Compressor and operation method

A method of operation and compressor technology, which is applied to mechanical equipment, machines/engines, rotary piston pumps, etc., can solve the problems of reduced filter function, excessive loss of mechanical parts, pollution, etc., and achieve the effect of avoiding backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below with reference to the drawings.

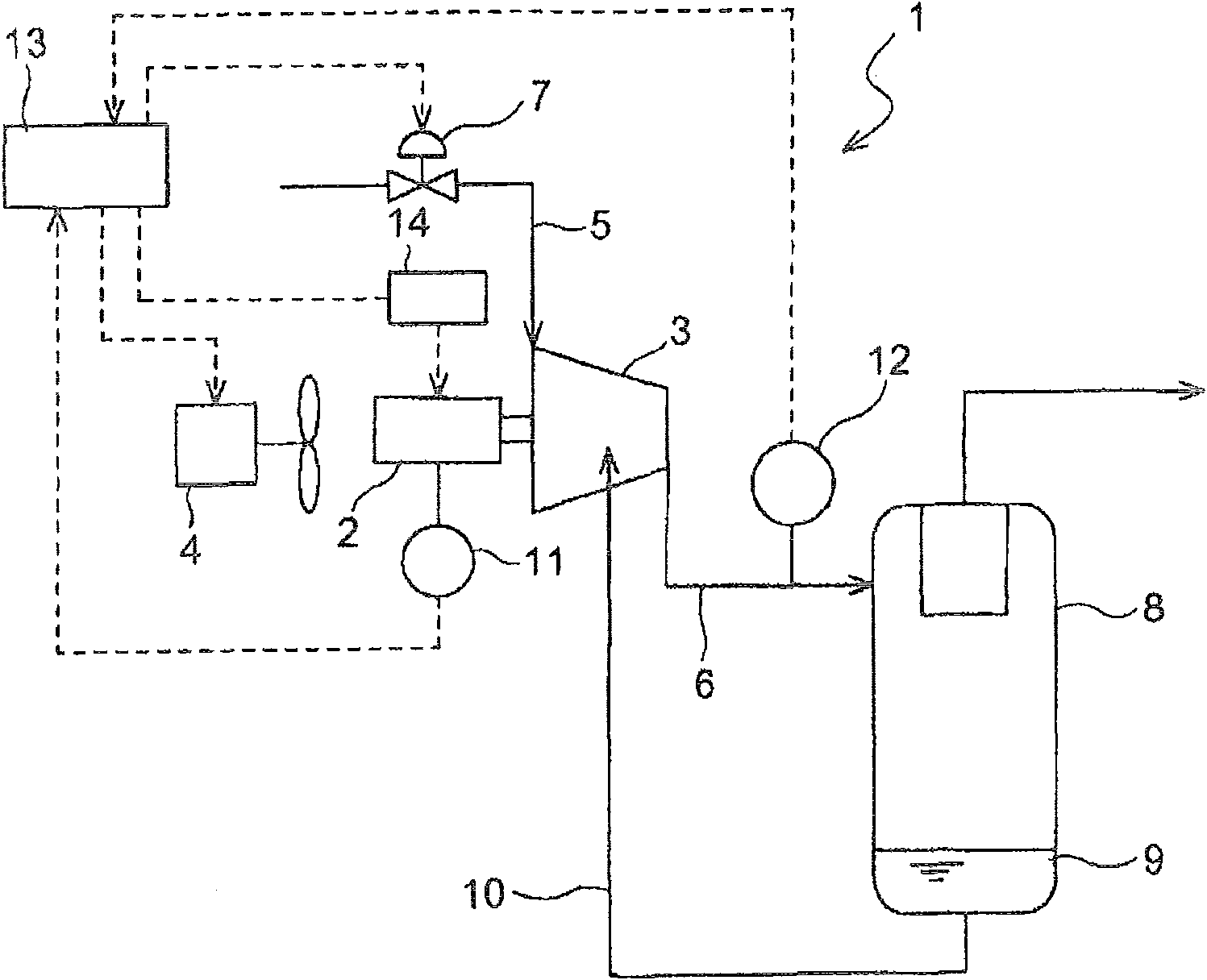

[0020] figure 1 An oil-cooled screw compressor 1 according to an embodiment of the present invention is shown. The oil-cooled screw compressor 1 has a compressor main body 3 in which a pair of male and female screw rotors driven by a motor 2 and engaged with each other are accommodated. In the vicinity of the motor 2 of the compressor body 3 , a cooling fan 4 is provided so as to blow air toward the motor 2 . A suction flow path 5 is connected to one side of the compressor main body 3 , and a discharge flow path 6 is connected to the other side. An on-off valve 7 is provided in the suction flow path 5 . An oil separator 8 is provided in the discharge flow path 6 . Extending from the oil storage part 9 at the lower part of the oil separation and recovery device 8 is an oil flow path 10 communicating with the oil supply parts such as the rotor chamber, the bearing part and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com