Wash tank of device for continuously cleaning strip

A technology for cleaning equipment and cleaning tanks, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of cleaning liquid leakage, mutual interference of cleaning liquids, and inconvenient installation, etc., to eliminate corrosion, It is convenient for automatic production and has the effect of preventing cleaning fluid from leaking out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

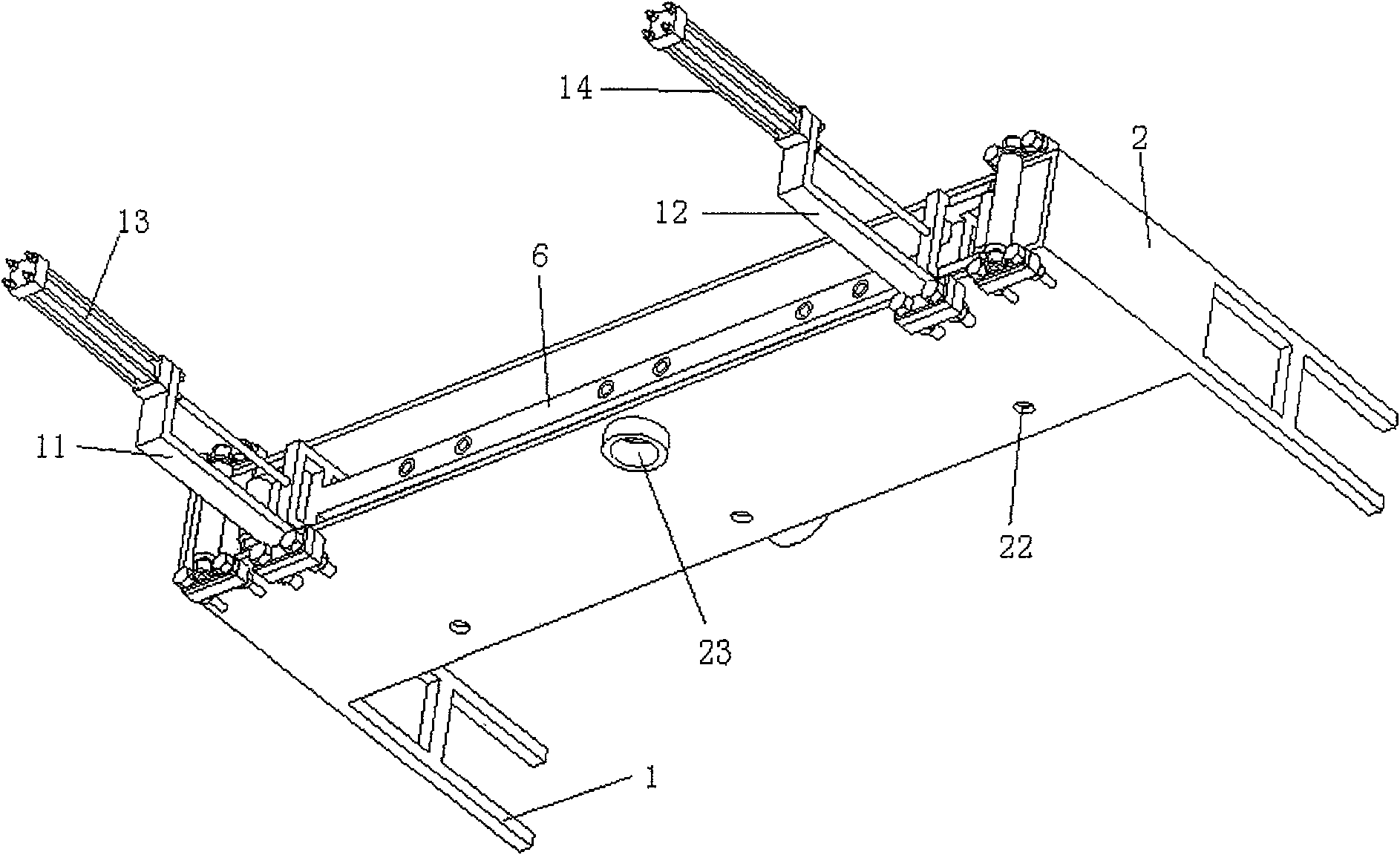

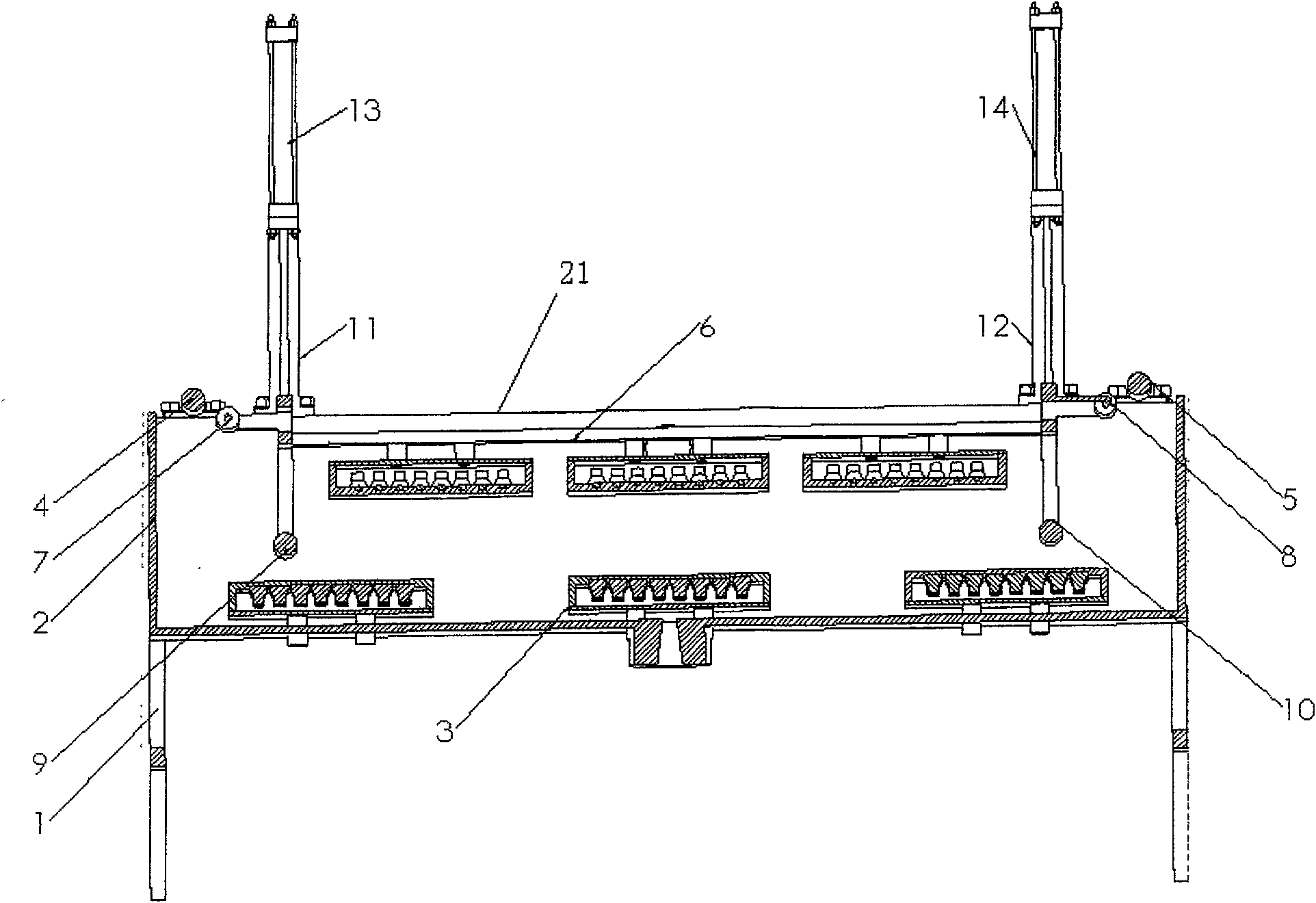

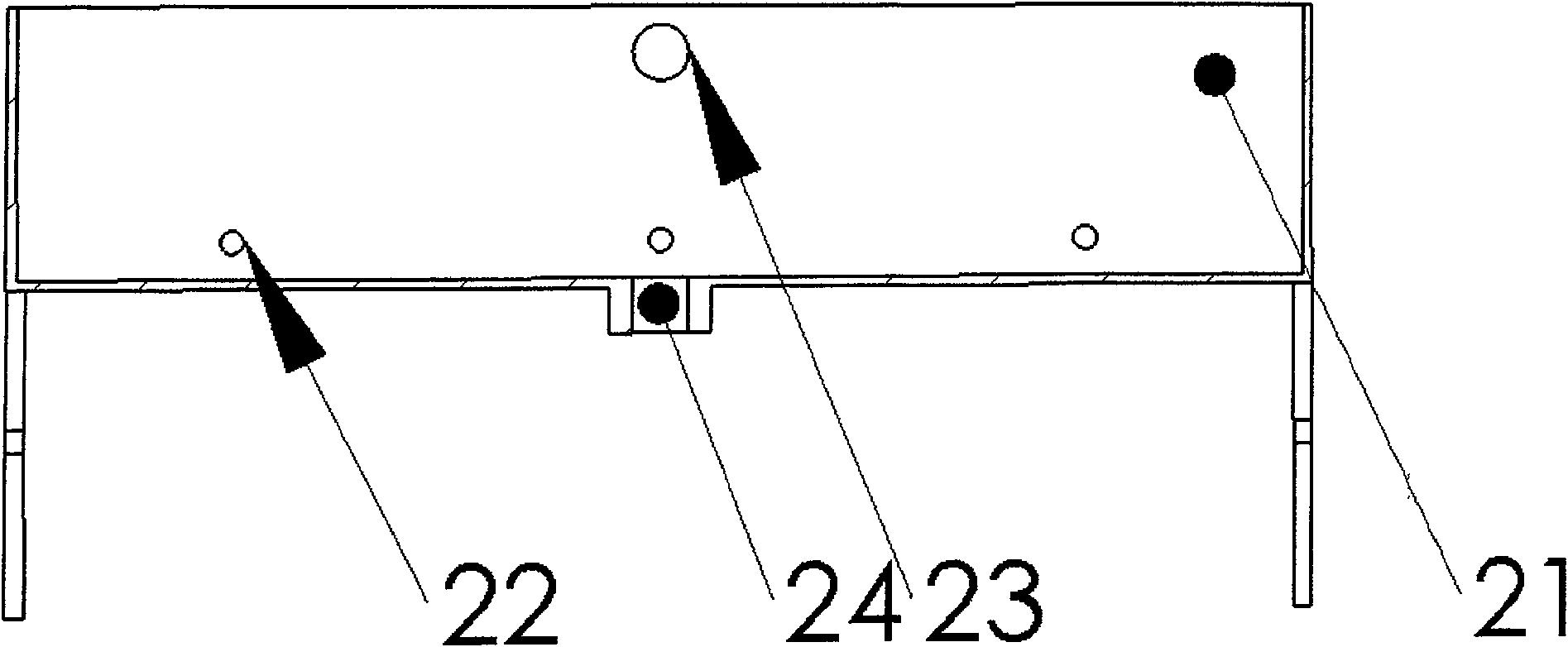

[0020] see figure 1 , figure 2 , image 3 and Figure 4 As shown, a cleaning tank of a strip continuous cleaning equipment is composed of a chamber, and an ultrasonic vibrating plate is arranged inside. The specific composition is as follows:

[0021] It includes a frame 1 and a tank body 2 arranged on the frame 1; on the tank body 2, a water cutting roller 4 on the lower surface of the left strip material and a water cutting roller 5 on the lower surface of the right strip material are arranged symmetrically on the left and right sides of the tank body 2. In addition, a left cylinder support 11 and a right cylinder support 12 are also symmetrically fixed on the rear plate 21 on the tank body 2, and the left cylinder 13 and the right cylinder 14 are installed on the left cylinder support 11 and the right cylinder support 12 respectively. Above, their telescopic shafts are jointly connected on a support roller bracket 6, and the up and down movement of the telescopic shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com