Self-lock type zip head

A zipper puller and self-locking technology, which is applied in the field of zipper pullers, can solve the problems of increasing the difficulty of zipper puller assembly, difficulty in positioning, and failure to effectively fix the holding shrapnel, so as to facilitate automatic mechanical assembly, reduce assembly difficulty, and self-locking firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

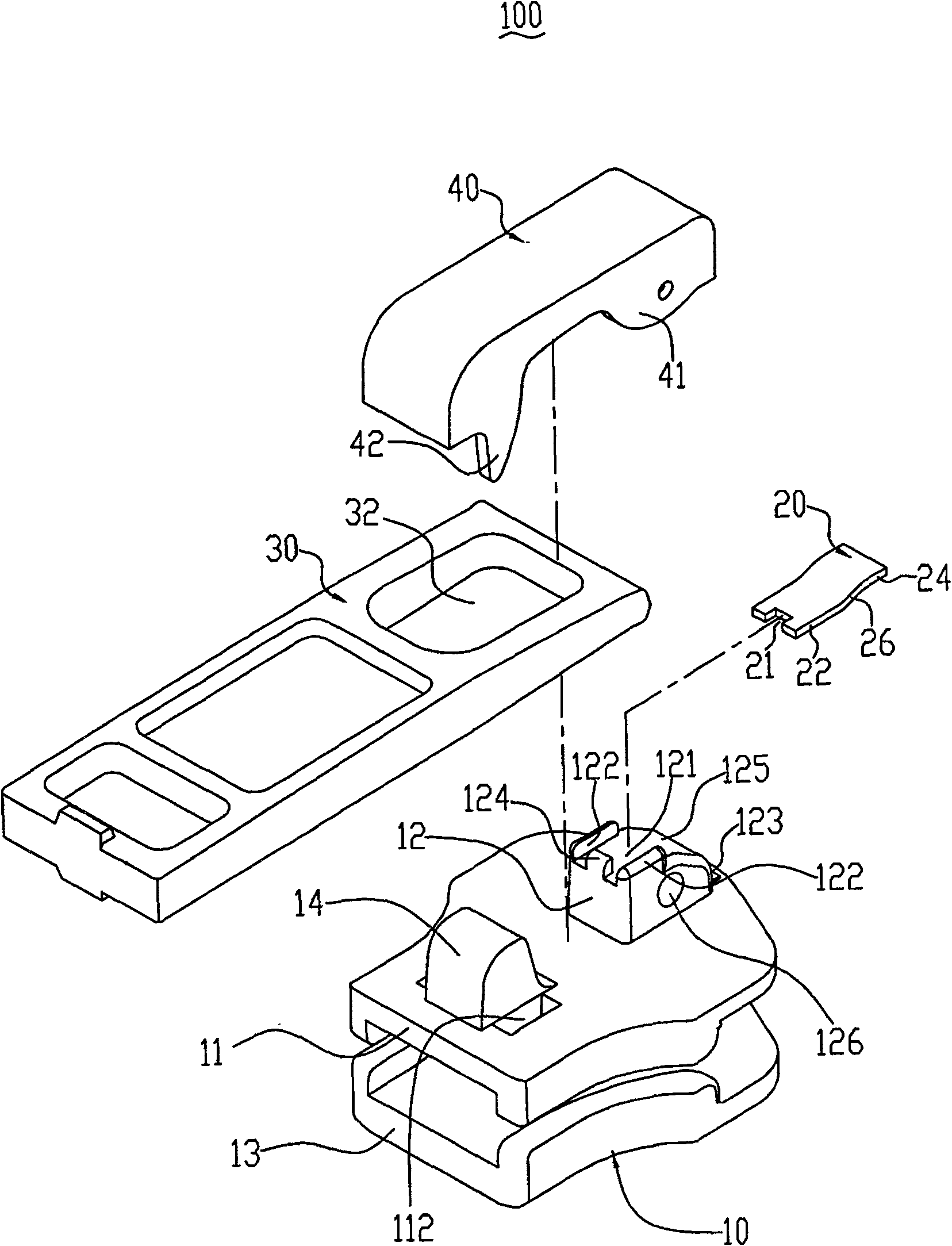

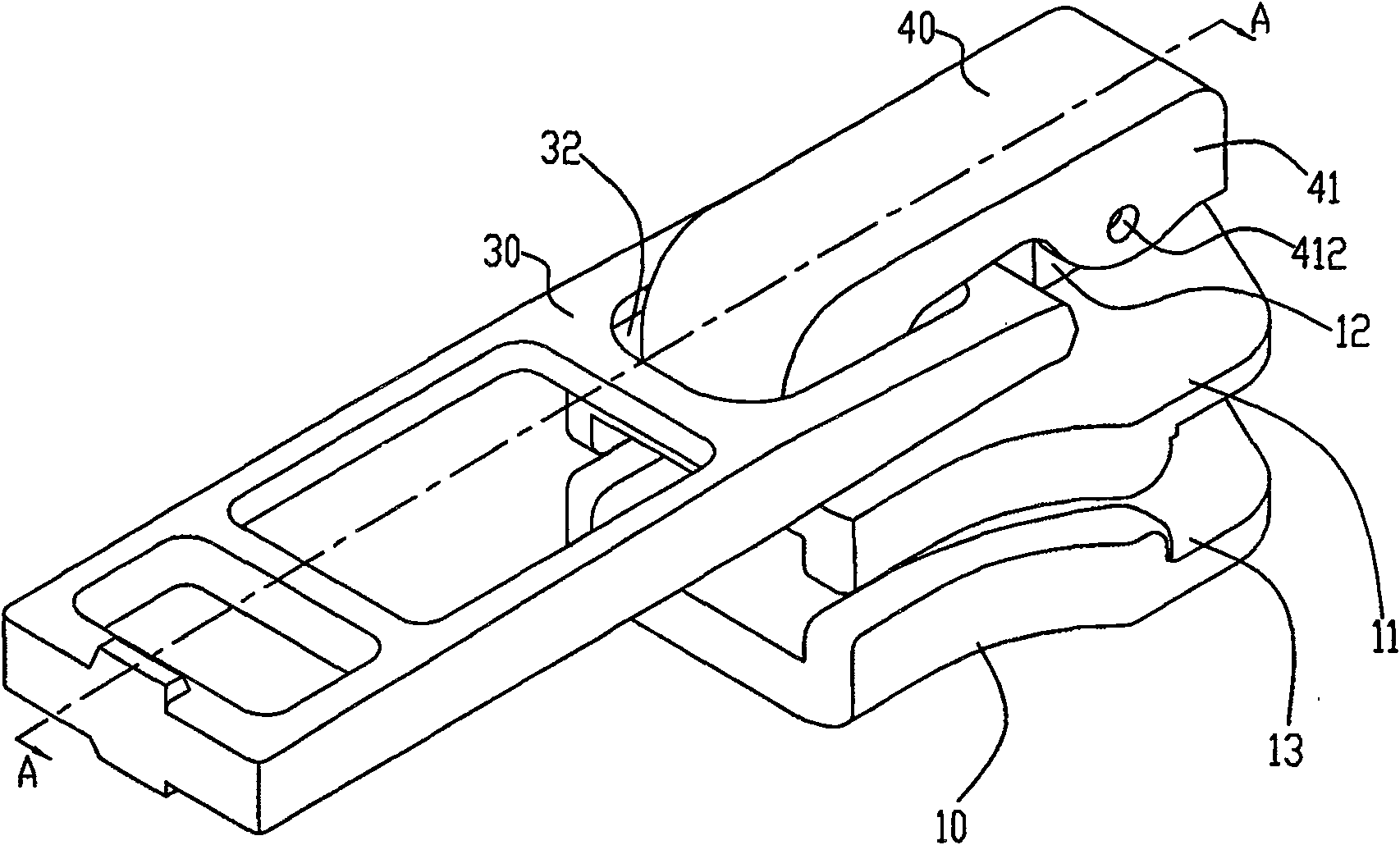

[0015] figure 1 Shown is a three-dimensional exploded view of the self-locking zipper puller 100 according to the first embodiment of the present invention. The zipper slider 100 includes a slider 10 , an elastic piece 20 , a pull piece 30 and a cap 40 . The elastic piece 20 and the cap 40 are respectively fixed on the slider 10 , and the pull piece 30 is sleeved on the cap 40 .

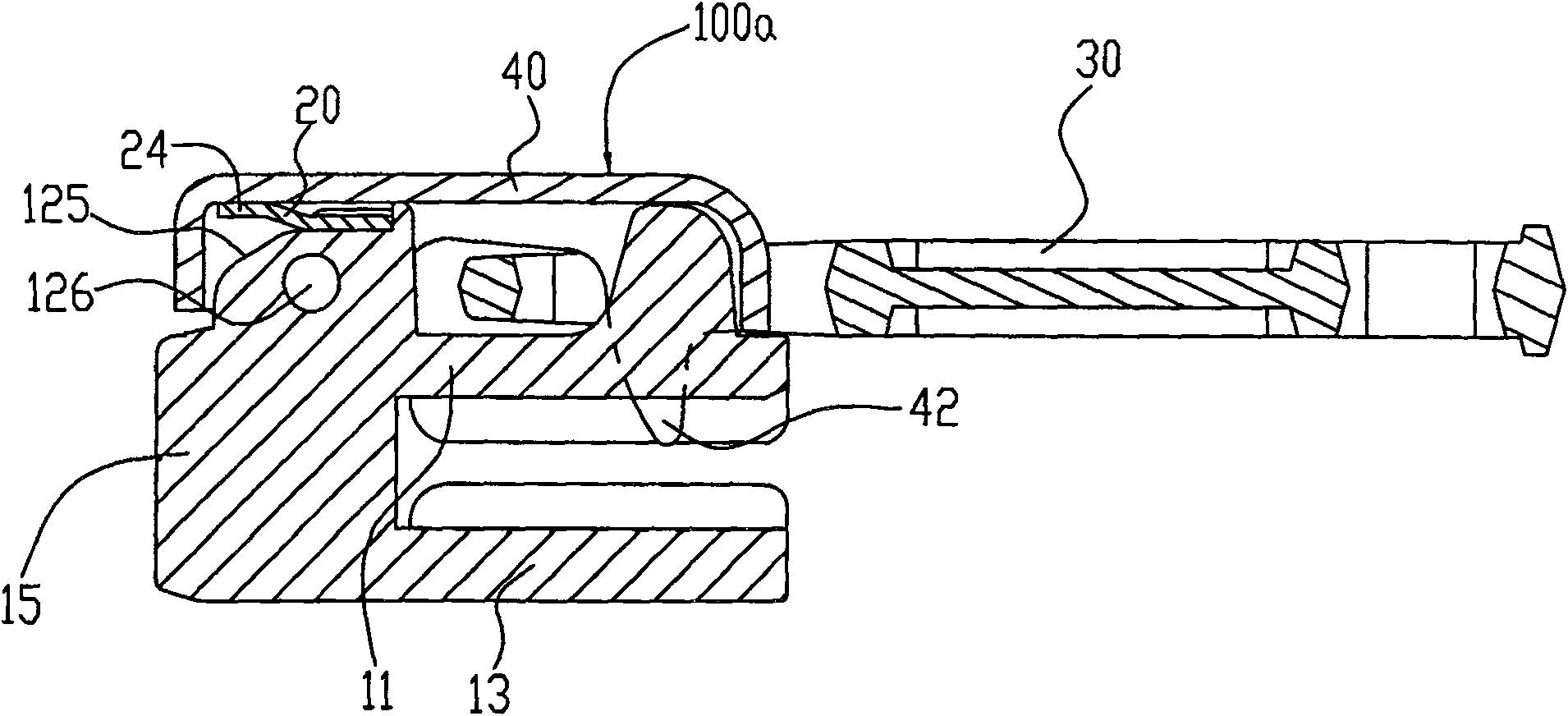

[0016] The slider 10 is made of metal material, and includes an upper wing 11 and a lower wing 13 . Connect by a guide post 15 between this upper wing plate 11 and the lower wing plate 13 (as image 3 shown), so as to form a substantially Y-shaped slideway for the chain teeth (not shown) of a zipper to pass through. The upper wing 11 is provided with a connecting block 12 , a limiting block 14 and a through hole 112 . The connecting block 12 is located at the front end of the upper wing plate 11 , and the limiting block 14 and the through hole 112 are located at the rear end of the upper wing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com