Method for synthesizing (S)-toliprolol

A synthesis method and technology of molar ratio, applied in the field of synthesis of tolirolol, can solve the problems of unfavorable industrial application, low optical purity, low yield, etc., and achieve good industrial application prospects, high optical purity and high yield , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

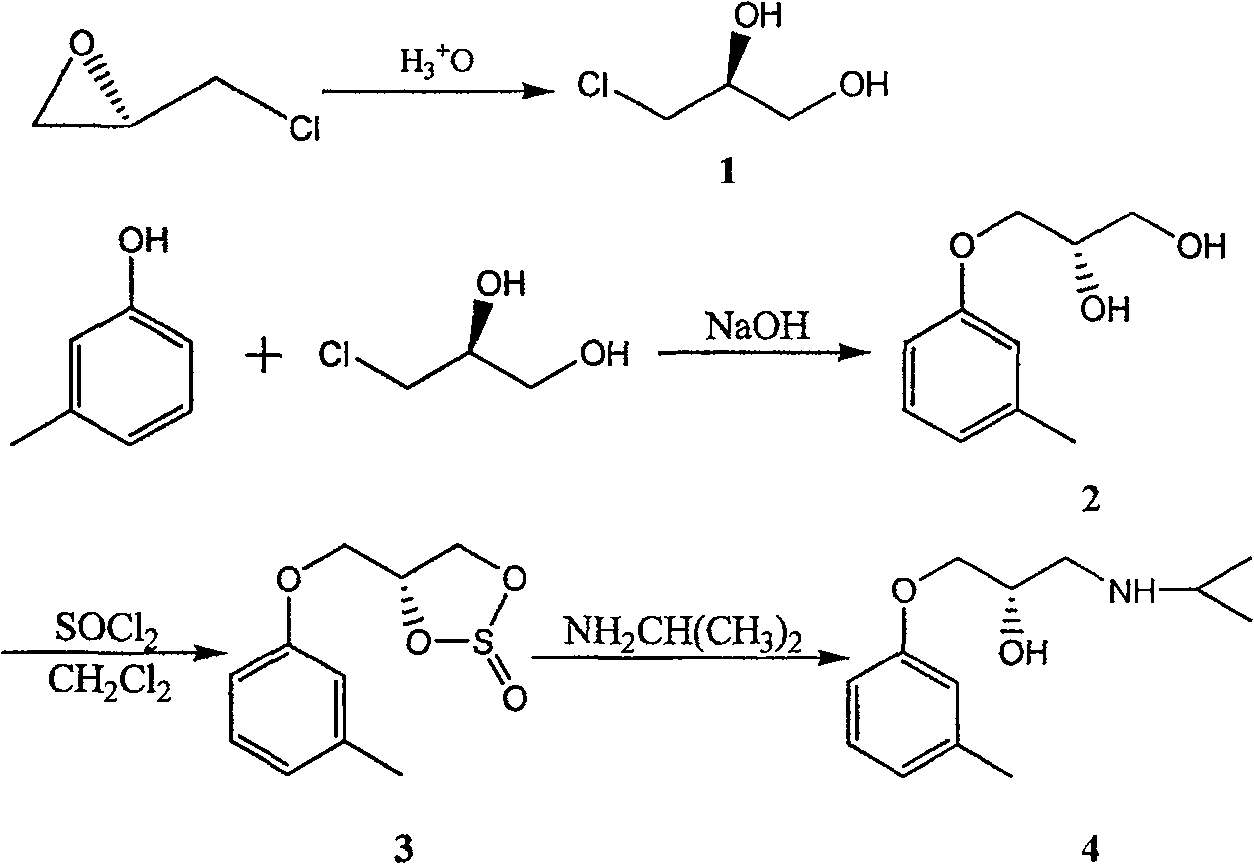

[0024] Embodiment 1: the preparation of (S)-tolilool (compound 4)

[0025] (1) Preparation of compound 1 [(S)-3-chloro-1,2-propanediol]

[0026] The temperature of 2% dilute sulfuric acid (120g, 0.024mol) was slowly raised to 80°C, (S)-epichlorohydrin (160mL, 2.043mol) was added dropwise, and the temperature was controlled at 100-105°C for 2 hours. Cool to room temperature, adjust the pH to 7 with 30% sodium hydroxide solution in a water bath, concentrate under reduced pressure to remove water, then distill under reduced pressure, collect fractions at 130-136°C / 2.67KPa to obtain a colorless viscous liquid (S)-3-chloro-1,2-propanediol 168g, productive rate 76.5%, experimental data is as follows:

[0027] Gas chromatography content: 99.4% (analysis conditions: AT SE-30 capillary column with column length 30m and diameter 0.25mm; hydrogen flame detection; column temperature: 180°C, monitor temperature: 230°C; carrier gas is N 2 , flow rate: 30ml / min, hydrogen flow rate: 1.5ml / m...

Embodiment 2

[0038] (1) Preparation of compound 1 [(S)-3-chloro-1,2-propanediol]

[0039] Slowly heat up 2% dilute sulfuric acid (60g, 0.012mol) to 70°C, add (S)-epichlorohydrin (160mL, 2.043mol) dropwise, and react at a temperature of 80-90°C for 3 hours. Cool to room temperature, adjust the pH to 7 with 25% potassium hydroxide solution in a water bath, concentrate under reduced pressure to remove water, and then distill under reduced pressure to collect fractions at 130-134°C / 2.67KPa to obtain a colorless viscous liquid (S)-3-chloro-1,2-propanediol 162g, productive rate 73.8%, experimental data is as follows:

[0040] Gas chromatography content: 99.6% (analysis conditions: AT SE-30 capillary column with column length 30m and diameter 0.25mm; hydrogen flame detection; column temperature: 180°C, monitor temperature: 230°C; carrier gas is N 2 , flow rate: 30ml / min, hydrogen flow rate: 1.5ml / min); [α] D 20 =+7.4(c 1.0, H 2 O).

[0041] (2) Preparation of compound 2 [(S)-3-m-tolyloxy-1,2...

Embodiment 3

[0048] (1) Preparation of compound 1 [(S)-3-chloro-1,2-propanediol]

[0049] Slowly heat up dilute sulfuric acid (130g, 0.02mol) with a concentration of 1.5% to 60°C, add (S)-epichlorohydrin (160mL, 2.043mol) dropwise, and react at a temperature of 105-110°C for 1 hour. Cool to room temperature, adjust the pH value to 7 with sodium carbonate in a water bath, concentrate under reduced pressure to remove water, and then distill under reduced pressure to collect fractions at 130-136°C / 2.67KPa to obtain colorless viscous liquid (S)-3-chloro -1,2-propanediol 170g, productive rate 77.4%, gas chromatographic content: 99.6% (analysis conditions are: column length 30m, the AT SE-30 capillary column of diameter 0.25mm; Hydrogen flame detection; Column temperature: 180 ℃, Monitor temperature: 230°C; carrier gas is N 2 , flow rate: 30ml / min, hydrogen flow rate: 1.5ml / min); [α] D 20 =+7.3(c 1.0, H 2 O).

[0050] (2) Preparation of compound 2 [(S)-3-m-tolyloxy-1,2-propanediol]

[0051...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com