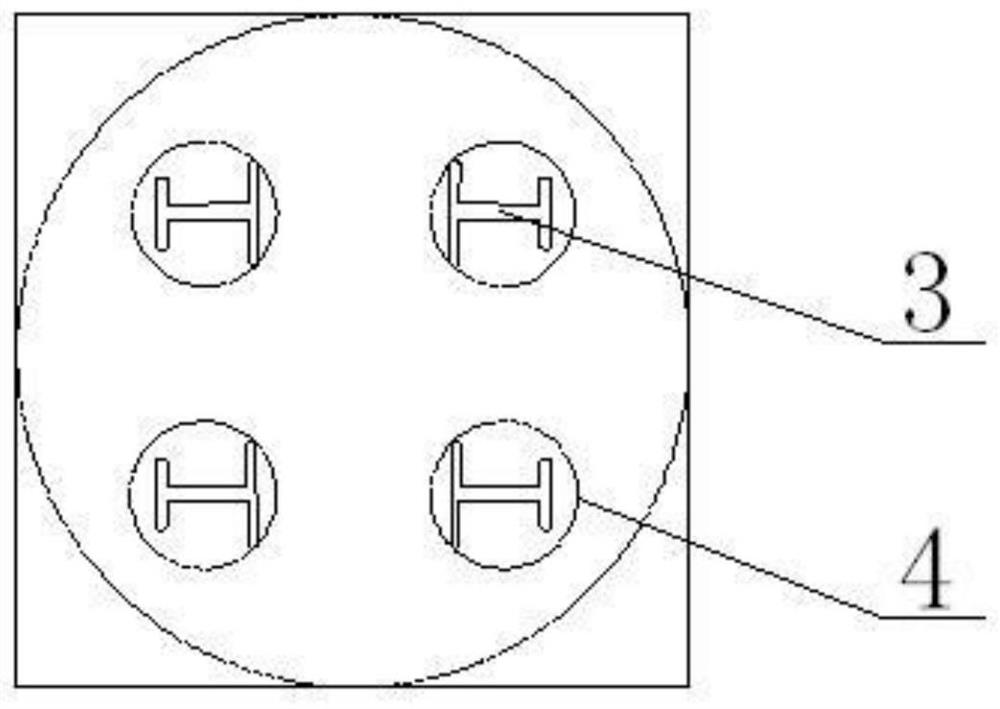

[0034] The detachable fulcrum pile 2 adopts the bored pile construction technology to form a pile, and the detachable fulcrum pile 2 includes a pile body 21 at the bottom and a pile head 22 at the top of the pile body 21 . Each detachable fulcrum pile 2 is provided with four steel rails 3 on the upper end of the pile body 21, and the steel rails 3 are arranged parallel to the center line of the fulcrum pile. Inside the pile head 22 , a PVC sleeve 4 is sheathed on the outside of the steel rail 3 inside the pile head 22 . In the present embodiment, steel rail 3 adopts P43 steel rail, and the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com