Method for preparing boron nitride coating carbon nano-tube/nano-wire and boron nitride nano-tube

A boron nitride nanotube, boron nitride package technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems affecting the application of boron nitride nanotubes, metal pollution, low yield, etc., and achieve cost Low, high production efficiency, low reaction temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Coating boron nitride on the surface of carbon nanotubes or nanowires through the reaction of ammonium fluoroborate, and obtaining boron nitride nanotubes by oxidation: weigh 4.2g NH with a balance 4 BF 4 and 0.2g of carbon nanotubes or nanowires into a stainless steel reactor. After the reactor was sealed tightly, it was heated to 600°C in a heating furnace for 12 hours and then the heating was stopped, and the reactor was naturally cooled to room temperature in the furnace. The reaction product was washed with deionized water and filtered with suction to remove the residual reactant NH 4 BF 4 and reaction by-products until the filtrate is neutral, and the obtained product is dried at 60° C. for 8 hours to obtain boron nitride-coated carbon nanotubes or nanowires.

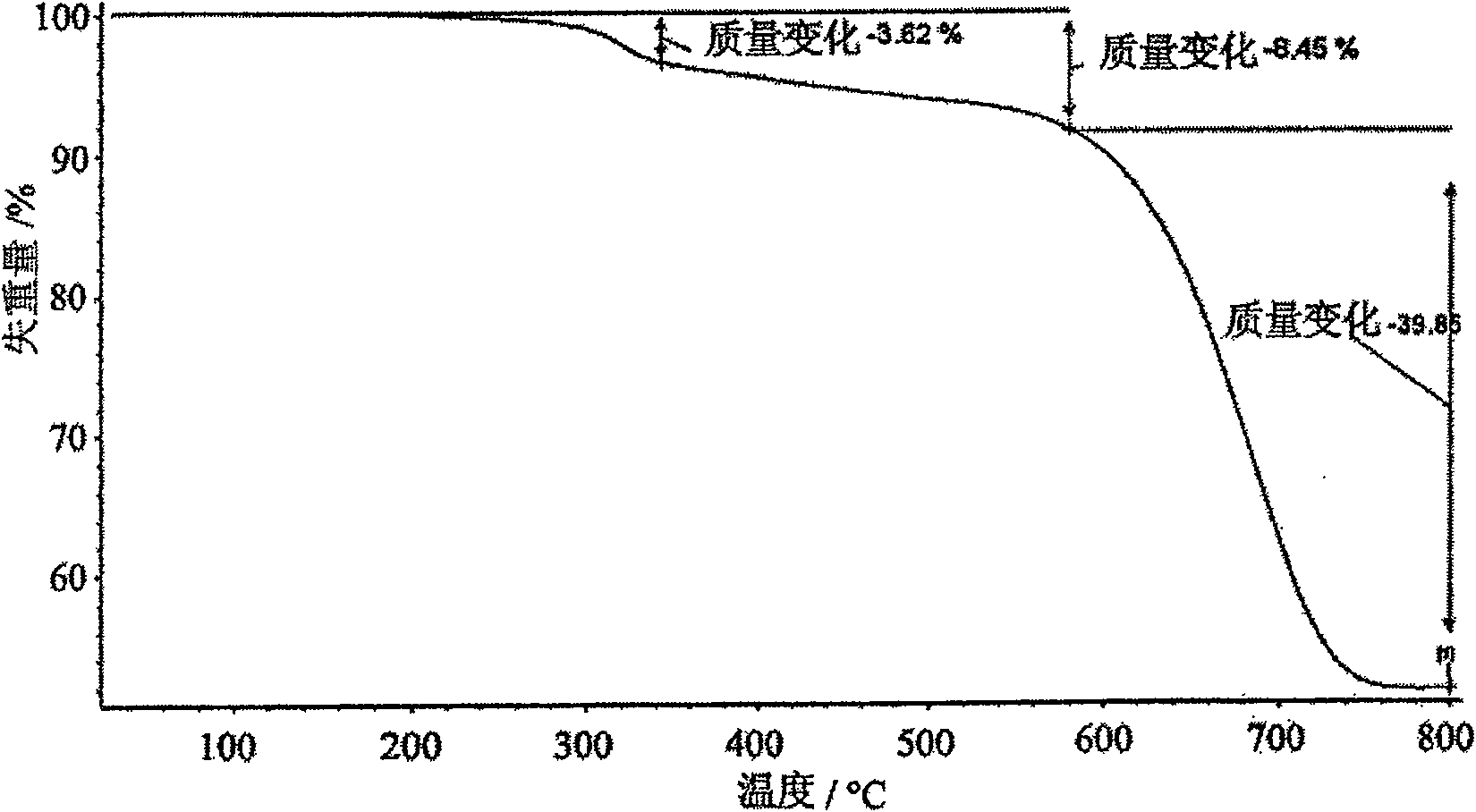

[0023] The boron nitride-coated carbon nanotubes or nanowires obtained above are heated to 750° C. in air for oxidation treatment to obtain boron nitride nanotubes.

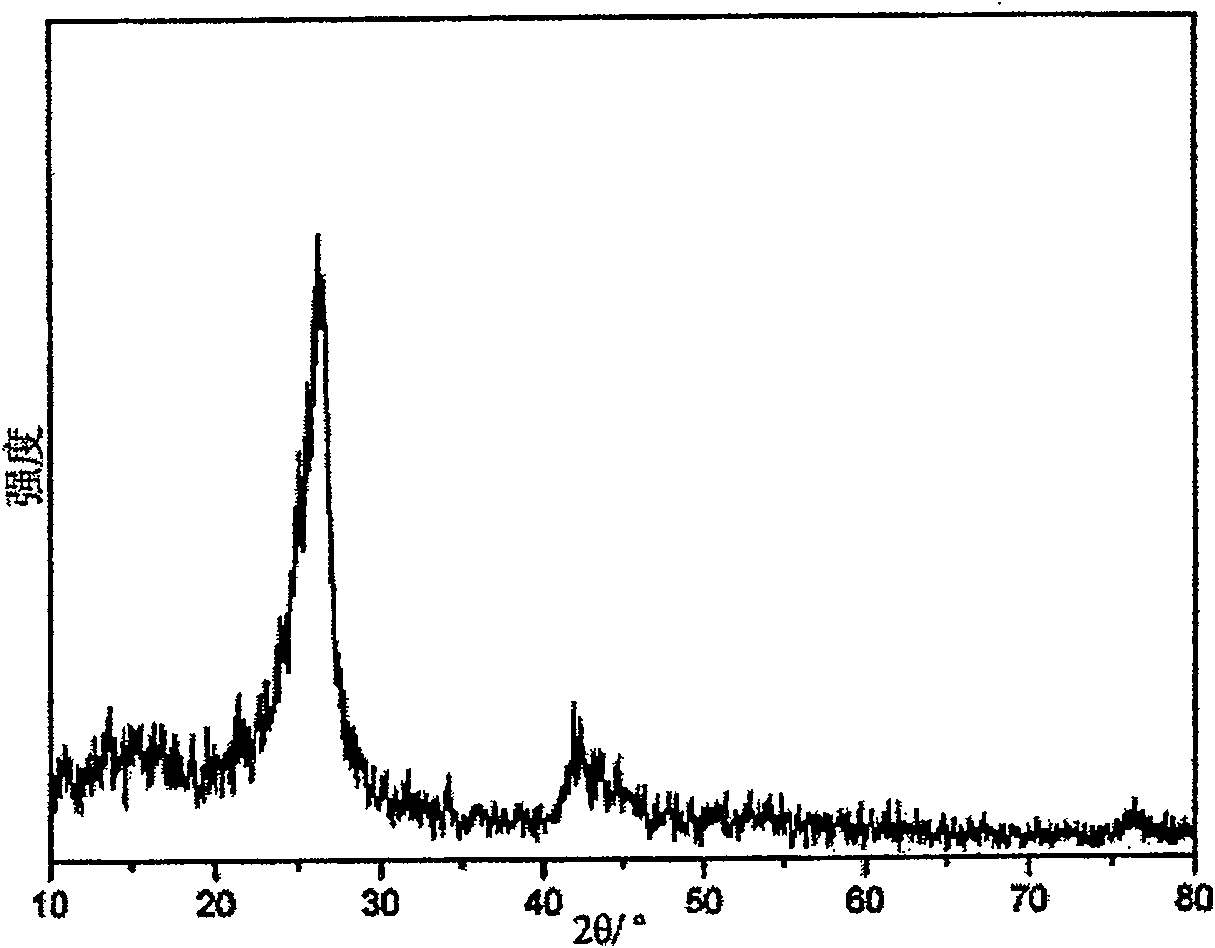

[0024] figure 1 Shown i...

Embodiment 2

[0025] Example 2: Coating boron nitride on the surface of carbon nanotubes or nanowires through the reaction of ammonium fluoroborate, and obtaining boron nitride nanotubes by oxidation: Weigh 4.2g NH with a balance 4 BF 4 and 0.2g of carbon nanotubes or nanowires into a stainless steel reactor. After the reaction kettle is tightly sealed, it is heated to 500° C. in a heating furnace for 18 hours, and then the heating is stopped, and the reaction kettle is naturally cooled to room temperature in the furnace. The reaction product was washed with deionized water and filtered with suction to remove the residual reactant NH 4 BF 4 until the filtrate is neutral, the obtained product is dried at 60° C. for 5 hours to obtain boron nitride-coated carbon nanotubes or nanowires.

[0026] The boron nitride-coated carbon nanotubes or nanowires obtained above are heated to 800° C. in air for oxidation treatment to obtain boron nitride nanotubes.

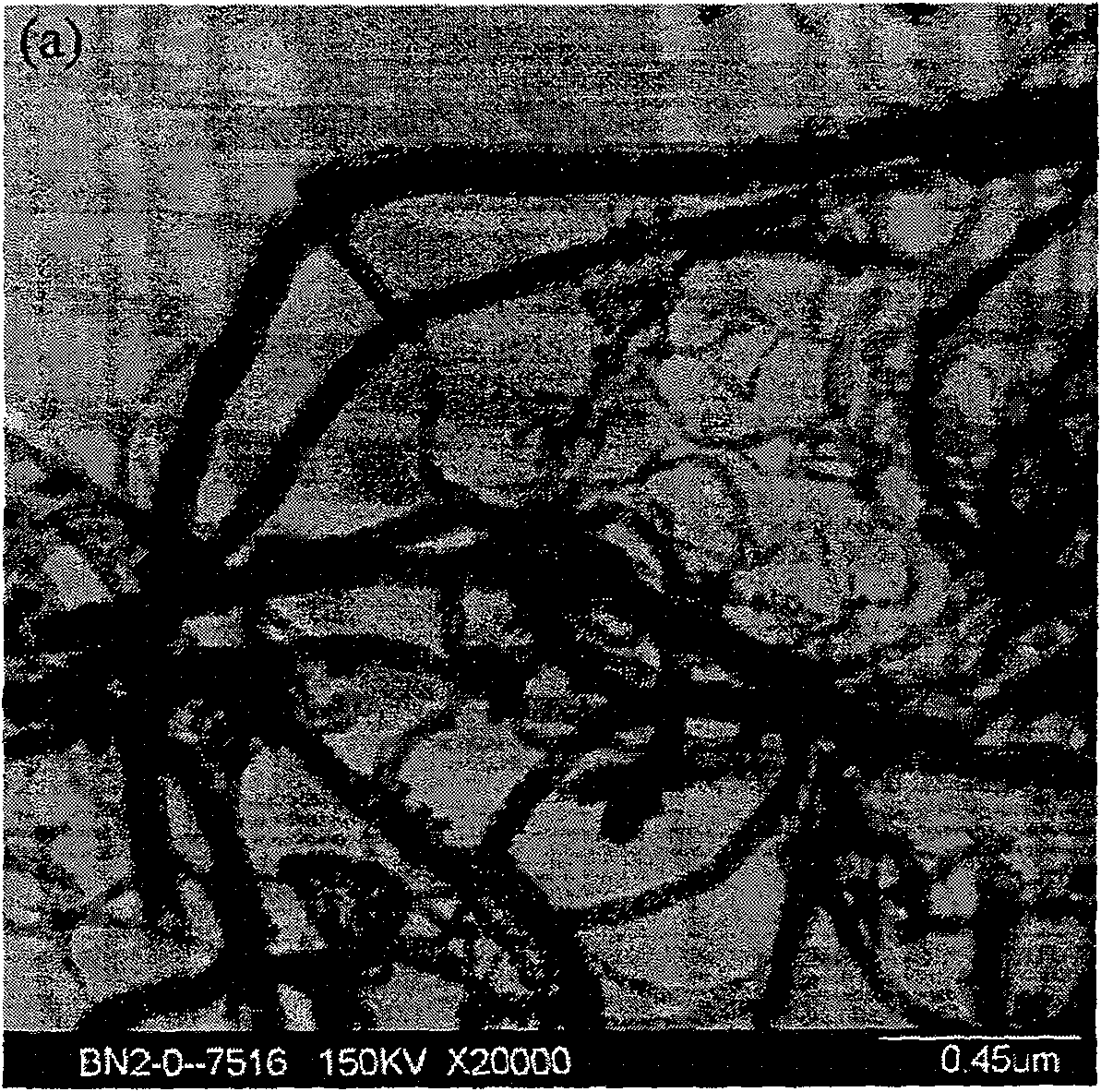

[0027] image 3 Shown is the TEM topo...

Embodiment 3

[0028] Example 3: Coating boron nitride on the surface of carbon nanotubes or nanowires through the reaction between sodium borohydride and ammonium chloride, and obtaining boron nitride nanotubes by oxidation: Weigh 1.5g NaBH with a balance 4 , 2.2 g NH 4 Cl and 0.2g carbon nanotubes or nanowires are loaded into a stainless steel reactor. After the reaction kettle is tightly sealed, it is heated to 530° C. in a heating furnace for 16 hours and then the heating is stopped, and the reaction kettle is naturally cooled to room temperature in the furnace. The reaction product was washed with deionized water and suction filtered to remove the residual reactant NaBH 4 , NH 4 Cl and reaction by-product NaCl until the filtrate is neutral, the obtained product is dried at 70°C for 5 hours, and heat-treated at 800°C to obtain boron nitride-coated carbon nanotubes or nanowires.

[0029] The boron nitride-coated carbon nanotubes or nanowires obtained above are heated to 770° C. in air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com